Method for preparing glycerin from byproduct in manufacture procedure of biodiesel

A biodiesel and by-product technology, applied in the separation/purification of hydroxyl compounds, organic chemistry, etc., can solve the problems of huge investment and low added value of end products, and achieve the effect of economical operation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereby the relevant technical content of the present invention is described as follows with accompanying drawings:

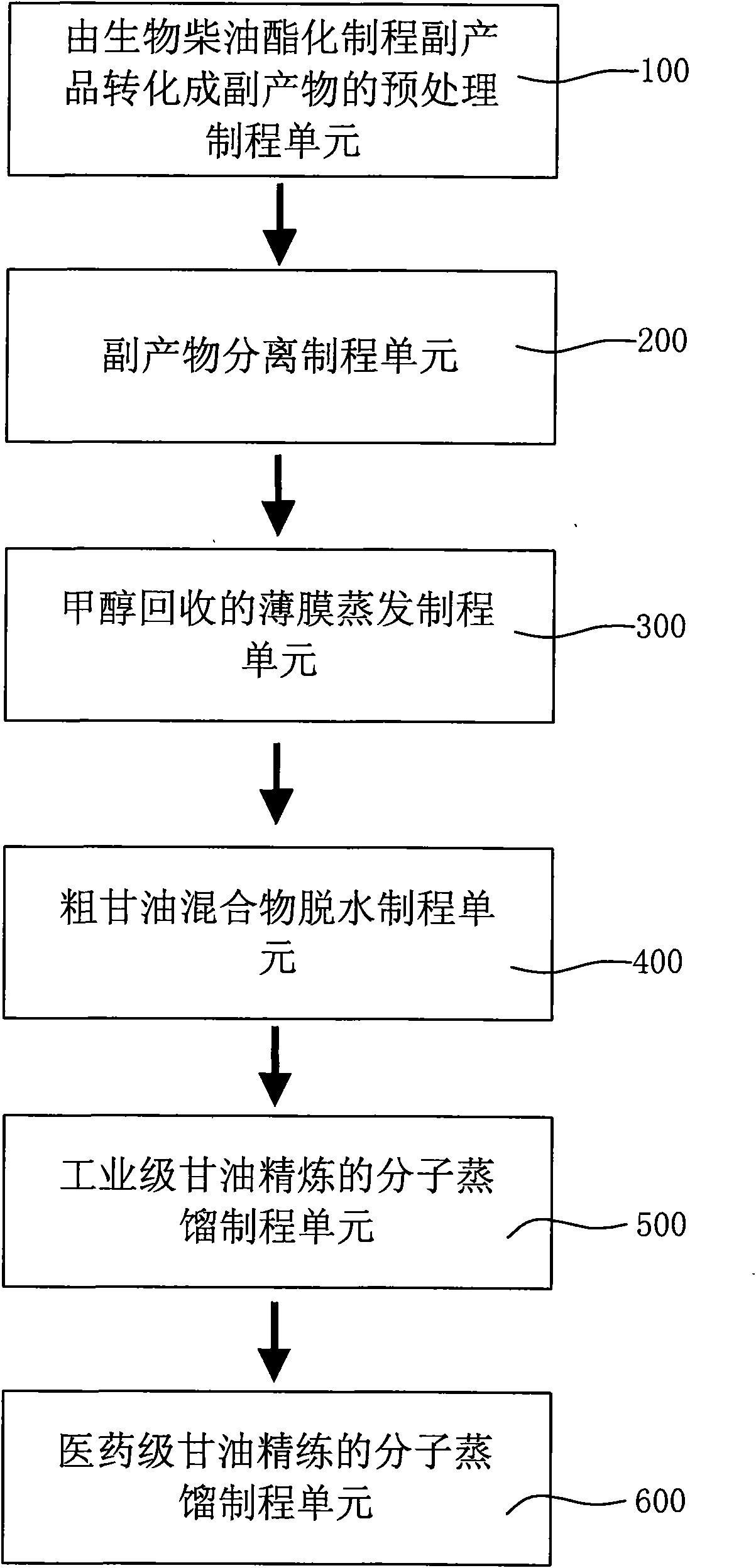

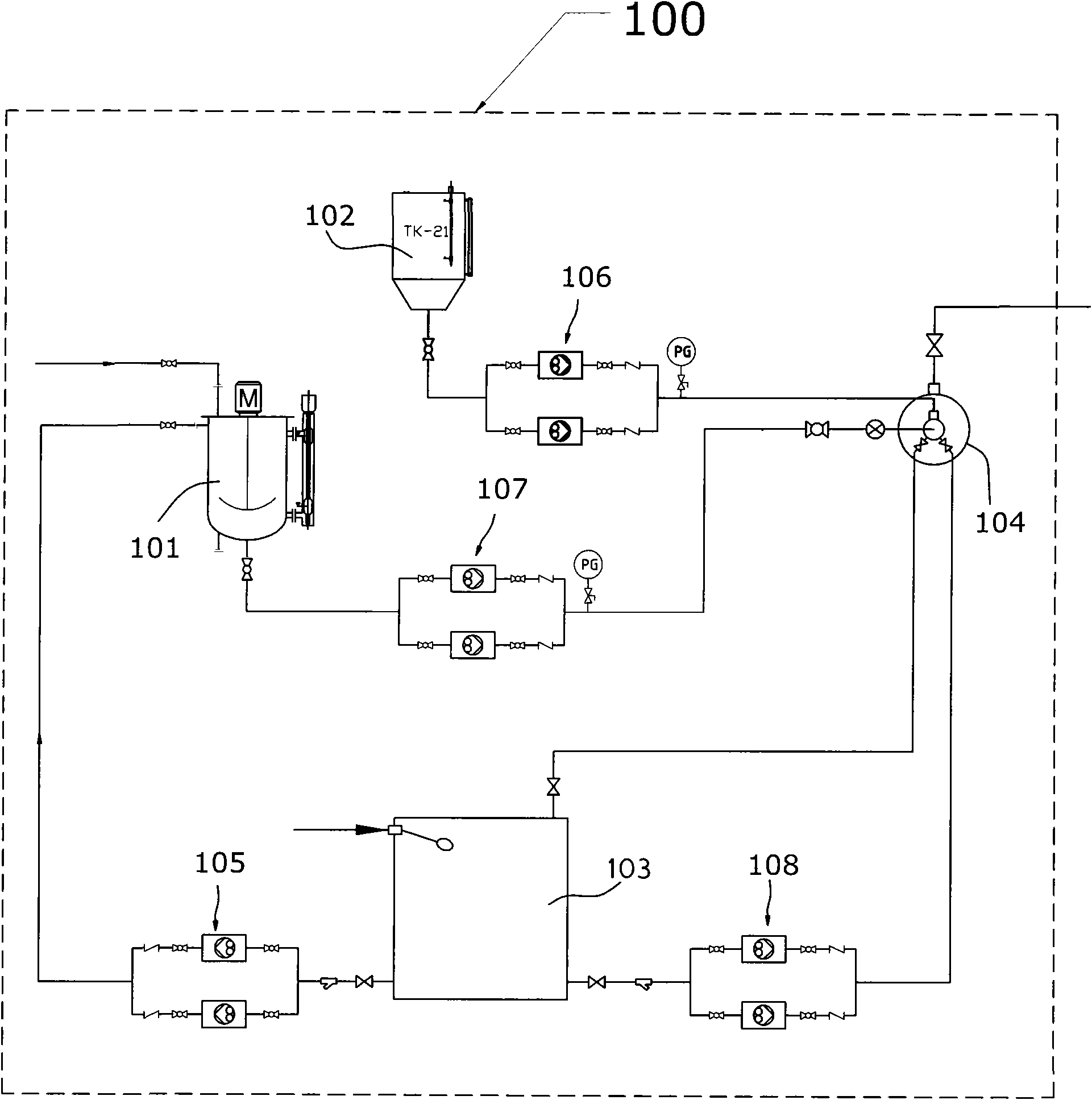

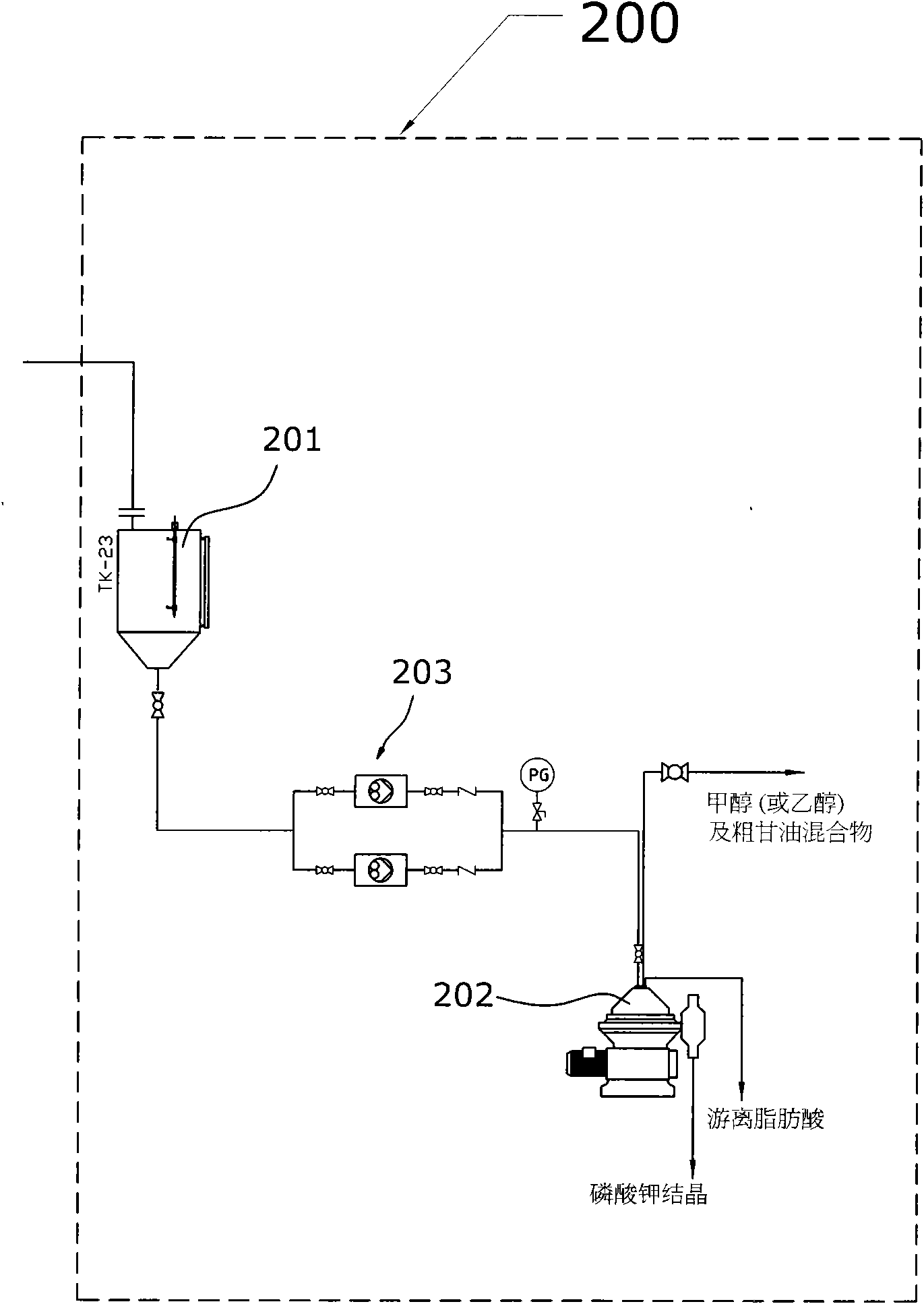

[0036] figure 1 It is a process schematic diagram of the present invention to prepare (pharmaceutical grade) glycerin from the by-product of the biodiesel process. As shown in the figure: the present invention is a method for preparing (pharmaceutical grade) glycerol from the by-products of the biodiesel process, including a process unit 100 for recyclable by-product pretreatment by converting the by-product of the esterification process, and a separation of the by-product Process unit 200, a thin film evaporation process unit 300 for recovering methanol, a crude glycerol mixture dehydration process unit 400, a molecular distillation process unit 500 for industrial-grade glycerin refining, and a molecular distillation process unit 600 for pharmaceutical-grade glycerin refining, for refining , industrial grade and pharmaceutical grade glycerin. The afore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com