A kind of method of producing cyclopentene by dicyclopentadiene

A technology of dicyclopentadiene and cyclopentene, which is applied in the field of preparation of cyclopentene to achieve high yield, improve distillation efficiency, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

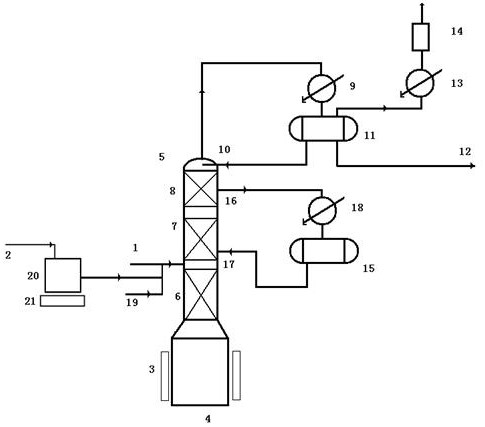

[0081] The specifications of the catalytic distillation tower are: the tower column is 32mm in Ф, the column length is 1000mm, the volume of the tower kettle is 1000mL, and the whole tower body is made of stainless steel. A separation filler and a hydrogenation catalyst are loaded in the column of the catalytic rectification tower. Specifically: (1) Take 200mL of Φ3mm stainless steel wire mesh Φ ring separation packing and install it in the upper half of the column of the catalytic distillation tower; (2) Take 200mL of Pd / Al 2 o 3 Catalyst, installed in the middle section of the column of the catalytic rectification tower; (3) Take 200mL of Φ3mm stainless steel wire mesh Φ ring separation packing, and install it in the lower section of the column of the catalytic rectification tower. The raw material hydrogen is directly sent to the bottom of the catalyst bed without preheating; the raw material dicyclopentadiene is sent to the raw material heater for heating, and then enters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com