Oil soluble compound highly effective antirust additive and preparation method thereof

A rust-preventive additive, oil-soluble technology, applied in the directions of additives, petroleum industry, lubricating compositions, etc., to achieve the effect of wide application range, wide application temperature range and good oil solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] Preparation of oleic acid diethanolamide borate (steady state)

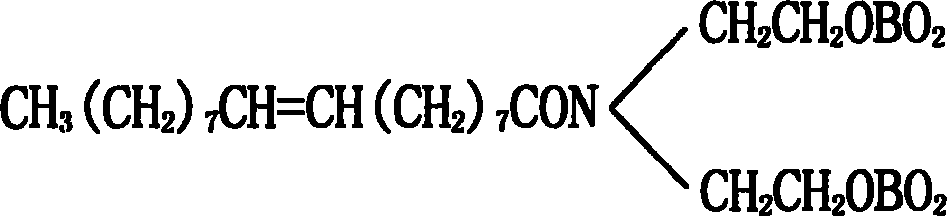

[0080] Oleic acid diethanolamide borate (steady state) is oleic acid diethanolamide borate modified by alkylphenol polyethylene oxide ether salts at a temperature of 120°C. Its structural formula is as follows:

[0081]

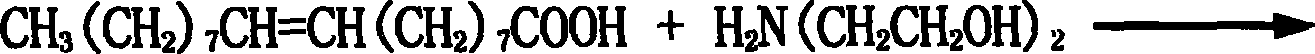

[0082] The direct synthesis reaction equation is as follows:

[0083]

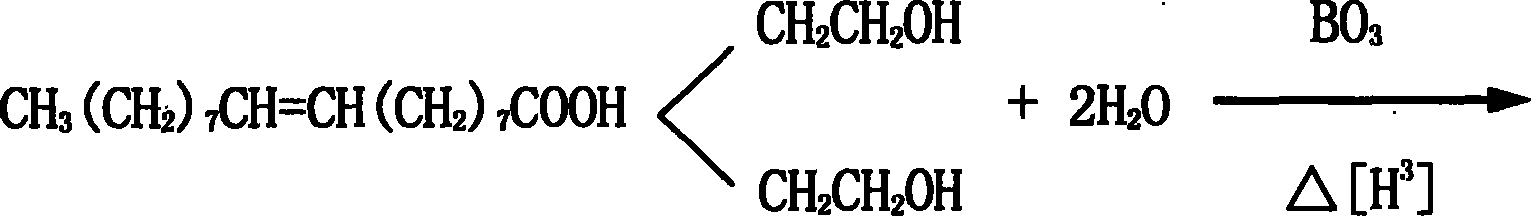

[0084]

[0085]

[0086] Add oleic acid into the reaction kettle, heat it to 100°C under the protection of nitrogen, add part of it at the ratio of oleic acid:diethanolamine=1:0.5mol, continue to heat up to 150-155°C, use NaOH standard solution to detect the content of free acid , when the content of free acid is lower than 1.5%, keep warm until the amine value of the reactant no longer changes to the end point. After being cooled to normal temperature, add boric acid in a molar ratio of oleic acid: boric acid = 1: 2, and use concentrated H 2 SO 4 As a catalyst, raise the temperature to 170°C, stir at c...

Embodiment 1

[0094] Get the content of each component as follows:

[0095] Glycyrrhizic acid: 6g

[0096] Diethanolamide borate oleate: 45g

[0097] Triethylhexadecylammonium bromide: 6g

[0098] N-dodecyl ammonium bromide: 3g

[0099] Di-n-octyl sebacate: 25g

[0100] Triethanolamine: 30g

[0101] Lanolin: 1.3g

[0102] According to the preparation method of the above-mentioned oil-soluble compound high-efficiency anti-rust additive, the oil-soluble compound high-efficiency anti-rust additive is prepared.

Embodiment 2

[0104] Get the content of each component as follows:

[0105] Lanolic acid: 14g

[0106] Diethanolamide borate oleate: 40g

[0107] Triethylhexadecylammonium bromide: 3g

[0108] N-octadecyl ammonium bromide: 2g

[0109] Di-n-octyl sebacate: 20g

[0110]Triethanolamine: 20.1g

[0111] Lanolol: 0.7g

[0112] According to the preparation method of the above-mentioned oil-soluble compound high-efficiency anti-rust additive, the oil-soluble compound high-efficiency anti-rust additive is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com