Preparation method of DOPO vinylidene bridged derivative, flame retardant and flame-retardant polymer material

A vinylidene bridge chain and derivative technology, applied in the field of flame retardant preparation, can solve the problems of high energy consumption of raw material backflow, difficult to obtain raw materials, low yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

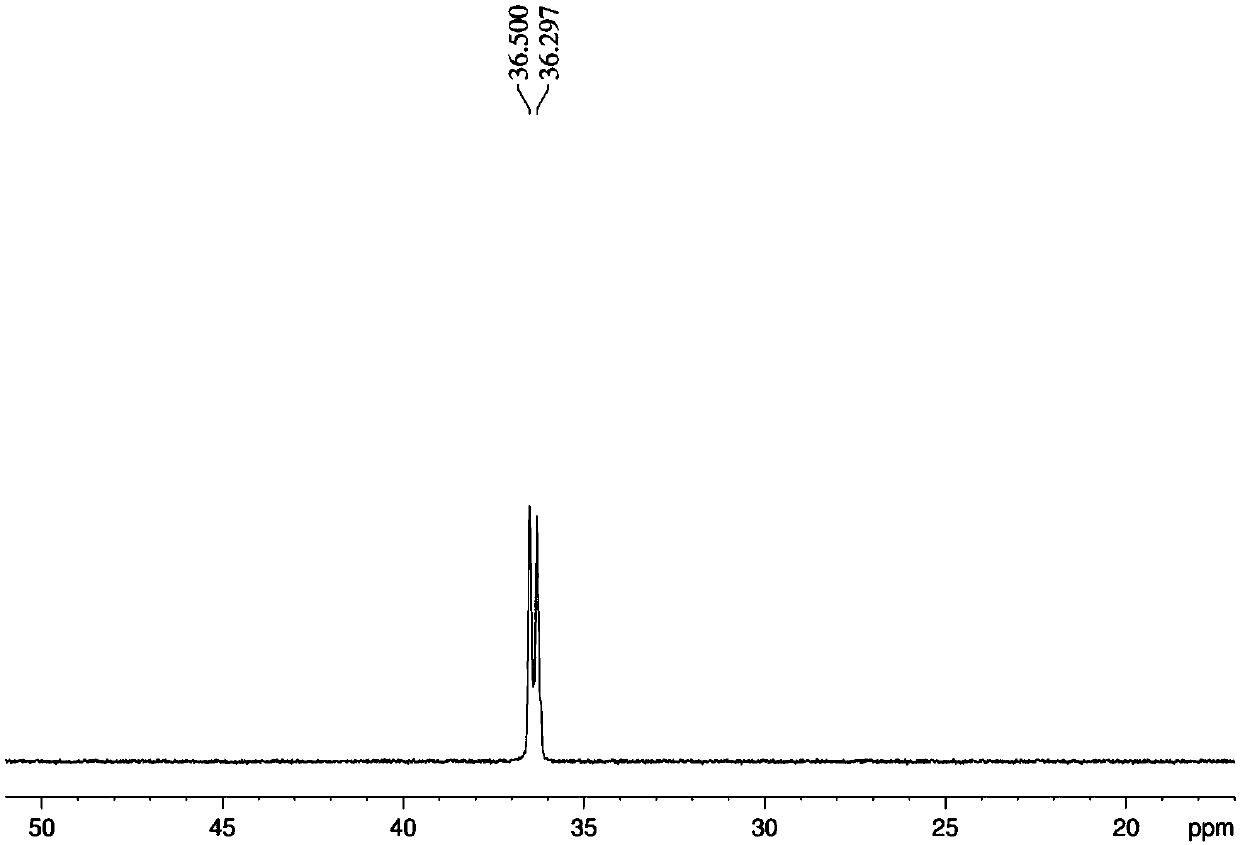

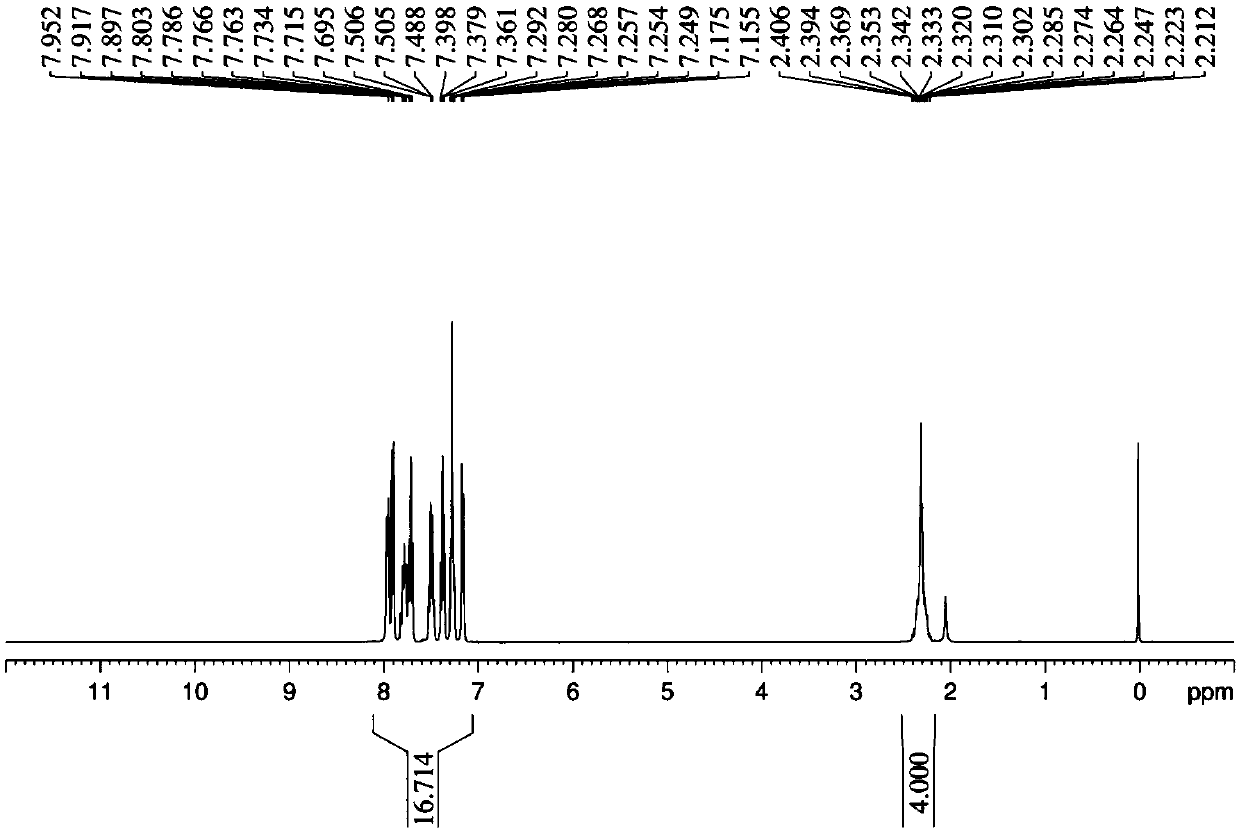

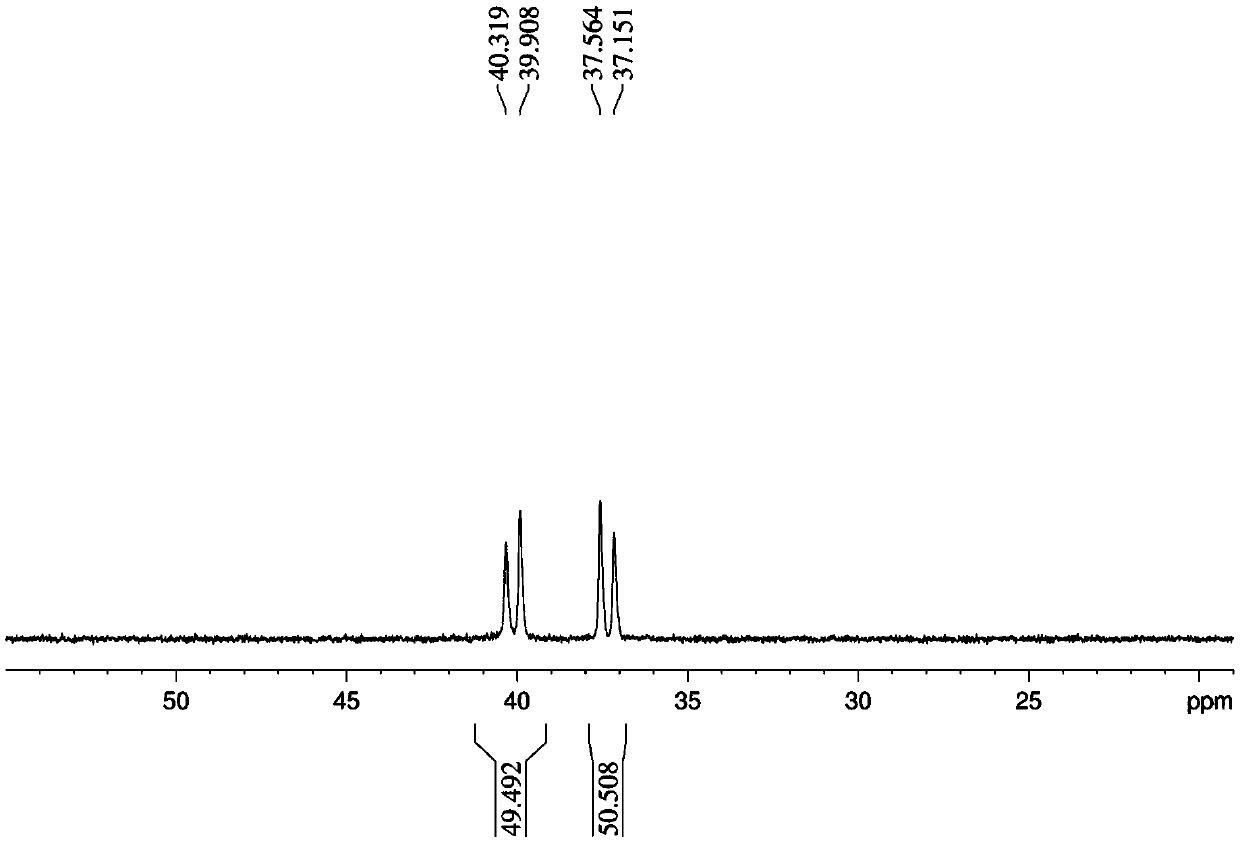

[0070] Example 1 Preparation of DOPO Bridged Derivatives of Formula (V) [6H-Dibenzo[c,e][1,2]Oxophosphoglyceride, 6,6'-(1,2-Ethylenediyl) bis-,6,6'-dioxide]

[0071] DOPO32.4g (0.15mol), diphenylmethane 25g and 20g xylene were added to a four-necked flask equipped with a thermometer, a water separator, a mechanical stirrer and a constant pressure funnel.

[0072] Under the protection of nitrogen, the mixed solution was heated to 195° C., and 6.6 g (0.075 mol) of ethylene carbonate was started to be added dropwise at a constant speed. After 1 hour, the result of sampling and measuring the nuclear magnetic phosphorus spectrum showed that the crude yield of the product was only 1.8%, and the reaction was completed at this speed. 40 hours or more.

[0073] Therefore, add 0.34g (0.0023mol) sodium iodide to the 4.5g ethylene carbonate that has not been added dropwise and continue to drop after mixing uniformly, dropwise in 1.5 hours, and continue to insulate for 2.5 hours to comple...

Embodiment 2

[0078] Example 2 Preparation of DOPO Bridged Derivatives of Formula (V) [6H-Dibenzo[c,e][1,2]Oxophosphoglyceride, 6,6'-(1,2-Ethylenediyl) bis-,6,6'-dioxide]

[0079] DOPO32.4g (0.15mol), 25g diphenylmethane and 20g xylene were added to a four-neck flask equipped with a thermometer, a water separator, a mechanical stirrer and a constant pressure funnel.

[0080] Under nitrogen protection, the mixed solution was heated to 195° C., and a mixed solution of 0.34 g (0.0023 mol) sodium iodide and 6.6 g (0.075 mol) ethylene carbonate was added dropwise, and the dropwise addition was completed within 2.5 hours. A large amount of gas was generated from the bubbler of the tail gas, the reflux of the reaction system was not serious, and the reaction temperature was kept stably at 195°C. After 2 hours of incubation, the reaction was terminated.

[0081] After cooling, add 38g of isopropanol and stir under reflux for 20 minutes, the system is white and turbid. After cooling, the solid pr...

Embodiment 3

[0082] Example 3 Preparation of DOPO Bridged Derivatives of Formula (V) [6H-Dibenzo[c,e][1,2]Oxophosphoglyceride, 6,6'-(1,2-Ethylenediyl) bis-,6,6'-dioxide]

[0083] DOPO38.9g (0.18mol) and 20g xylene were added to a four-necked flask equipped with a thermometer, a water separator, a mechanical stirrer and a constant pressure funnel.

[0084] Under the protection of nitrogen, the mixed solution was heated to 195°C, and the mixed solution of 0.27g (0.0018mol) sodium iodide and 5.28g (0.06mol) ethylene carbonate was added dropwise, and the dropwise addition was completed within 2 hours, and then the insulation was continued for 2.5 hours. The reaction is over.

[0085] After cooling, add 40g of isopropanol and stir under reflux for 20 minutes, the system is white and turbid. Suction filtration after standing to cool, the solid product was first washed with isopropanol, then washed three times with an appropriate amount of deionized water, and after vacuum drying at 180 ° C, 20.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com