Technique for producing fatty acid methyl ester

A technology of fatty acid methyl ester and production process, which is applied in the field of producing high-content fatty acid methyl ester, can solve problems such as low product quality, impact on application range, quality discount of fatty acid methyl ester, etc., and achieve high economic value, high utilization value, and wide application The effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

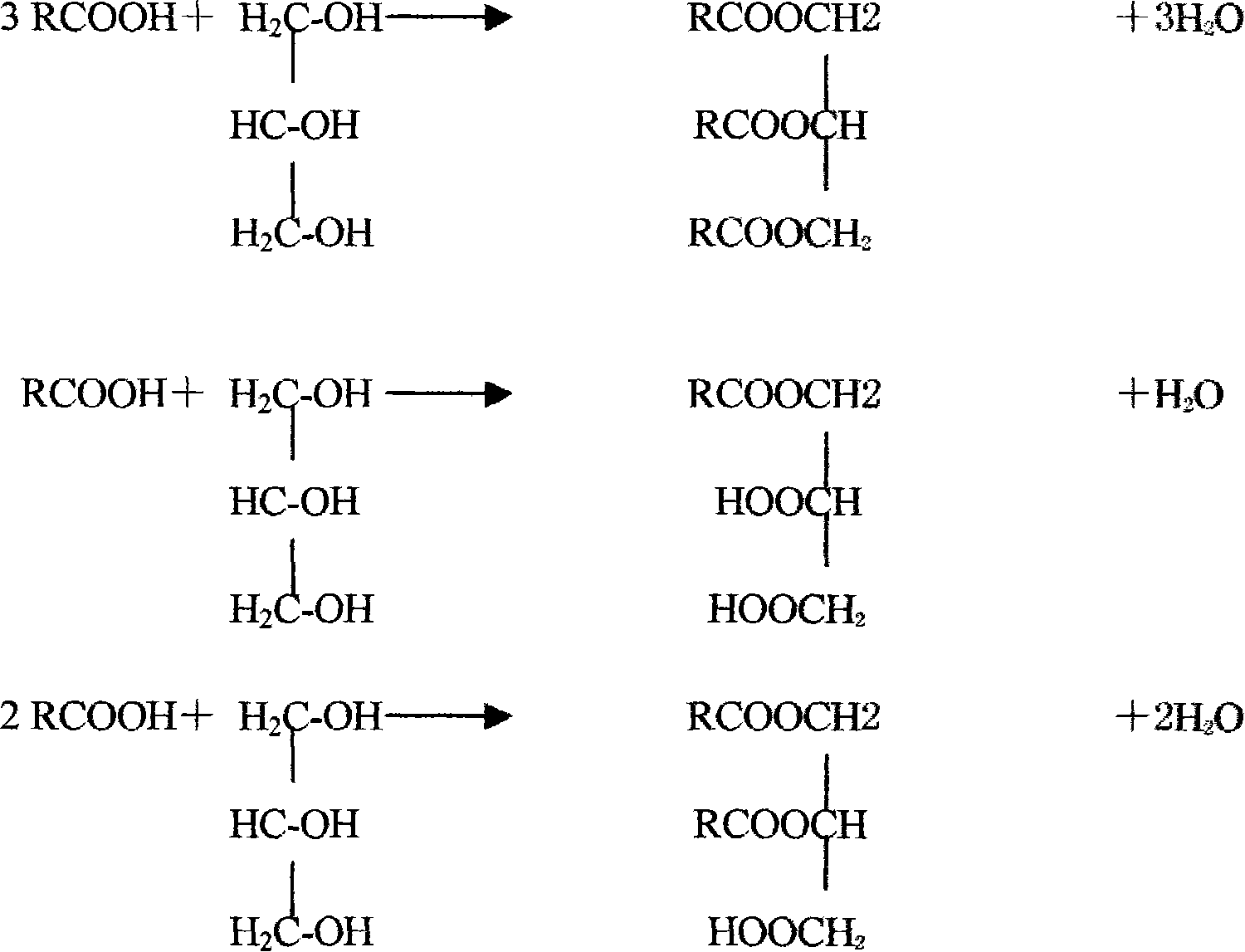

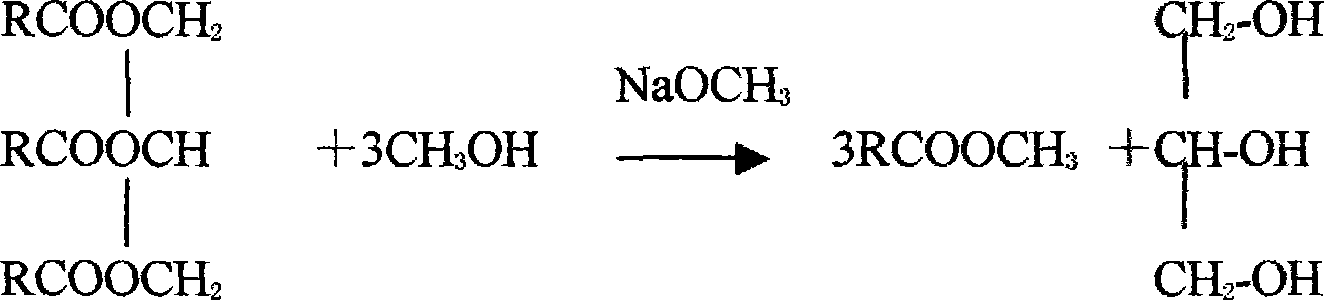

[0012] The production process of fatty acid methyl ester is as follows: add 50% water to dilute the leftovers produced by refining oil, stir evenly and heat to 75°C, sieve to remove impurities to obtain acidified oil or crude fatty acid, take acidified oil or crude fatty acid 100 20 parts, add 20 parts of glycerin and put it in the reaction kettle for reaction, the temperature is controlled in the range of 210-230 °C, the vacuum pressure is 50kpa, the free fatty acid in acidified oil or crude fatty acid reacts with glycerin to form glycerol ester, and the reaction formula is as follows:

[0013]

[0014] The water and gas phase mixture produced by the reaction are separated by vacuum pumping. The unsaponifiable matter in acidified oil or crude fatty acid does not react with glycerin. The boiling points of unsaponifiable matter and glyceride are different, and the boiling point of a small amount of unreacted free fatty acid is lower than that of glyceride. Boiling point, incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com