A water-cooled resistor for frequency conversion cabinet and its manufacturing method

A technology of water-cooled resistors and manufacturing methods, applied in the direction of resistors, resistor parts, non-adjustable metal resistors, etc., can solve problems such as poor water flow, inconvenient installation, local temperature rise, etc., and achieve consistent cooling water flow , Simple and convenient installation, enhanced cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

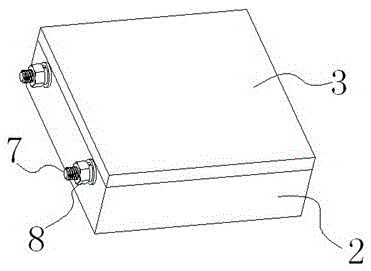

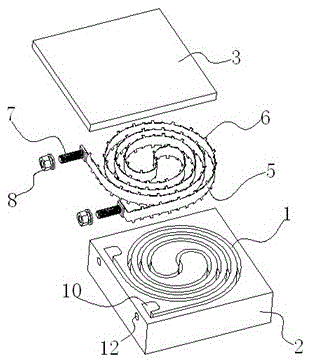

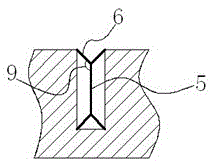

[0026] Example: such as figure 1 , figure 2 with Figure 4 As shown, a water-cooled resistor for a frequency conversion cabinet includes an insulator 2 with a channel 1 inside, an insulating cover 3 arranged on the insulator 2, a resistance band arranged in the insulator channel 1, and the The lead end connected to the two ends of the resistance band, the lead end is located at the two ends 10 of the insulator channel, it is arranged on one side of the insulator 2 and passes through the insulator 2, and the insulator 2 is also provided There are two nozzles 4 respectively connected to the two ends 10 of the insulator channel, and the resistance band includes a strip-shaped resistance band body 5 that is vertically engaged in the insulator channel 1 and is arranged on the resistance band body. 5, a plurality of protruding pieces 6 on the upper and lower sides, the resistance band body 5 and the protruding pieces 6 are integrated, and the adjacent protruding pieces 6 on each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com