Battery pack heat dissipation device and battery system

A heat dissipation device and battery pack technology, applied to battery pack components, secondary batteries, circuits, etc., can solve problems such as reduced battery life, untimely heat dissipation, battery impact, etc., to achieve faster efficiency, temperature balance, and safety high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

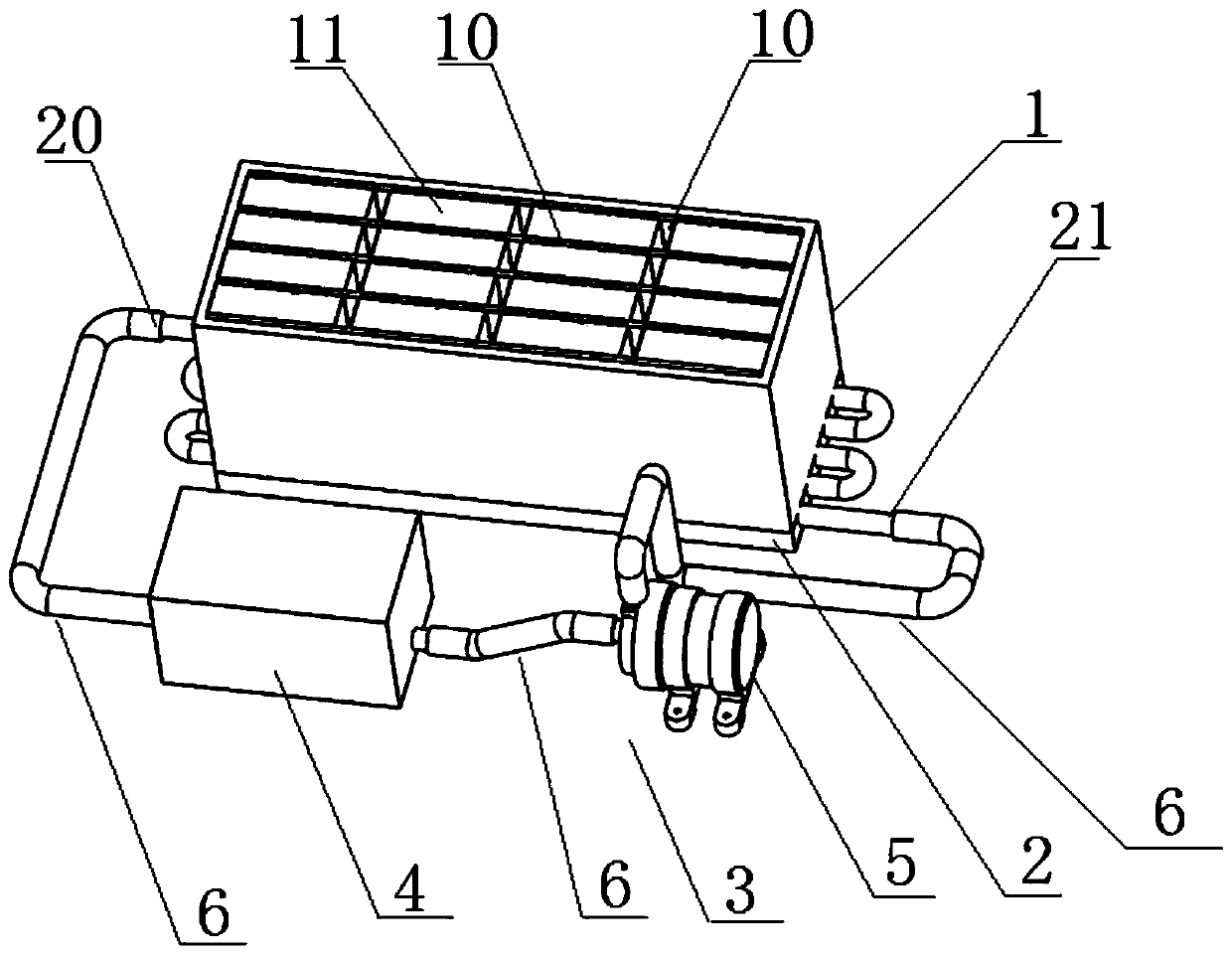

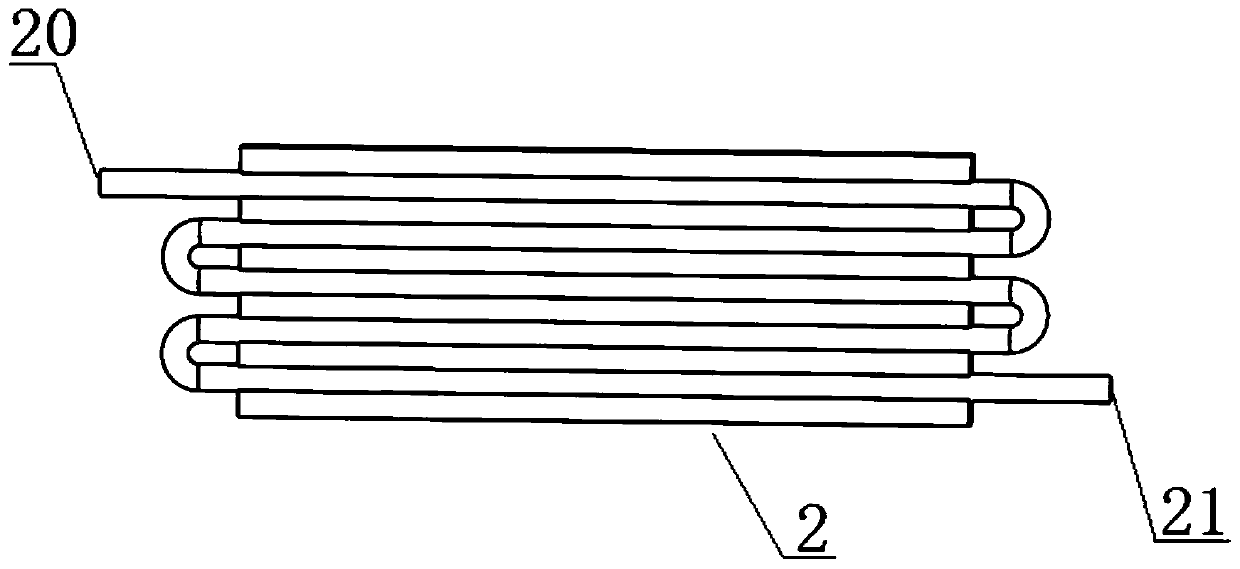

[0026] Such as figure 1As shown, it is a heat dissipation device for a battery pack, including a liquid cooling plate 2, a water circulation system 3, and a box 1 for placing a battery pack. The liquid cooling plate 2 is installed at the bottom of the box 1, and the water circulation One end of the system 3 is connected to the water inlet 21 of the liquid cooling plate 2 , and the other end is connected to the water outlet 20 of the liquid cooling plate 2 . The water circulation system 3 includes a water pump 5, a water tank 4 and a conduit 6. One end of the water tank 4 is connected to the water outlet 20 of the liquid cooling plate 2 through the conduit 6, and the other end is connected to the water inlet of the water pump 5 through the conduit 6. The water outlet end of the water pump 5 is connected to the water inlet 21 of the liquid cooling plate 2 through the conduit 6 . The water outlet 20 of the liquid cold plate 2 is provided with a temperature sensor, and the temper...

Embodiment 2

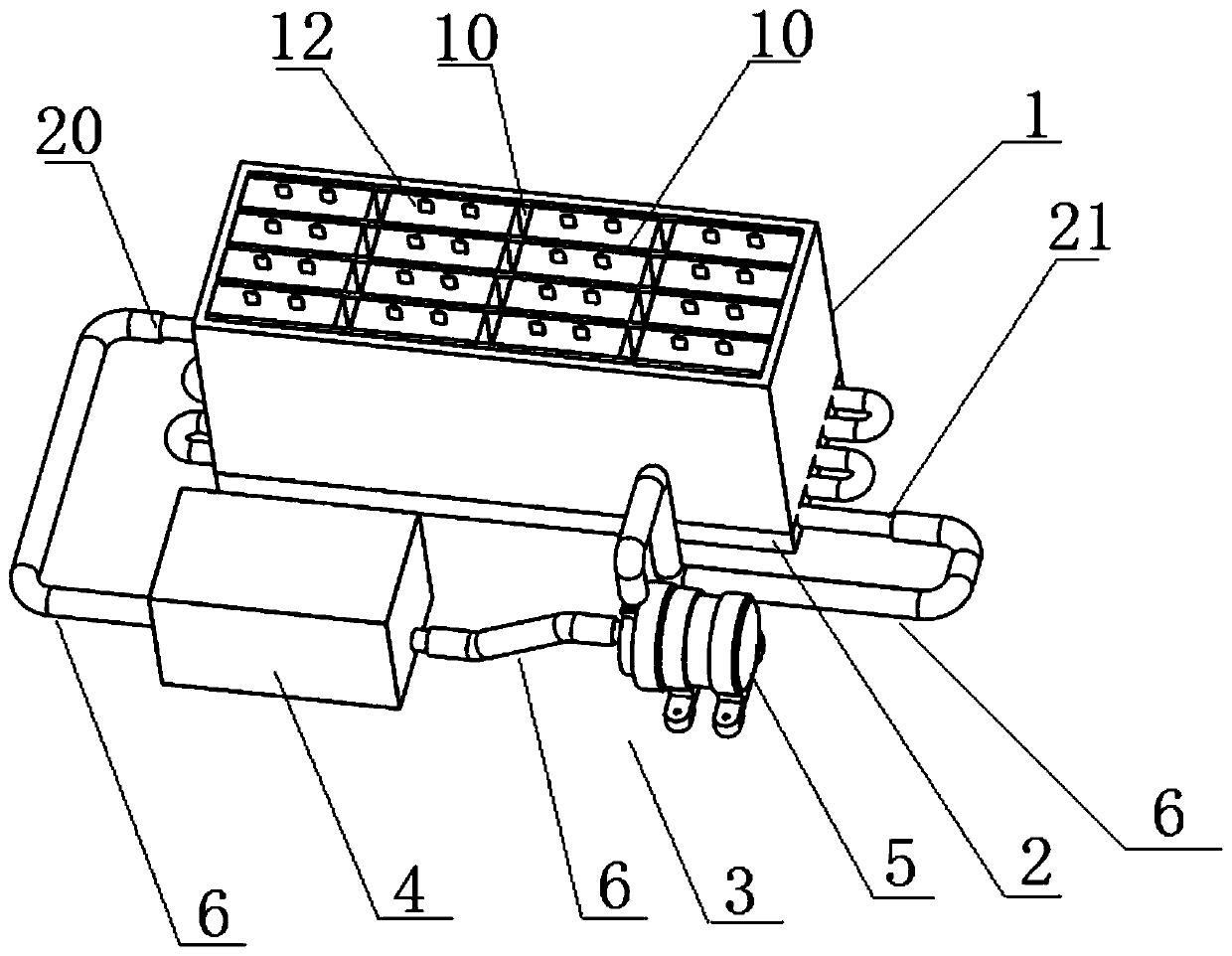

[0032] This embodiment provides a battery system, such as figure 2 As shown, including the lithium battery pack 12 and the battery pack cooling device provided in Embodiment 1, the lithium battery pack 12 is placed in the box body 1; each single battery in the lithium battery pack 12 is evenly installed in the battery placement groove of the box body 1 11, and reasonably connected, there is also a partition 10 between the battery and the outer wall of the casing 1 to separate. Combining the heat sink for the battery pack in Embodiment 1 with the battery pack forms a battery system that can be used. The battery system has high stability and is suitable for electric vehicles or electric motorcycles. Lithium battery 12 is a good rechargeable and dischargeable battery with high stability and long service life, and it has better effect when used in this battery system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com