Server cabinet with liquid cooling system

A technology for server cabinets and servers, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment construction parts, etc., and can solve the problems of multiple pipeline connections, high leakage risks, pipeline layout, rack design, equipment maintenance and installation Difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

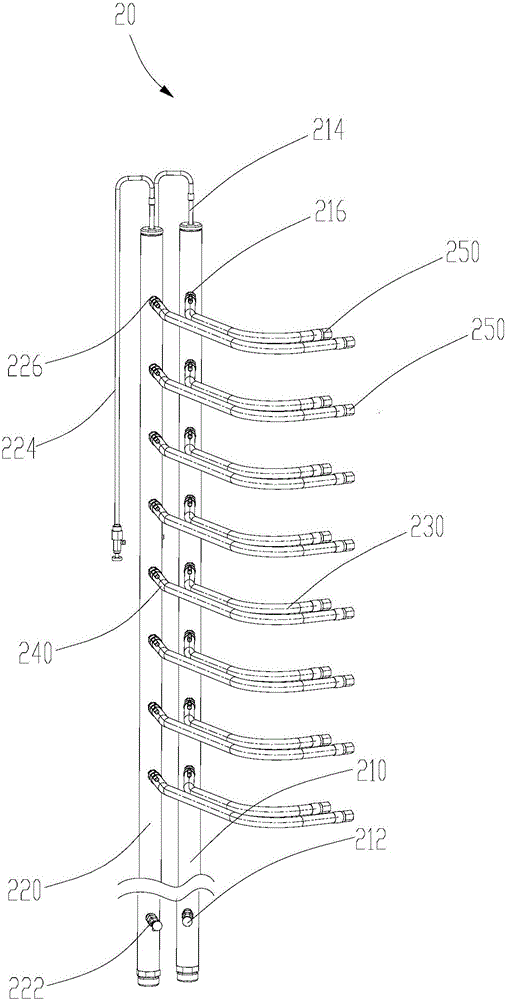

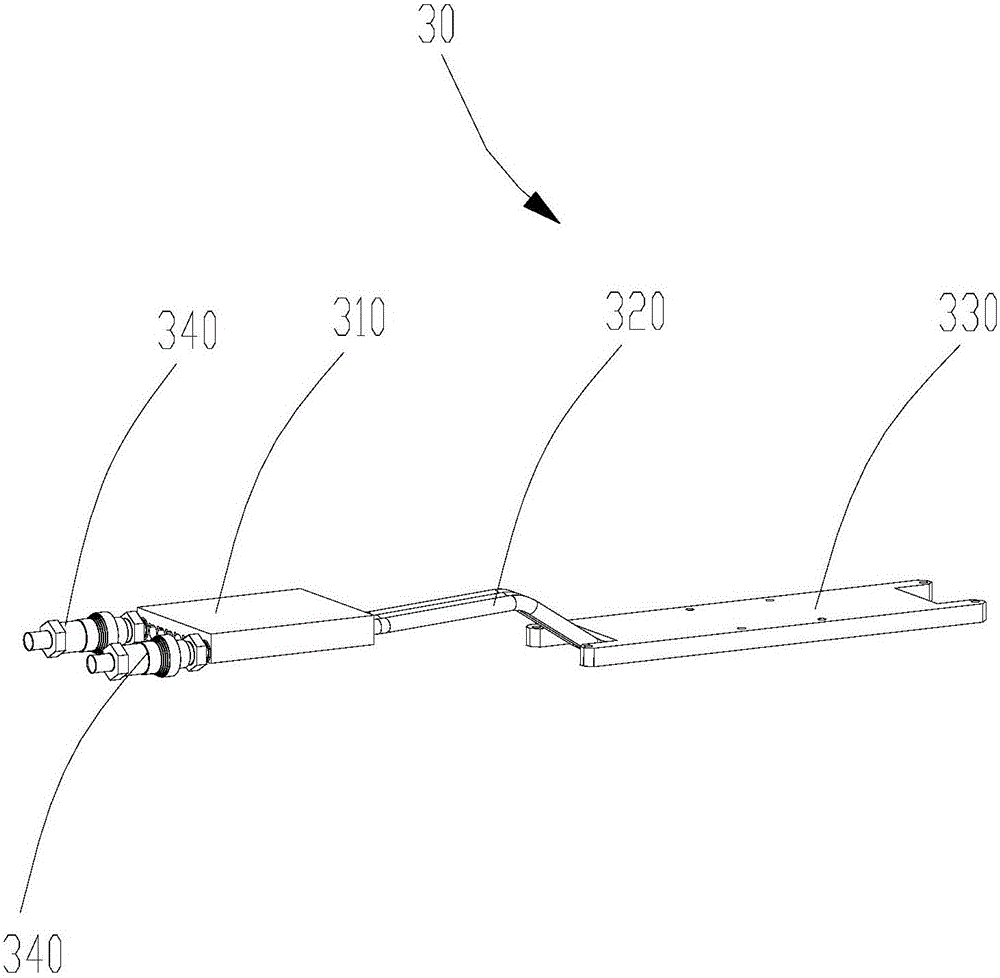

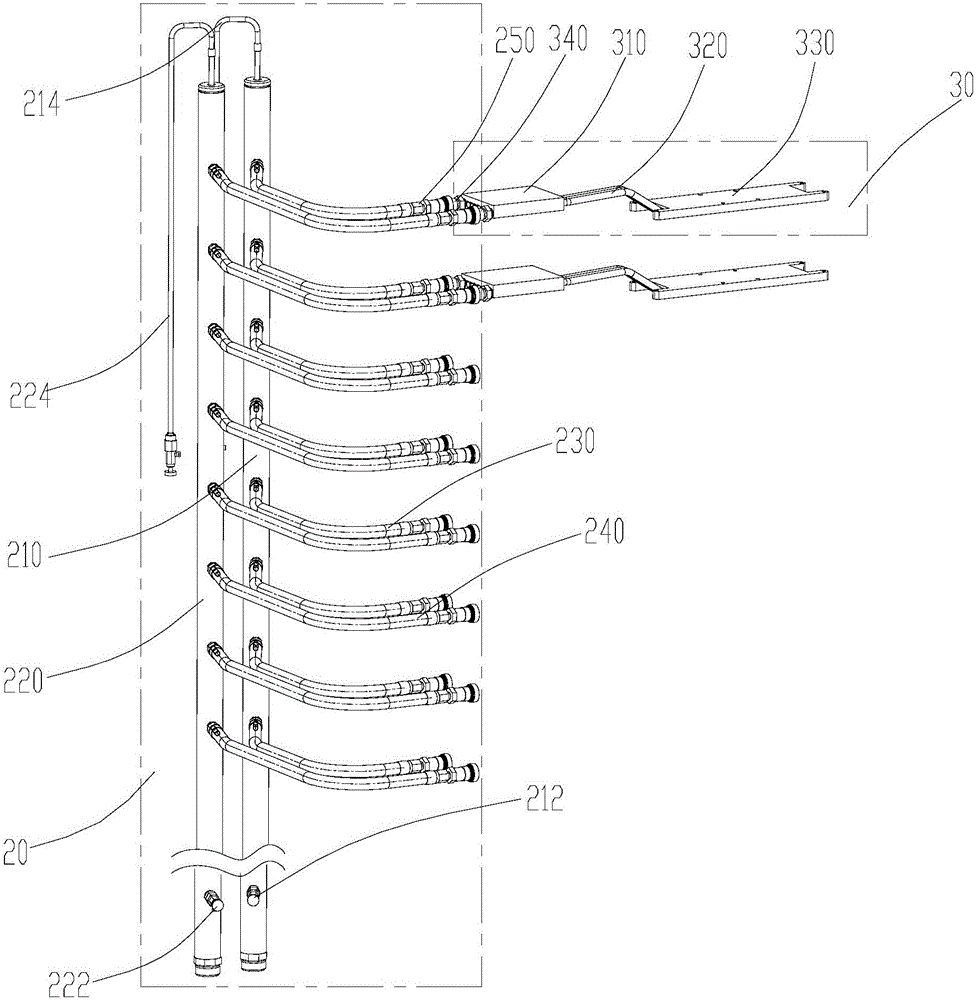

[0027] like Figures 1 to 6 As shown, a server cabinet with a liquid cooling system includes a cabinet body 10, a liquid cooling distribution unit 20, and a heat pipe heat conduction unit 30. The liquid cooling distribution unit 20 includes a liquid inlet pipe 210, a liquid outlet pipe 220, a liquid supply pipe Pipe 230 and liquid return pipe 240, the heat pipe heat conduction unit 30, the heat pipe heat conduction unit 30 includes a liquid cooling module 310, a heat pipe 320, a heat absorption module 330, one end of the liquid supply pipe 230 and the liquid inlet pipe 210 The other end of the liquid supply pipe 230 is connected to the liquid inlet of the liquid cooling module 310, one end of the liquid return pipe 240 is connected to the liquid outlet pipe 220, and the other end of the liquid return pipe 240 It is connected to the liquid outlet of the liquid cooling module 310, one end of the heat pipe 320 is connected to the liquid cooling module 310, and the other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com