Composite aerogel thermal insulation coating and preparation method thereof

A technology for thermal insulation coatings and aerogels, applied in fire-resistant coatings, reflective/signal coatings, alkali metal silicate coatings, etc. Insufficient dispersion effect of silica aerogel, etc., to achieve the effect of good environmental protection grade, good water resistance and good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

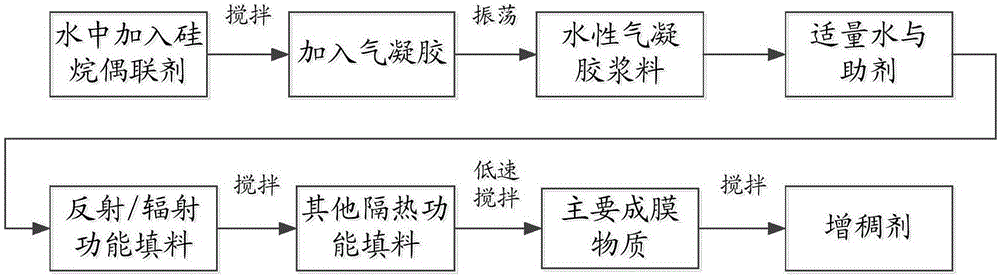

[0043] Such as figure 1 Shown, a kind of preparation method of airgel composite thermal insulation coating, the step of this method comprises:

[0044](1) Add 15g of KH570 silane coupling agent and 1g of X-405 wetting agent into 100g of water, and stir for 30s at a stirring rate of 400 rpm;

[0045] (2) adding 30 g of silica airgel as the main filler to the solution obtained in step (1) in small quantities several times, and oscillating with a high-speed oscillator for 30 minutes to obtain a water-based airgel slurry;

[0046] (3) Add 20 g of water, 1 g of Tehaosan 731A dispersant and 1 g of BYK8821 defoamer to the aqueous airgel slurry obtained in step (2);

[0047] (4) Add 5 g of high white aluminum silicate and 10 g of titanium dioxide to the product obtained in step (3), and stir for 5 min at a stirring rate of 500 to 700 rpm;

[0048] (5) Add 15g of ceramic microbeads, 60g of water glass and 60g of silicon acrylic emulsion to the product obtained in step (4), and stir f...

Embodiment 2

[0052] A preparation method of an airgel composite thermal insulation coating, the steps of the method comprising:

[0053] (1) Add 20g of KH570 silane coupling agent and 1g of X-405 wetting agent into 120g of water, and stir for 30s at a stirring speed of 400 rpm;

[0054] (2) adding 40g of silica airgel as the main filler into the solution obtained in step (1) in small quantities several times, and using a high-speed oscillator to vibrate for 30 minutes to obtain an aqueous airgel slurry;

[0055] (3) Add 1g Tehaosan 731A dispersant and 1g BYK8821 defoamer to the aqueous airgel slurry obtained in step (2);

[0056] (4) Add 15g of zinc oxide to the product obtained in step (3), and stir for 15min at a stirring rate of 500 to 700 rpm;

[0057] (5) Add 5g of closed-cell perlite microbeads, 90g of water glass and 30g of silicon acrylic emulsion to the product obtained in step (4), and stir for 10min at a stirring rate of 200 to 300 rpm;

[0058] (6) Add 0.5g of 2020 thickener ...

Embodiment 3

[0061] A preparation method of an airgel composite thermal insulation coating, the steps of the method comprising:

[0062] (1) Add 15g of KH570 silane coupling agent and 1g of X-405 wetting agent into 100g of water, and stir for 30s at a stirring rate of 400 rpm;

[0063] (2) adding 30 g of silica airgel as the main filler to the solution obtained in step (1) in small quantities several times, and oscillating with a high-speed oscillator for 30 minutes to obtain a water-based airgel slurry;

[0064] (3) Add 20 g of water, 1 g of Tehaosan 731A dispersant and 1 g of BYK8821 defoamer to the aqueous airgel slurry obtained in step (2);

[0065] (4) Add 15 g of high-white aluminum silicate to the product obtained in step (3), and stir for 10 minutes at a stirring rate of 500 to 700 rpm;

[0066] (5) Add 15g of ceramic microbeads, 30g of water glass and 90g of silicon acrylic emulsion to the product obtained in step (4), and stir for 20min at a stirring rate of 200 to 300 rpm;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com