Combined type environment-friendly package printing device

A packaging printing and combined technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of poor packaging paper processing effect, and achieve the effect of improving printing effect and guaranteeing printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

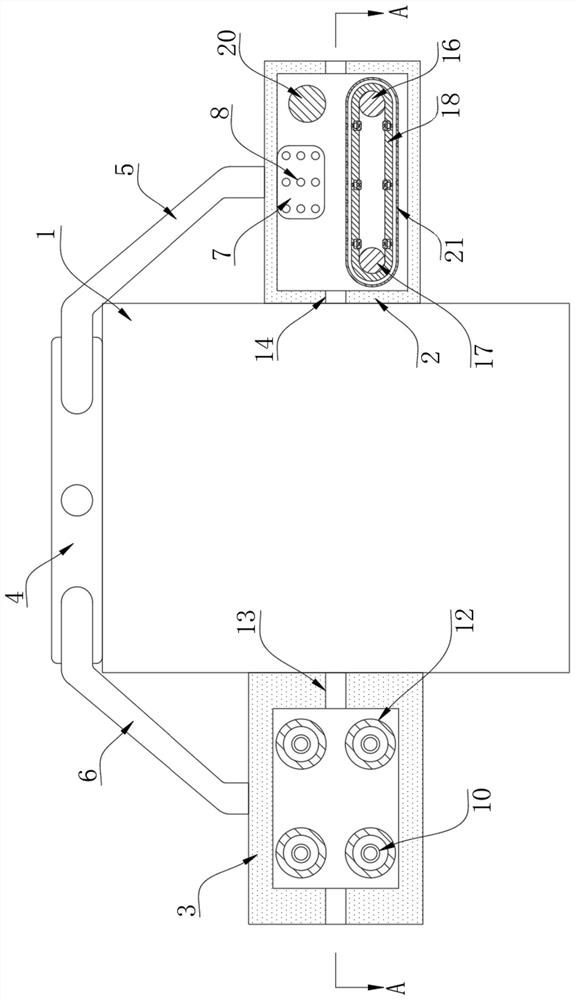

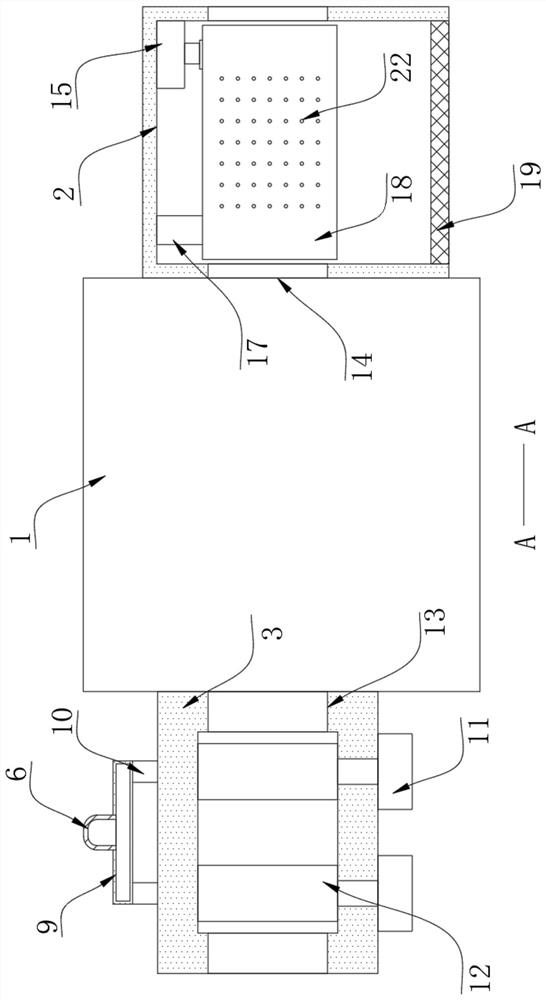

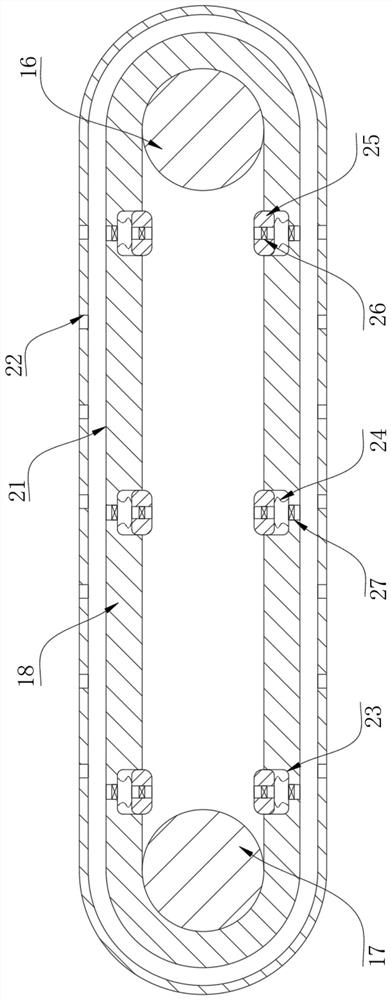

[0019] refer to Figure 1-3 , a combined environment-friendly packaging printing equipment, including a printing box 1 and a discharge box 2 and a feeding box 3 respectively installed on both sides of the printing box 1, a vortex tube 4 is fixed on the top of the printing box 1, and the cooling air of the vortex tube 4 A cold flow tube 5 and a hot flow tube 6 are respectively installed at the outlet and the hot air outlet, and the air inlet of the vortex tube 4 is connected to an external air compressor. The inner wall of the box 2 is fixed with a cold spray box 7, the cold flow pipe 5 runs through the side wall of the discharge box 2 and communicates with the inside of the cold spray box 7, and the side wall of the cold spray box 7 is provided with a plurality of evenly distributed cold spray ports 8 , the side wall of the discharge box 2 runs through and is provided with a feeding trough 14, the inner bottom of the discharge box 2 is provided with a conveying mechanism, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com