A method for widening trolley sideboard of sintering ring cooler

A technology of sintered annular cooler and annular cooler, which is applied in the direction of lighting and heating equipment, furnace types, furnaces, etc., can solve the problems of high one-time investment, difficult cooling output, large floor area, etc., and achieve design and manufacturing The effect of low difficulty, improving loading and operating efficiency, and increasing the output per unit hour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

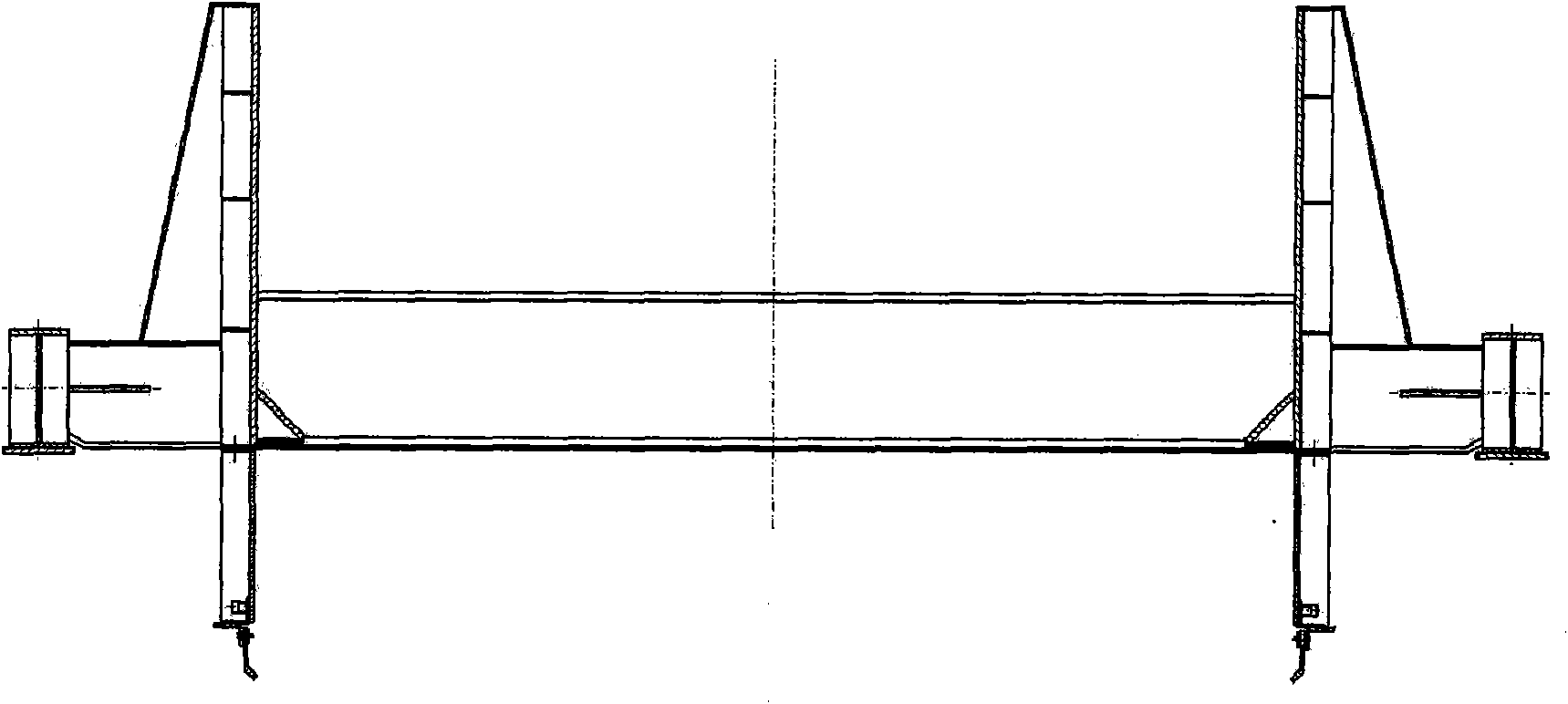

Image

Examples

Embodiment Construction

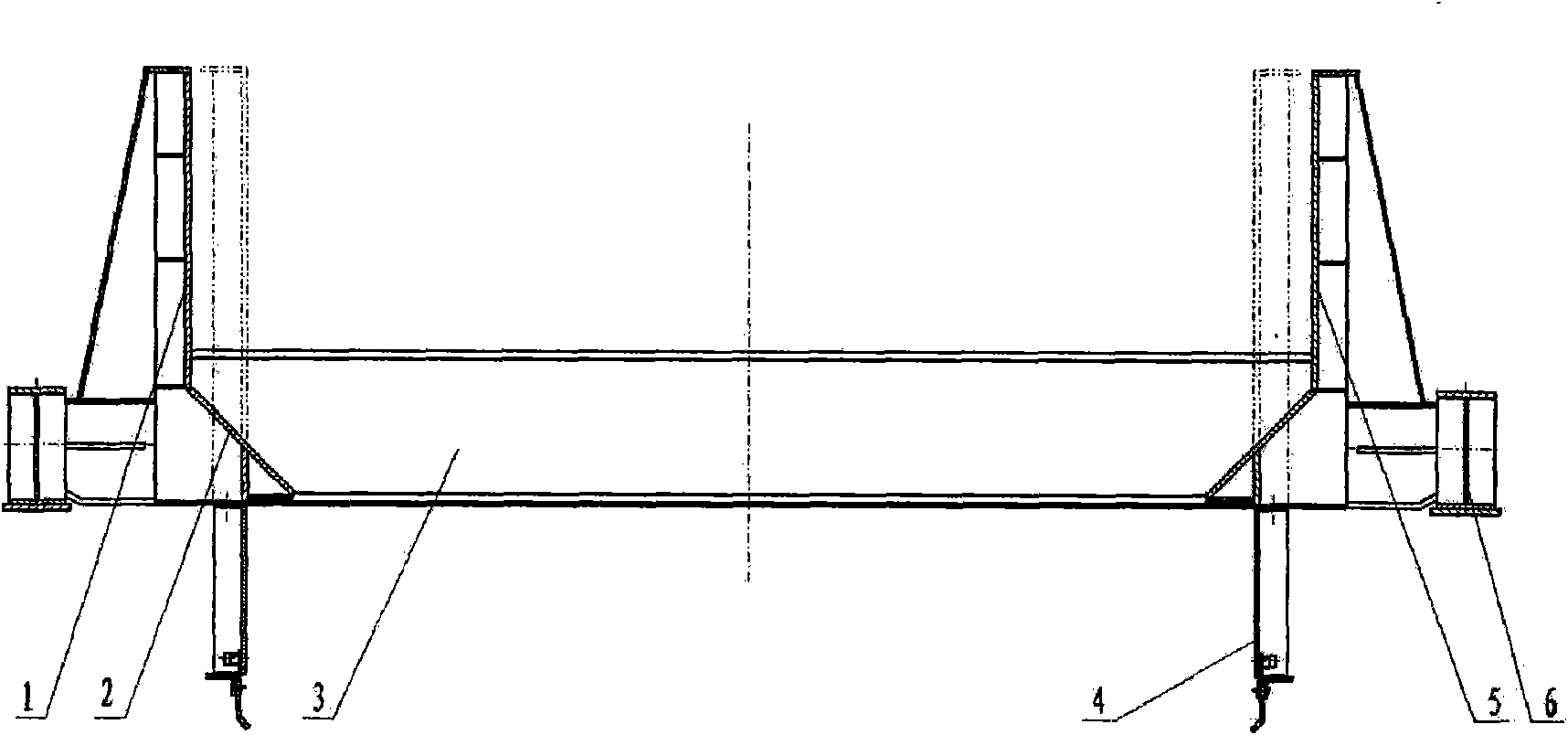

[0013] Such as figure 2 It is a specific embodiment of the present invention. This technology can be used to transform the existing ring cooler, and it can also be used in the new design of the ring cooler.

[0014] The implementation method is as follows: first, based on the triangular beam 3 of the trolley, at the intersection of the triangular beam 3 and the bellows area 4 below the trolley, an outwardly widened trolley slant plate 2 is added, and the angle between the trolley slant plate 2 and the horizontal plane is Between 30° and 60°, and then move the trolley fence outward according to the final fence width (this width is 100-1000mm larger than the width of the fence without widening). When widening the trolley fence, it is necessary to adjust and process the fence, that is, to smoothly connect the trolley outer fence 1, the trolley inner fence 5 and the trolley slant 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com