Cement preparation method

A cement preparation and cement technology, which is applied in the direction of cement production, etc., can solve the problems of waste of coal and electric energy consumption, etc., and achieve the effects of reducing the consumption ratio of clinker, increasing the output per unit hour, and increasing the stacking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In this embodiment, the main ingredient in the raw meal is limestone, and the specific surface area of some ultra-fine limestone powder in the kiln dust and raw meal vertical mill system can reach 1000-1200m 2 / kg, far exceeding the specific surface area of general raw meal and cement. If raw meal is sintered into the kiln and then ground into cement, it will cause waste of coal and electricity consumption in the process of calcination and cement grinding.

[0018] Applying this ultra-fine powder to cement mills instead of limestone as a mixed material can make full use of the characteristics of ultra-fine powder, increase the bulk density of cement particles, make cement particle distribution closer to the particle size distribution requirement of Fuller curve, and increase cement strength . When the ultra-fine powder is mixed into the cement mill as a mixed material, it does not need to be ground again, and can be directly selected as the finished product by the class...

Embodiment 2

[0020] The invention discloses a method for preparing cement by using a mixture of kiln dust and a vertical mill superfine limestone powder as the mixture.

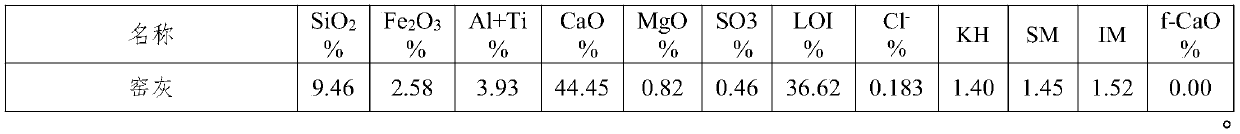

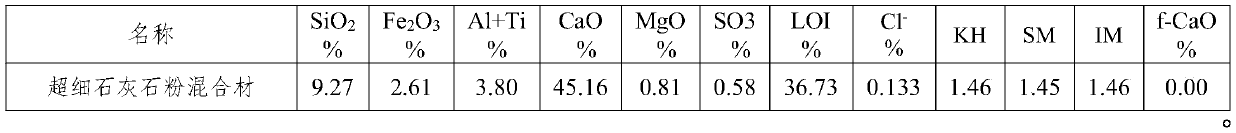

[0021] The chemical composition (mass ratio) of the mixture of kiln dust and vertical mill ultrafine limestone powder is shown in the following table

[0022]

[0023] Table 1

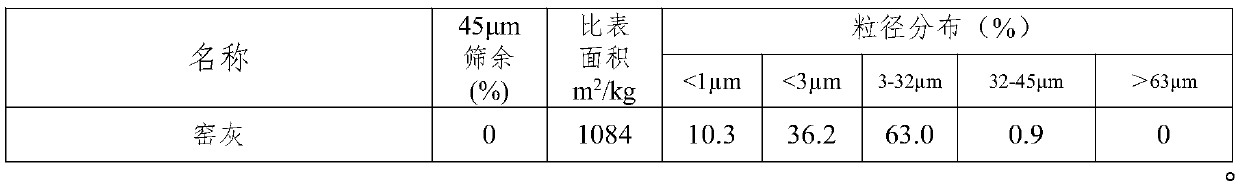

[0024] The physical properties of the mixture of kiln dust and vertical mill ultrafine limestone powder are shown in the following table

[0025]

[0026] Table 2

[0027] From the inspection data, the particle size distribution of the mixture of kiln dust and vertical mill ultrafine limestone powder The content of particles 2 / kg, so it can be applied to cement mills instead of limestone as a mixed material, using the characteristics of ultra-fine powder to increase the output per mill, increase the bulk density of finished cement particles, and increase the strength of cement.

Embodiment 3

[0029] In this embodiment, after the superfine powder is incorporated, the cement strength can be significantly increased under the premise of the clinker content unchanged, so the clinker consumption ratio in the cement can be reduced to a certain extent. Taking the clinker small grinding cement as the benchmark, the cement strength test situation after adding ultra-fine powder is shown in the following table:

[0030]

[0031] table 3

[0032] From the comparative test situation, after adding kiln dust and ultra-fine limestone powder, under the premise that the clinker mixing ratio is reduced by 5%, the compressive strength of cement at 3 days and 28 days only decreases by 0.5-1.5Mpa, which is still To maintain a higher late strength, it is proved that the incorporation of kiln dust and ultrafine limestone powder can effectively reduce the proportion of clinker consumption in cement.

[0033] Because the mixture of kiln dust and vertical mill superfine limestone powder is very fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com