Woven graphene filament electric heating cloth

A technology of graphene and electric heating cloth, applied in the direction of electric heating devices, ohmic resistance heating, ohmic resistance heating parts, etc., can solve the problems of uneven heating, poor rubbing resistance, short service life, etc., to ensure insulation and waterproof performance, Good resistance to bending or flexing, good mechanical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the structure and function of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

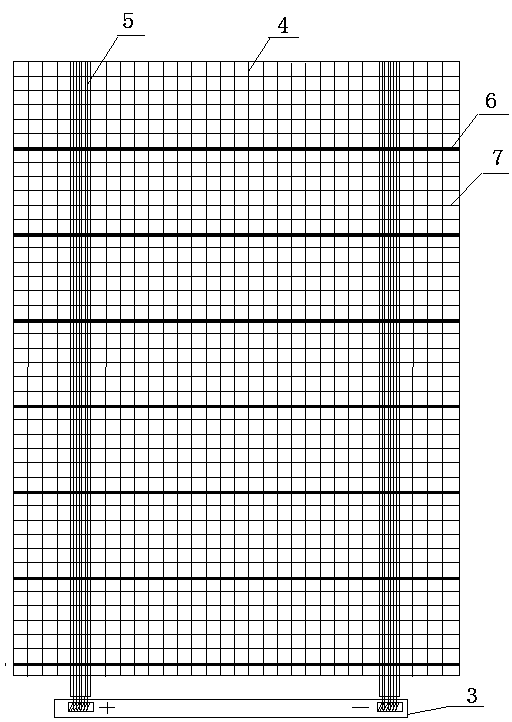

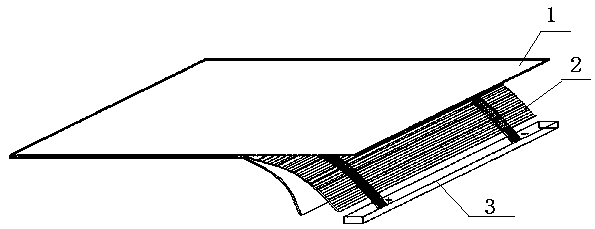

[0024] See attached Figure 1-2 , woven graphene filament electric heating cloth, including two layers of insulating layers 1 and heating cloth 2 between the insulating layers 1; the heating cloth 2 is a woven structure in which warp and weft are interwoven, and the warp is polyester warp Silk 4 and conductive fiber filament 5, the weft thread is graphene filament 6 and polyester weft thread filament 7; the two sides of the width of the heating cloth 2 are respectively woven with some conductive fiber filament 5 warp threads, and other warp threads are polyester warp thread filaments 4. A number of conductive fiber filaments 5 on both sides are warped to form conductive belts on both sides. The polyest...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com