Powdery compound cement grinding aid and preparation method thereof

A technology for compounding cement and grinding aid, which is applied in the field of cement admixtures, can solve the problems of rapid growth in the early strength of cement of various mineral components of cement, poor performance in terms of cement performance and quality, and slow growth in later strength, etc. and over-grinding phenomenon, various performance and quality improvement, and the effect of increasing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

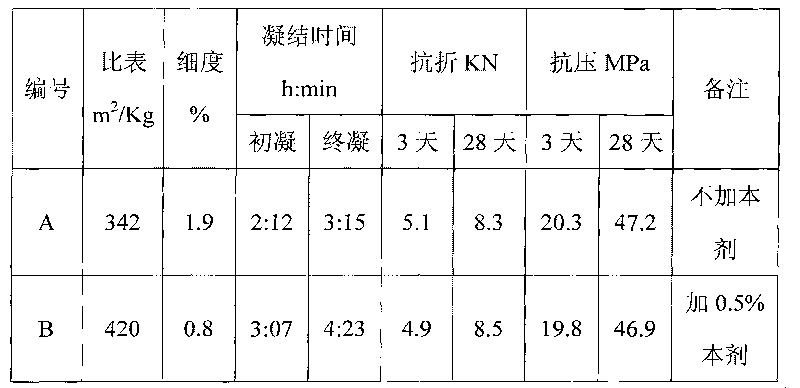

Image

Examples

Embodiment 1

[0019] Example 1: Each serving is 1 kg

[0020] A powder composite cement grinding aid is formed by mixing 2% liquid part and 98% powder part by weight, wherein the liquid part is made of the following raw materials in parts by weight, triethanolamine is 200 kg, Coconut acid diethanolamide 100 kg, water 300 kg, potassium dichromate 20 kg, sodium nitrite 20 kg, sodium hexametaphosphate 20 kg, SM Nai series water reducer 10 kg, calcium lignosulfonate 10 kg, soap 4 kg; wherein the powder part is made of the following raw materials in parts by weight, 100 kg of alum stone powder, 50 kg of sodium acetate, 100 kg of ferrous sulfate heptahydrate, 50 kg of sodium thiosulfate, 150 kg of limestone powder, and fly ash 150 kg, Glauber's salt 100 kg. The preparation method comprises the following steps: (1) Firstly, potassium dichromate, sodium nitrite, sodium hexametaphosphate, SM nano-based water reducing agent and calcium lignosulfonate in the liquid part are dissolved in water in prop...

Embodiment 2

[0021] Example 2: Each serving is 1 kg

[0022]A powder composite cement grinding aid is formed by mixing 5% liquid part and 95% powder part by weight, wherein the liquid part is made of the following raw materials in parts by weight, triethanolamine is 500 kg, Coconut acid diethanolamide 300 kg, water 600 kg, potassium dichromate 30 kg, sodium nitrite 50 kg, sodium hexametaphosphate 30 kg, SM Nai series water reducing agent 20 kg, calcium lignosulfonate 30 kg, soap 5 kg; wherein the powder part is made of the following raw materials in parts by weight, 300 kg of alum stone powder, 100 kg of sodium acetate, 300 kg of ferrous sulfate heptahydrate, 150 kg of sodium thiosulfate, 250 kg of limestone powder, and fly ash 300 kg, Glauber's salt 400 kg. The preparation method comprises the following steps: (1) Firstly, potassium dichromate, sodium nitrite, sodium hexametaphosphate, SM nano-based water reducing agent and calcium lignosulfonate in the liquid part are dissolved in water...

Embodiment 3

[0023] Example 3: Each serving is 1 kg

[0024] A powder composite cement grinding aid is formed by mixing 3% liquid part and 97% powder part by weight, wherein the liquid part is made of the following raw materials in parts by weight, triethanolamine is 200 kg, Coconut acid diethanolamide 300 kg, water 300 kg, potassium dichromate 25 kg, sodium nitrite 50 kg, sodium hexametaphosphate 30 kg, SM Nai series water reducing agent 15 kg, calcium lignosulfonate 20 kg, soap 4 kg; wherein the powder part is made of the following raw materials in parts by weight, 150 kg of alum stone powder, 100 kg of sodium acetate, 100 kg of ferrous sulfate heptahydrate, 100 kg of sodium thiosulfate, 200 kg of limestone powder, and fly ash 150 kg, Glauber's salt 200 kg. The preparation method comprises the following steps: (1) Firstly, potassium dichromate, sodium nitrite, sodium hexametaphosphate, SM nano-based water reducing agent and calcium lignosulfonate in the liquid part are dissolved in wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com