Method for preparing biodiesel by taking pupal oil as production raw material

A technology of biodiesel and silkworm chrysalis oil, which is applied in the direction of fat oil/fat production, biofuel, fat production, etc., can solve the problems of transportation and refining cost constraints, source and cost constraints, and limited quantity, so as to broaden the sources of raw materials, Large economic value and social significance, the effect of reducing industrial wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

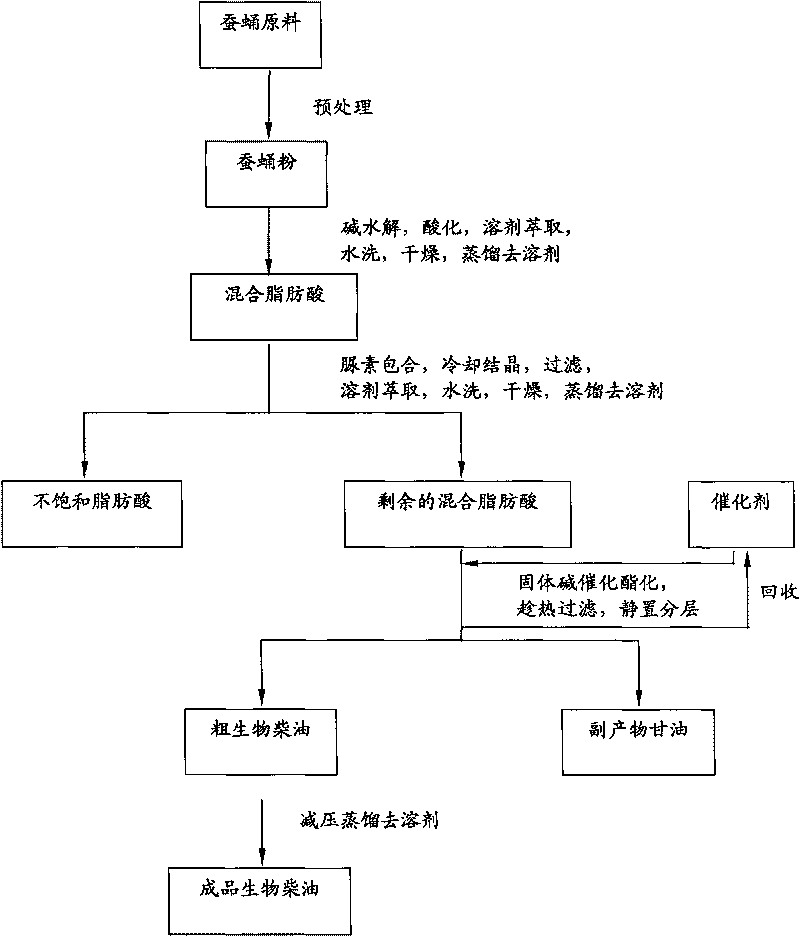

Method used

Image

Examples

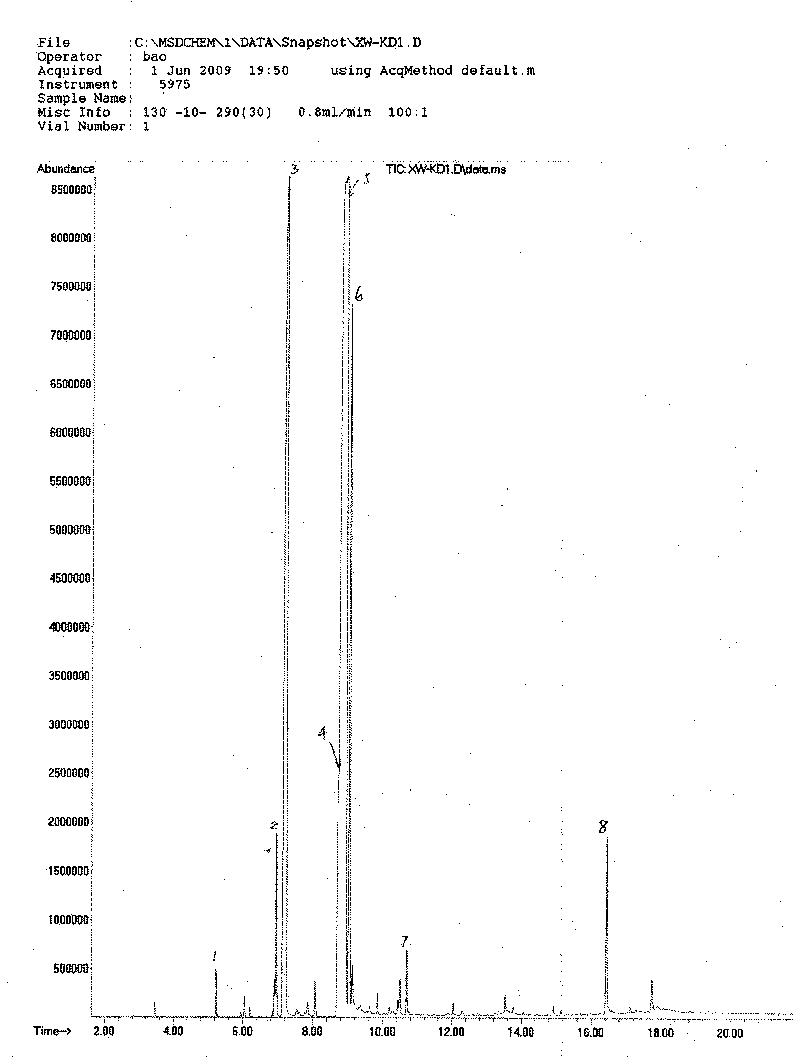

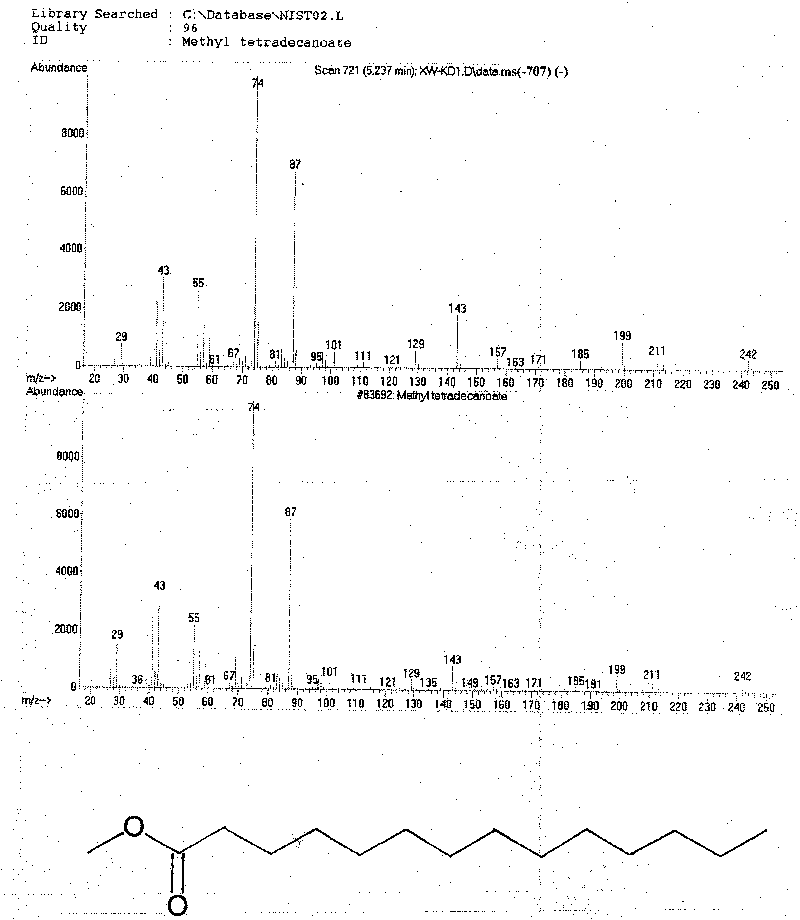

Embodiment 1

[0039] The silkworm chrysalis is removed from dust and impurities, dried, crushed and made into silkworm chrysalis powder. Crude silkworm chrysalis oil was extracted from silkworm chrysalis powder by heating and reflux using petroleum ether. The thick silkworm chrysalis oil of gained is mixed with 1wt% NaOH-95 ethanol solution (solvent is 95 ethanol, and the mass concentration of solute sodium hydroxide in solution is 1%, meaning is the same in the following examples), under 30 ℃ of water baths Stir and saponify for 3h, cool to room temperature, add petroleum ether to extract and remove unsaponifiable matter. Add 5wt% HCl solution to the saponification solution to acidify to pH=3-4 to obtain free fatty acid. Extract fatty acid with petroleum ether, let stand to separate layers, combine petroleum ether layer, wash to neutrality, dry, filter, recover petroleum ether, obtain mixed fatty acid, yield rate is 34.7%; Mix the methanol saturated solution of fatty acid and urea Stir a...

Embodiment 2

[0041] The silkworm chrysalis is removed from dust and impurities, dried, crushed and made into silkworm chrysalis powder. Crude silkworm chrysalis oil was extracted from silkworm chrysalis powder by heating and reflux using n-hexane. The obtained crude silkworm chrysalis oil was mixed with 10 wt% NaOH-95 ethanol solution, stirred and saponified in a water bath at 90°C for 12 hours, cooled to room temperature, and extracted with n-hexane to remove unsaponifiable matter. Add 20wt% HCl solution to the saponification solution to acidify to pH=3-4 to obtain free fatty acid. Extract fatty acid with n-hexane, let stand to separate layers, combine n-hexane layer, wash to neutrality, dry, filter, recover n-hexane to obtain mixed fatty acid with a yield of 46.3%; The solution is stirred and mixed according to the volume ratio of 1:1, clathrate at 20°C for 1 hour, the clathrate is cooled and crystallized, filtered, the obtained filtrate is extracted with n-hexane, washed with water and...

Embodiment 3

[0043] The silkworm chrysalis is removed from dust and impurities, dried, crushed and made into silkworm chrysalis powder. Crude silkworm chrysalis oil was extracted from silkworm chrysalis powder by heating and reflux using petroleum ether. The obtained crude silkworm chrysalis oil was mixed with 4wt% NaOH-95 ethanol solution, stirred and saponified in a water bath at 65° C. for 1 h, cooled to room temperature, and extracted with a small amount of petroleum ether to remove unsaponifiable matter. Add 10% HCl solution to the saponification solution to acidify to pH = 3-4 to obtain free fatty acid. Extract fatty acid with petroleum ether, let stand to separate layers, combine petroleum ether layers, wash with water until neutral, dry, filter, recover petroleum ether, and obtain mixed fatty acid with a yield of 65.0%; the ethanol saturated solution of mixed fatty acid and urea is Stir and mix at a volume ratio of 1:2, clathrate at 4°C for 2 hours, cool and crystallize the clathr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com