Method for extracting fatty acid methyl ester from vegetable pitch

A technology of fatty acid methyl ester and vegetable asphalt, which is applied in the direction of fatty acid esterification, fatty acid production, fatty acid chemical modification, etc., can solve the problems of waste of resources, high rectification temperature, lower yield of fatty acid methyl ester, etc., and achieve low equipment requirements , simple post-processing, reduced reaction temperature and reaction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

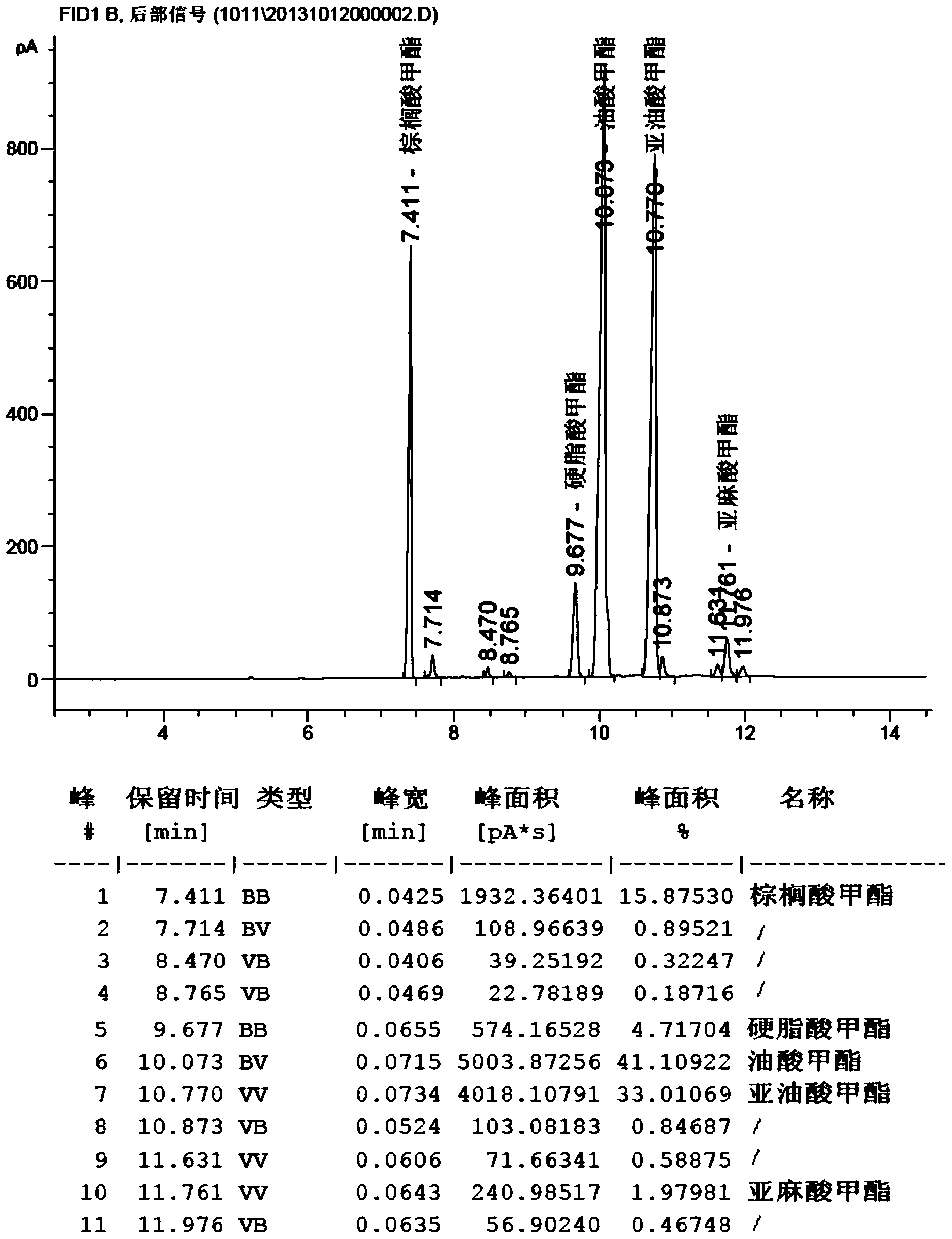

Embodiment 1

[0023] Taking 1000kg of plant asphalt with an acid value of 8mgKOH / g as an example (plant asphalt was purchased from Xinji Jiangyang Chemical Co., Ltd., and the weight percentage of fatty acid or its ester is about 60%), add 5.5kg of concentrated sulfuric acid and 100kg of methanol, Stir and react at 85°C for 30 minutes, then add 100kg of methanol, centrifuge, evaporate the upper liquid, recover methanol, and obtain crude fatty acid methyl ester, separate the lower part for use as asphalt, and obtain crude fatty acid methyl ester acid after evaporating methanol The value is 1.2mgKOH / g, add 2.85kg of 30% liquid caustic soda (NaOH), wash until neutral, vacuum dehydrate, then add decolorizer to decolorize to obtain 576kg of fatty acid methyl ester product, the content of fatty acid methyl ester is 96.5%, and the yield is about 96%. The product prepared in this example was detected by gas chromatography (detection conditions: HP-INNowax chromatographic column, inlet temperature: 2...

Embodiment 2

[0025] Taking 1000kg of plant asphalt with an acid value of 25mgKOH / g as an example (the plant asphalt obtained after the preparation of fatty acid methyl ester by Zhejiang Jiaao Environmental Protection Technology Co., Ltd., the weight percentage of fatty acid or its ester is about 70%), add 25kg Phosphoric acid and 300kg of methanol, stirred and reacted at 70°C for 90 minutes, then added 120kg of methanol, centrifuged, evaporated the upper liquid, recovered methanol, and obtained crude fatty acid methyl ester, separated the lower part and used it as pitch, obtained after evaporating methanol The acid value of crude fatty acid methyl ester is 1.5mgKOH / g, add 1.7kg soda ash (Na 2 CO 3 ), washing to neutrality, vacuum dehydration, and decolorization by adding a decolorizer to obtain 658kg of fatty acid methyl ester product, the content of fatty acid methyl ester is 97.5%, and the yield is about 94%. The gas chromatography detection result is similar to Example 1, mainly contai...

Embodiment 3

[0027] Taking 1000kg of plant asphalt with an acid value of 17mgKOH / g as an example (the plant asphalt obtained after the fatty acid methyl ester was prepared by Zhejiang Jiaao Environmental Protection Technology Co., Ltd., the weight percentage of fatty acid or its ester is about 65%), add 12kg Phosphoric acid, 8kg of sulfuric acid and 250kg of methanol, stirred and reacted at 65°C for 70 minutes, then added 180kg of methanol, centrifuged, evaporated the upper liquid, recovered the methanol, and obtained crude fatty acid methyl ester, separated the lower part for use as asphalt, and evaporated the methanol The thick fatty acid methyl ester acid value that obtains after the end is 1.23mgKOH / g, adds 1.62kg soda ash, washes to neutrality, vacuum dehydration, then adds decolouring agent decolorization to obtain fatty acid methyl ester product 631kg, fatty acid methyl ester content is 94.5%, yield About 97%. The gas chromatography detection result is similar to Example 1, mainly c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com