Method and apparatus for esterifying fatty acid

A free fatty acid, esterification technology, applied in the field of esterified fatty acid, can solve the problems of difficult design, expensive stainless steel, high corrosiveness and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

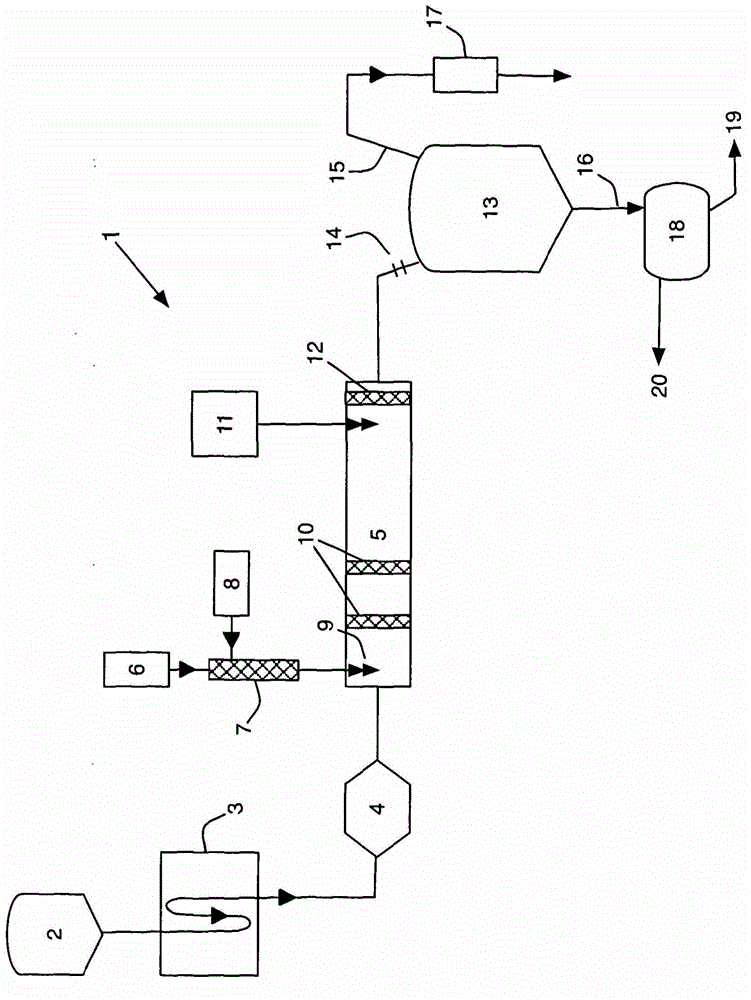

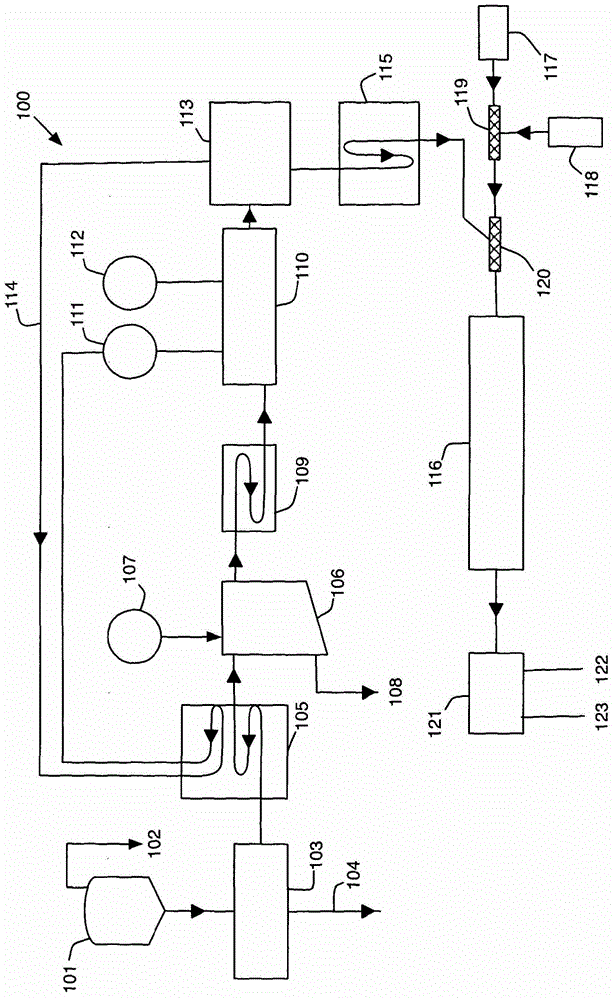

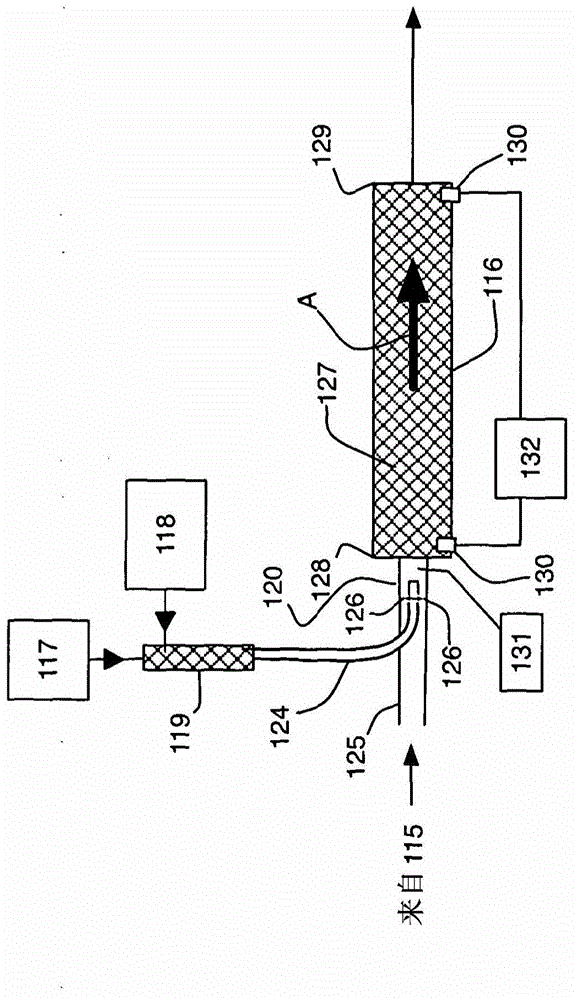

[0120] figure 1 is a schematic diagram of an apparatus 1 for esterification of free fatty acids in natural oils and fats. Components are shown schematically and not to scale. Details such as pumps, valves etc. are not shown unless they are required therein to understand the invention. Those skilled in the art will be able to include conventional valves and pumps based on their common knowledge.

[0121] The device 1 comprises a tank 2 for storing natural oils, such as sunflower oil. The natural oil is fed into heater 3 where its temperature is raised to about 150°C. The pump 4 is configured to feed the heated natural oil into the tubular reactor 5 . The pump 4 can be any conventional pump and need not be made of acid resistant material as no acid mixes with the grease at this stage. The feed of natural oils and fats 2 may comprise natural oils and fats which have been processed in the degumming unit 106, which is hereinafter referred to as natural oils or fats obtained by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com