A method for cascade upgrading of lignite

A lignite and cascading technology, applied in the field of coal chemical industry, can solve the problems of increased accumulation of coal powder, high transportation costs, and reduced quality improvement efficiency, and achieve expansion of the drying zone and quality improvement zone, high resource utilization, and increased unit hourly output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

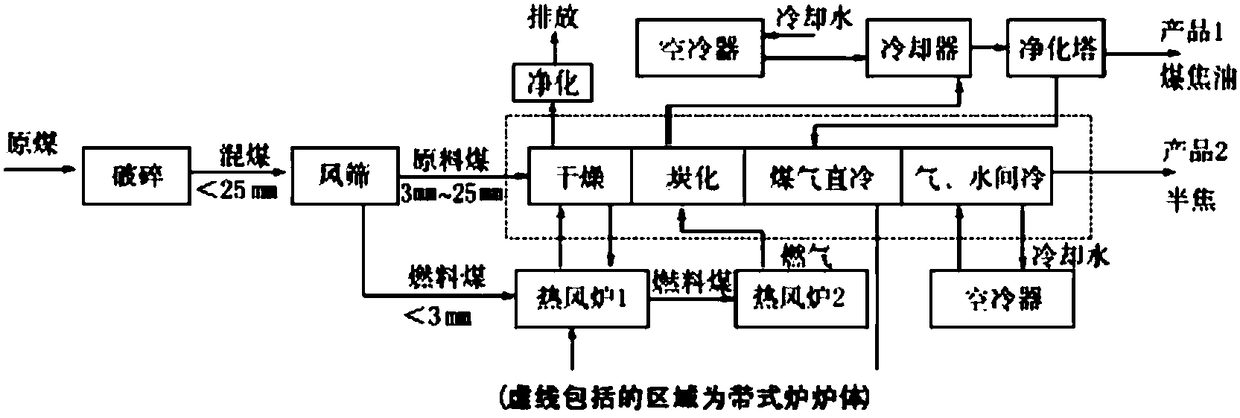

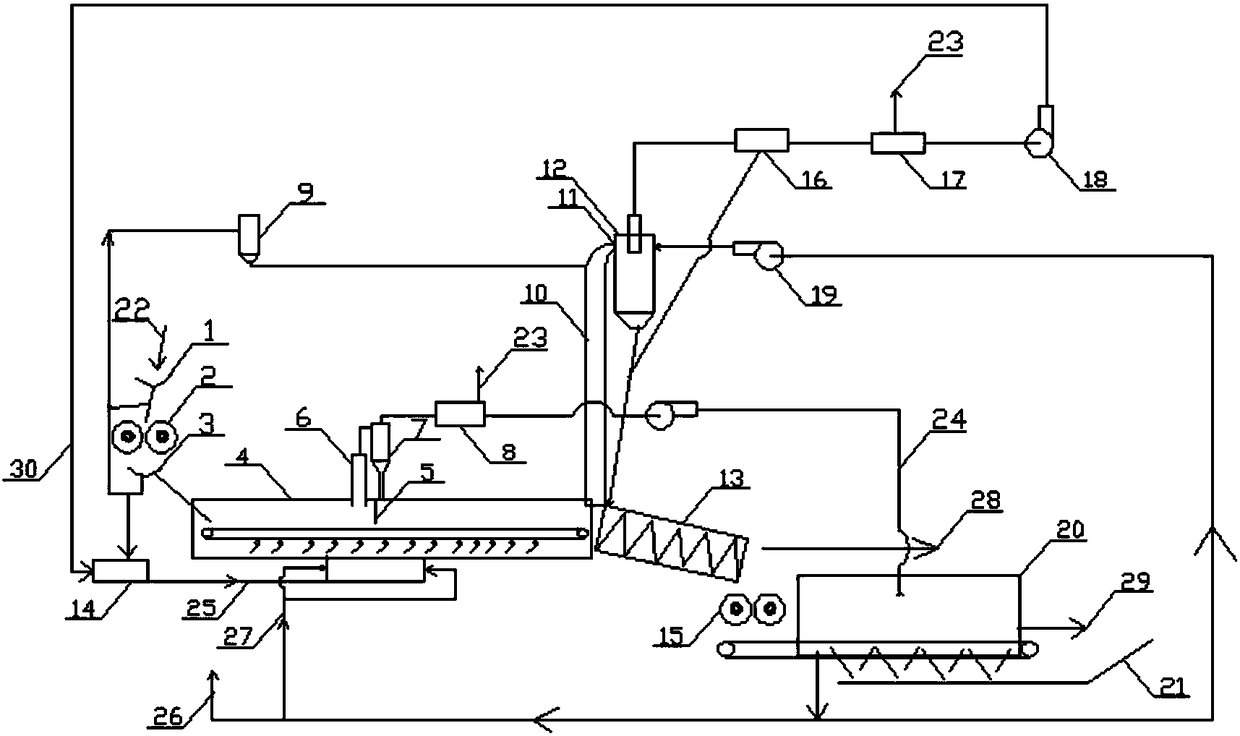

[0041] Attached below figure 2 Further state the technical scheme of the present invention:

[0042] 1. The lignite raw coal is first sieved by the coal sieve 1, and the particles smaller than 3mm enter the fine coal bunker 9, and the particles larger than 3mm enter the roller crusher 2, coarsely broken into particles below 25mm, and then sieved by the second coal sieve 3, The fine powder less than 3mm is divided into two parts: the first part enters the hot blast stove 14 to meet the use of the boiler that produces flue gas, and the second part enters the fine coal bunker 9, which absorbs waste heat and recovers heat, reduces the temperature of the lignite after upgrading, and reduces the risk of spontaneous combustion Probability; 3-25mm coal enters the upgrading equipment.

[0043] 2. The quality upgrading equipment 4 is divided into a drying area and a quality upgrading area by using a partition 5. The partition 5 can reform the cross section of the deformed material bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com