An environmentally friendly waste heat recovery device for waste gas treatment

A waste heat recovery device and waste gas treatment technology, applied in the field of machinery, can solve the problems of limited waste heat absorption capacity of waste gas, waste of water resources, affecting the efficiency of waste heat absorption of waste gas, etc., so as to improve the efficiency of flow, promote uniform distribution, and promote uniformity The effect of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

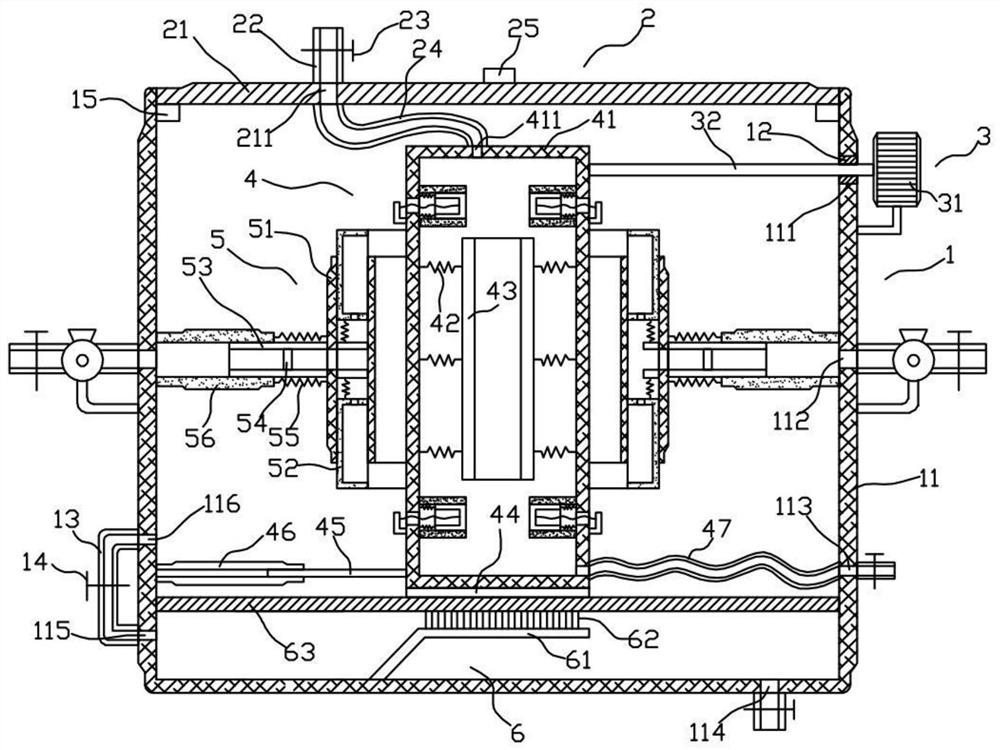

[0017] Such as Figure 1 to Figure 6 As shown, the environmental protection waste heat recovery device for waste gas treatment of the present invention includes a shell structure 1, a closed structure 2 arranged on the shell structure 1, a driving structure 3, a liquid collection structure 4 accommodated in the shell structure 1, and a The gas-collecting structure 5 around the liquid-collecting structure 4 and the heat-conducting structure 6 below the liquid-collecting structure 4 .

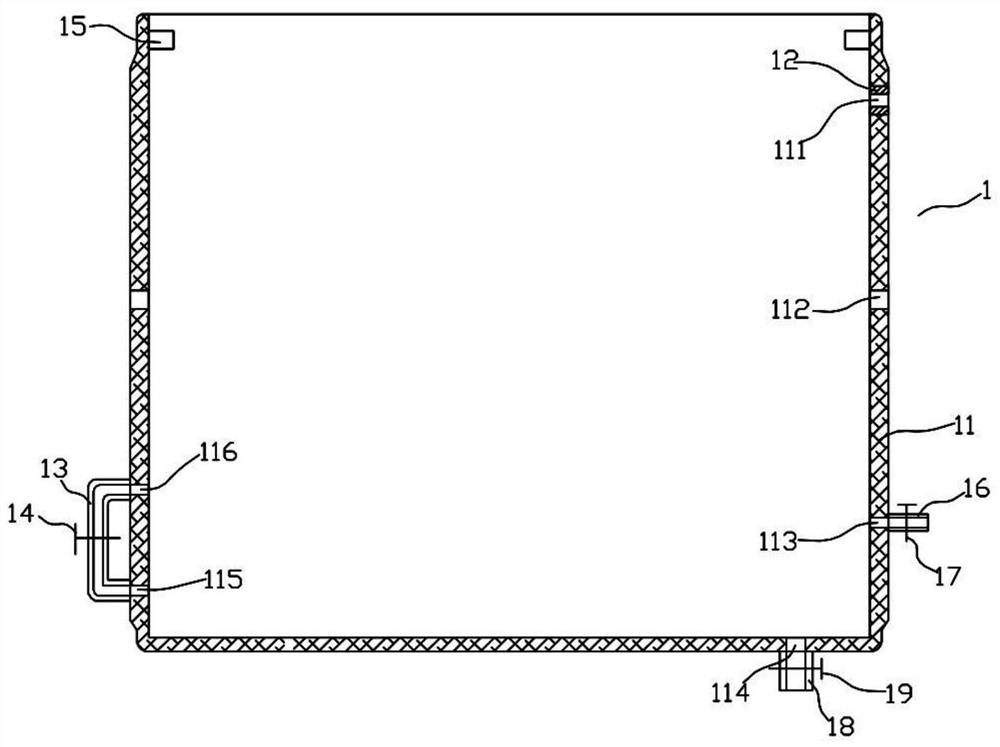

[0018] Such as Figure 1 to Figure 3 As shown, the housing structure 1 includes a housing 11, a sealing block 12 disposed on the housing 11, a connecting pipe 13 disposed outside the housing 11, a first valve 14 disposed on the connecting pipe 13, and a valve housed in the housing. The support blocks 15 on the left and right sides in 11, the liquid outlet pipe 16 located outside the housing 11, the second valve 17 arranged on the liquid outlet pipe 16, the air outlet pipe 18 located below the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com