Method for preparing high-purity cyclopentadiene from dicyclopentadiene

A technology of dicyclopentadiene and cyclopentadiene, which is applied in the field of preparation of cyclopentadiene and cyclopentadiene by thermal cracking of dicyclopentadiene, can solve the problems of small temperature difference, coking, etc., and achieve improved distillation Efficiency, high yield, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

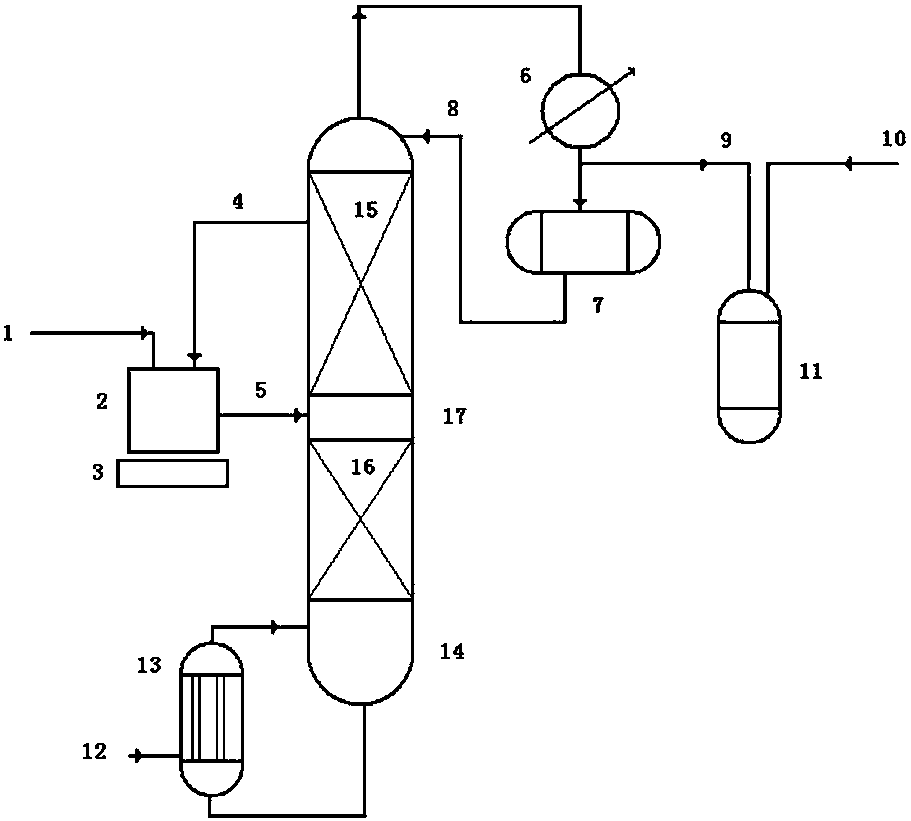

Method used

Image

Examples

Embodiment 1

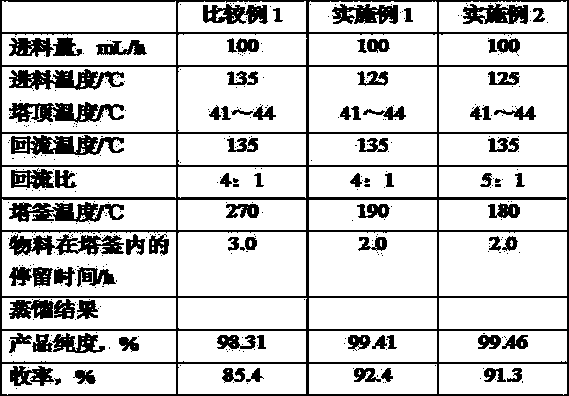

[0069] The rectification tower, operation method and raw materials used in the experiment are the same as those in Comparative Example 1. The difference is that a certain amount of refined naphtha-1 is added in advance to the feed heater 2 and the tower kettle 14. The main physical properties are shown in Table 3. The specific operating conditions and product analysis results of the tower are shown in Table 4.

[0070] From the comparison of the data of Comparative Example 1 and Example 1 in Table 4, it can be seen that the use of refined naphtha-1 as the heating carrier increases the purity of the product from 98.31% to 99.41%; the increase in product yield is more obvious, from 85.4 % Increased to 92.4%. It shows that using refined naphtha-1 as the heating carrier, the heating is more uniform, and there is no local overheating and hot spots.

[0071] In addition, using refined naphtha-1 as a heating carrier can also shorten the residence time of the material in the tower, from ...

Embodiment 2

[0073] The rectification tower, operation method and raw materials used in the experiment are the same as those in Comparative Example 1. The difference is that a certain amount of refined naphtha-2 is added to the feed heater 2 and the tower kettle 14, and the main physical properties are shown in Table 3. The specific operating conditions and product analysis results of the tower are shown in Table 4.

[0074] From the comparison of the data of Comparative Example 1 and Example 2 in Table 4, it can be seen that the purity of the product is increased from 98.31% to 99.32% due to the use of refined naphtha-2 as the heating carrier; the product yield has increased more significantly, from 85.4% Increased to 91.4%. It shows that the refined naphtha-2 is used as the heating carrier, and the heating is even, without local overheating and hot spots.

[0075] In addition, refined naphtha-2 as a heating carrier can also shorten the residence time of the material in the tower, from 3.0h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com