Concentration method and special device for sulfuric acid process titanium dioxide solution

A sulfuric acid method, titanium liquid technology, applied in separation methods, chemical instruments and methods, evaporation, etc., can solve the problems of high steam consumption, poor stability of titanium liquid, small scale, etc., to reduce steam consumption, good stability, and energy saving. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

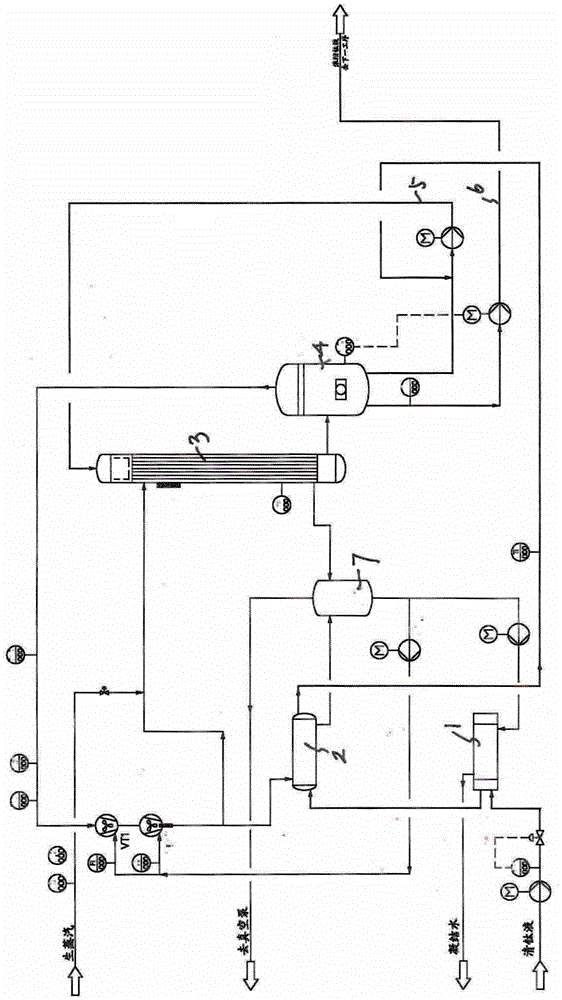

Image

Examples

Embodiment Construction

[0019] A method for concentrating titanium dioxide liquid by sulfuric acid method. The secondary steam generated during the evaporation and concentration process of clear titanium liquid is returned to the evaporation and concentration system after being boosted and heated by a mechanical steam compressor. The evaporation system is kept at -0.08 Operate under MPa.

[0020] The specific steps are:

[0021] The clear titanium liquid passes through the primary preheater and the secondary preheater successively through the pump, preheats to the critical temperature, and then enters the heater tube of the falling film graphite evaporator from the top through the circulating pump, and evenly enters the column of the heating chamber. In the tube, under the action of gravity, the feed liquid descends into a film along the inner wall of the tube, evaporates, and enters the separation chamber of the evaporator at the bottom. A part of the concentrated solution is mixed with the clear t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com