Mixed fatty acid high performance liquid phase chromatography method and application

A high-performance liquid chromatography and mixed fatty acid technology, which is applied in the direction of material separation, analysis materials, instruments, etc., can solve the problems of high absorbance, low reproducibility, complicated operation, etc., and achieve accurate and reliable results, simple and easy operation, and detection The effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

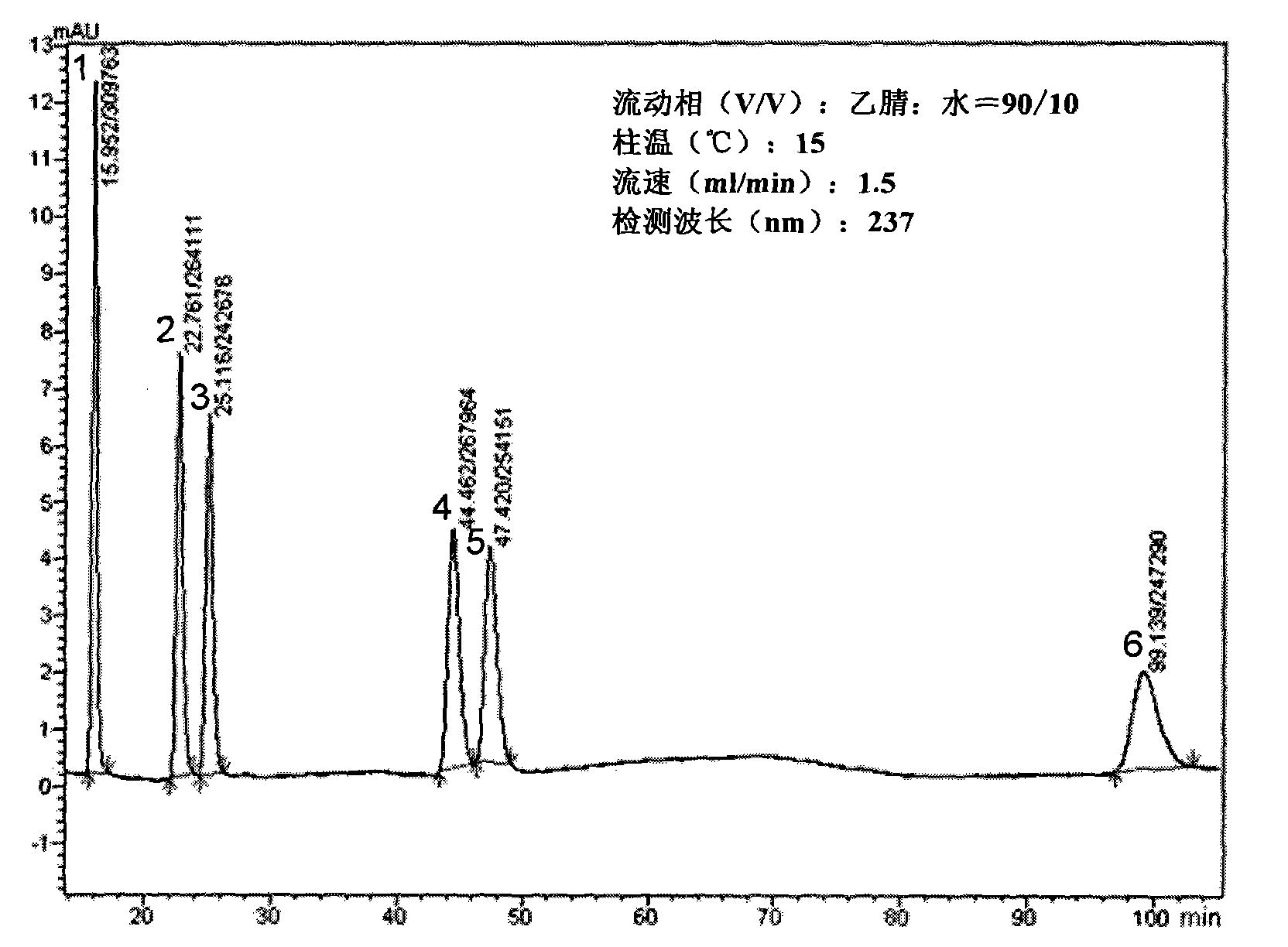

[0027] Mixed fatty acid analysis test.

[0028] 1. Instruments and main reagents

[0029] 1.1 Test equipment

[0030] Chromatographic instrument configuration: high performance liquid chromatography (Shimadzu (SHIMADZU) LC-20AD high performance liquid chromatography, Shimadzu CTO-10AS column thermostat, Shimadzu SPD-M20A diode array detector); record chromatograms (Shimadzu) Jin LC solution chromatography data workstation).

[0031] 1.2 Reagents

[0032] Standards: linolenic acid (C18:3), palmitoleic acid (C16:1), linoleic acid (C18:2), oleic acid (C18:1), palmitic acid (C16:0), and stearic acid ( C18:0) was purchased from Sigma Company of the United States, and the reference grade was obtained.

[0033] 2. Preparation of standard samples

[0034] 6 kinds of fatty acids were formulated into 1 mg / ml fatty acid solutions with methanol as solvent; equal amounts of fatty acid solutions were uniformly mixed to form fatty acid mixed solutions.

[0035] 3. Fatty acid lipidation...

Embodiment 2

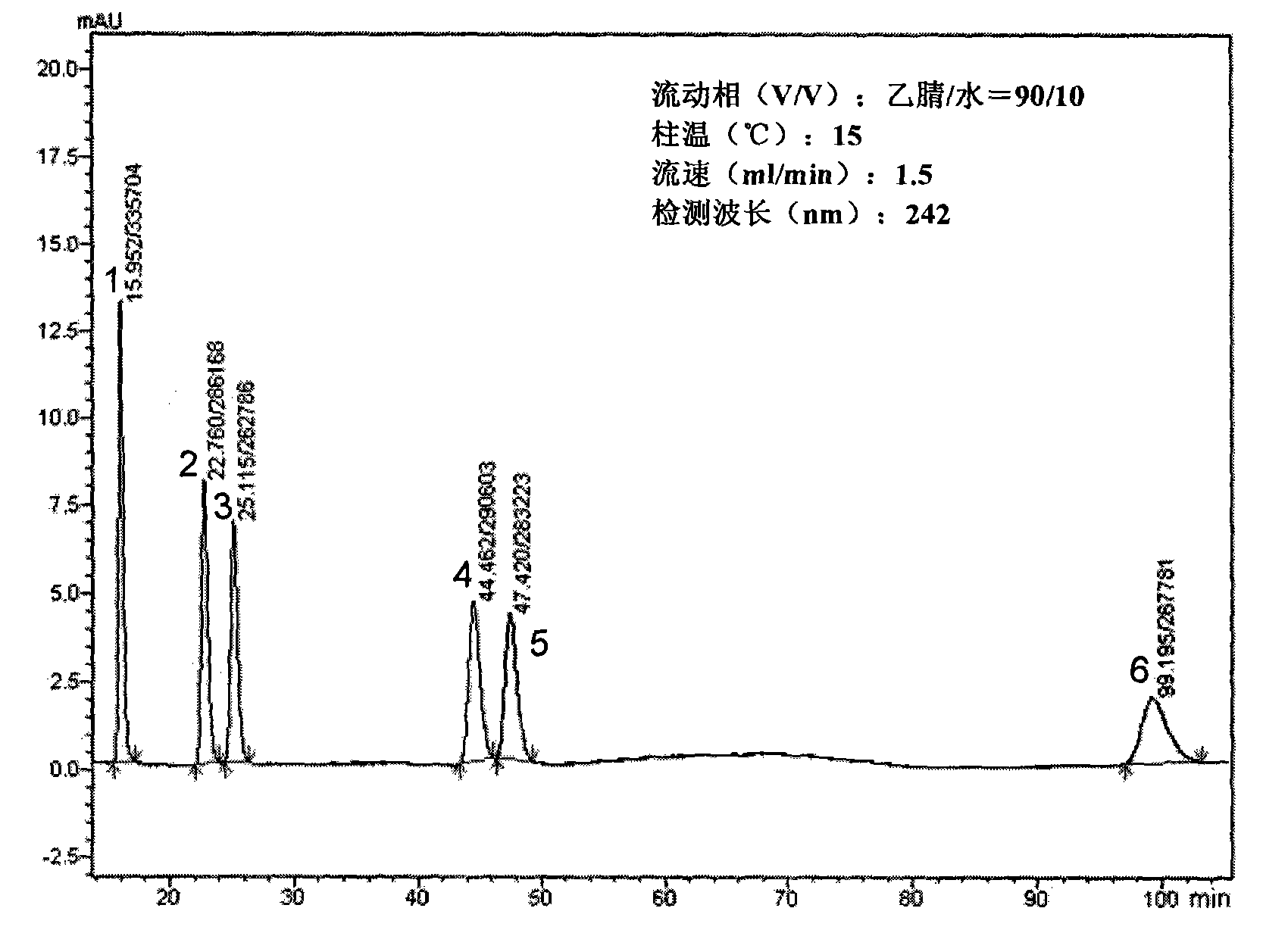

[0046] Mixed fatty acid analysis test. It is no longer repeated in the same part as in Example 1, and the difference is that the chromatographic separation conditions are as follows:

[0047] Chromatographic column: Kromasil C18 (250mm×4.6mm, 5μm)

[0048] Column temperature: 10°C

[0049] Mobile phase: acetonitrile: 5% CTAB=90:10

[0050] Flow rate: 1.5ml / min

[0051] Detection wavelength: 242±5nm

[0052] The test chromatogram is shown in Figure 2.

Embodiment 3

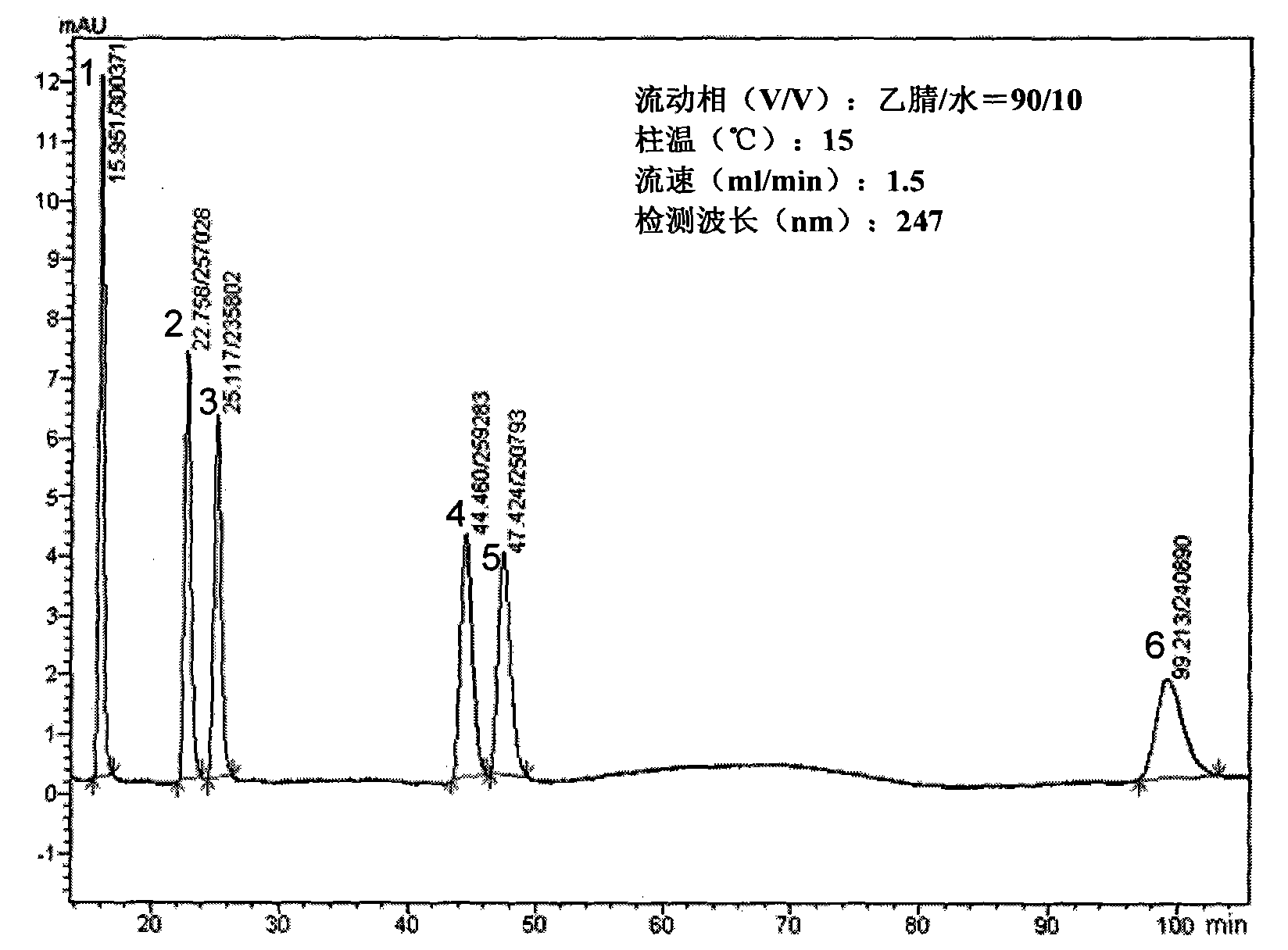

[0054] Mixed fatty acid analysis test. It is no longer repeated in the same part as in Example 1, and the difference is that the chromatographic separation conditions are as follows:

[0055] Chromatographic column: Kromasil C18 (250mm×4.6mm, 5μm)

[0056] Column temperature: 15°C

[0057] Mobile phase: acetonitrile: water = 95:5

[0058] Flow rate: 1.5ml / min

[0059] Detection wavelength: 242±5nm.

[0060] The test chromatogram is as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com