Method of extracting DHA and EPA in type of triglyceride from deep-sea fish

A technology of triglyceride and fatty acid triglyceride, which is applied in the field of biopharmaceuticals, can solve the problems of high acid value, high cost, and need decolorization for deep color, and achieves the effect of low acid value and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

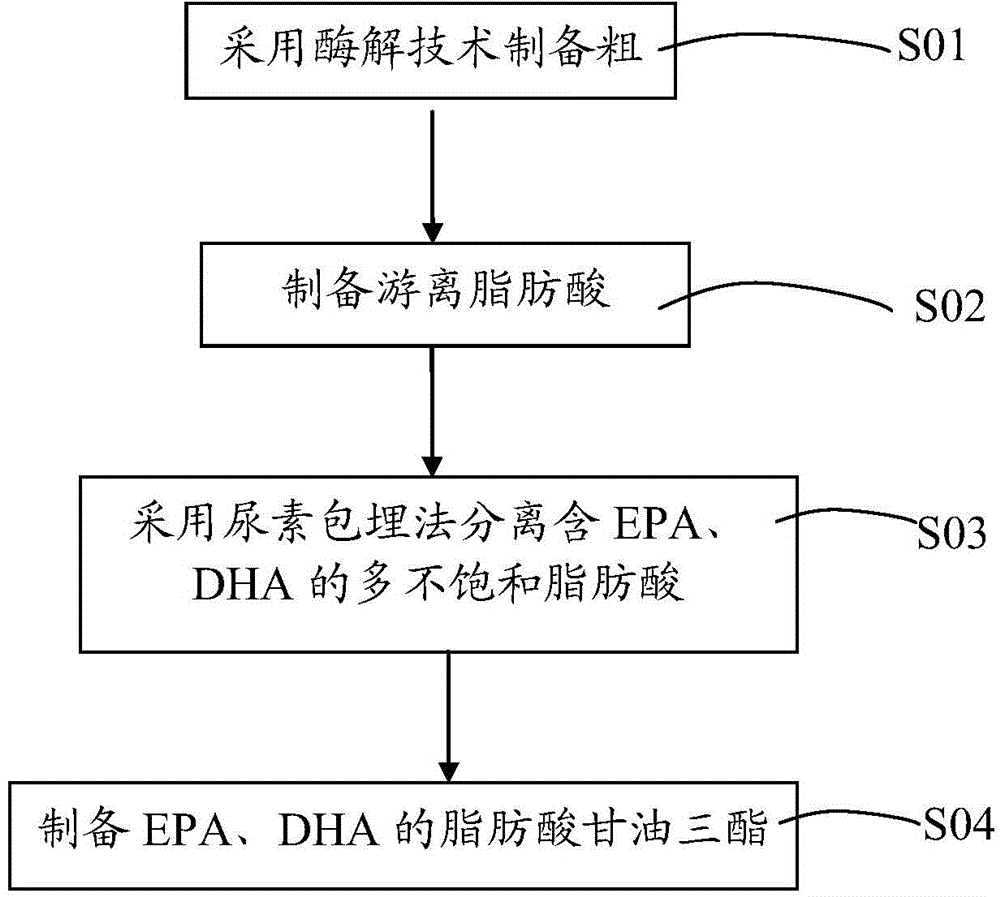

[0050] S11. Preparation of Crude Fish Oil

[0051]The crude fish oil of deep-sea fish was prepared by enzymatic hydrolysis technology. The deep-sea fish is crushed by a bone crusher to form a minced shape, weigh 600g of meat pulp, add water to seal it according to the ratio of meat:water=0.5:1 (m:m), and cook it at 85°C for 1 hour in a dark room under nitrogen. . The pH was adjusted to 8.0 using NaOH. Add trypsin with a mass fraction of 2%, and perform enzymatic hydrolysis in a dark room at room temperature (25°C) for 17 hours. After being centrifuged at 5000r / min for 20min, the enzymatic hydrolysis liquid in the upper layer was taken, which was the crude fish oil.

[0052] S12. Preparation of free fatty acids

[0053] Enzyme hydrolysis technology is used to hydrolyze the fish oil glyceride form of crude fish oil to obtain free fatty acids. Using lipase 1LVK-F100 as a catalyst, the enzyme dosage is 2%, the reaction temperature is 50°C, and the reaction time is 24h to obta...

Embodiment 2

[0060] S21. Preparation of Crude Fish Oil

[0061] The crude fish oil of deep-sea fish was prepared by enzymatic hydrolysis technology. The deep-sea fish is crushed by a bone crusher to form a minced shape. Weigh 600g of meat slurry, add water to seal it according to the ratio of meat:water=0.5:1 (w:w), and cook it at 85°C for 0.5 h. The pH was adjusted to 8.0 using NaOH. Add trypsin with a mass fraction of 1.5%, and perform enzymatic hydrolysis in a dark room at room temperature (20°C) for 15 hours. After being centrifuged at 4500r / min for 20min, the enzymatic hydrolysis solution in the upper layer was taken, which was the crude fish oil.

[0062] S22. Preparation of free fatty acid

[0063] Enzyme hydrolysis technology is used to hydrolyze the fish oil glyceride form of crude fish oil to obtain free fatty acids. Using lipase 1LVK-F100 as a catalyst, the enzyme dosage is 1.5%, the reaction temperature is 45°C, and the reaction time is 20h to obtain free fatty acids.

[...

Embodiment 3

[0070] S31. Preparation of Crude Fish Oil

[0071] The crude fish oil of deep-sea fish was prepared by enzymatic hydrolysis technology. The deep-sea fish is crushed by a bone crusher to form a minced shape, weigh 600g of meat pulp, add water to seal it according to the ratio of meat: water = 0.5:1.5 (m:m), and cook it at 90°C for 1 hour in a dark room with nitrogen. . The pH was adjusted to 8.0 using NaOH. Add trypsin with a mass fraction of 3%, and perform enzymatic hydrolysis in a dark room at 30°C for 15 hours. After being centrifuged at 6000r / min for 20min, the enzymatic hydrolysis solution in the upper layer was taken, which was the crude fish oil. Crude fish oil was tested according to the national standard GB / T17377-2008 "Gas Chromatographic Analysis of Fatty Acid Methyl Ester of Animal and Vegetable Oils".

[0072] S32. Preparation of free fatty acid

[0073] Enzyme hydrolysis technology is used to hydrolyze the fish oil glyceride form of crude fish oil to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of esterification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com