Powder modified excitant for finely grinding fly ash and preparation method thereof

A powder modification and activator technology, applied in cement production and other directions, can solve the problems of low activity of fly ash, limitation of mass use of fly ash, and low early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

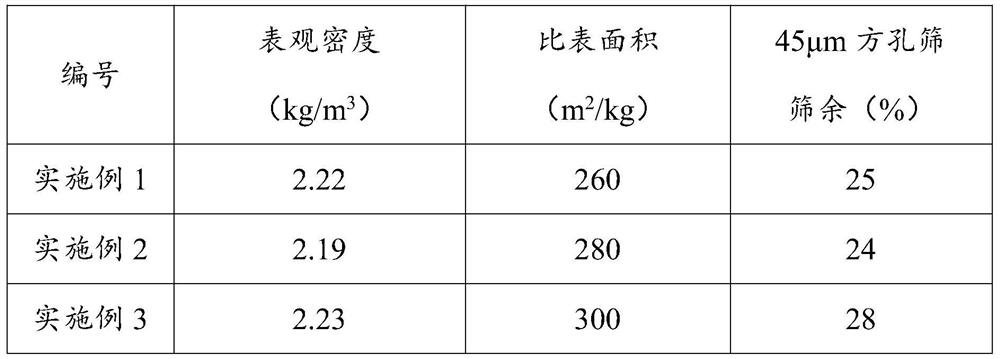

Embodiment 1

[0029] A powder modified activator for pulverizing fly ash, comprising the following raw materials in mass percentage: 7.2% of modifier, 25% of sacrificial agent, 10% of reinforcing activator, and 57.8% of anhydrite carrier. Among them, the modifier contains 2% lignosulfonate, 5% phosphate 1#, and 0.2% phosphate 2#; Anhydrite.

[0030] Wherein, the lignosulfonate is calcium lignosulfonate with a molecular weight of 1000-8000 and containing 20% of reducing sugar. Phosphate 1# is sodium hexametaphosphate, industrial grade, P 2 o 5 70%. Phosphate 2# is sodium tripolyphosphate, industrial grade, content 98%. Yuanmingfen is industrial grade, content ≥ 99.2%. Sodium thiosulfate is industrial grade, containing 5 crystal waters, and the content is 96%. Anhydrite 0.045mm sieve residue is 30%, SO 3 The content is 52%, and the crystal water is 3%, which is natural anhydrite.

[0031] The preparation method of the above-mentioned powder modified activator for grinding fine fly a...

Embodiment 2

[0035] A powder modified activator for pulverizing fly ash, comprising the following raw materials in mass percentage: 8.3% of modifier, 20% of sacrificial agent, 15% of reinforcing activator, and 56.7% of anhydrite carrier. Among them, the modifier contains 1% of lignosulfonate, 7% of phosphate 1#, and 0.3% of phosphate 2#; Anhydrite.

[0036] Wherein, the lignosulfonate is calcium lignosulfonate with a molecular weight of 1000-5000 and containing 25% of reducing sugar. Phosphate 1# is sodium hexametaphosphate, industrial grade, P 2 o 5 75%. Phosphate 2# is sodium tripolyphosphate, industrial grade, with a content of 97%. Yuanmingfen is industrial grade, content ≥ 99.5%. Sodium thiosulfate is industrial grade, containing 5 crystal waters, the content is 97%. Anhydrite 0.045mm sieve residue is 20%, SO 3 The content is 50%, and the crystal water is 2%, which is natural anhydrite.

[0037] The preparation method of the above-mentioned powder modified activator for grindi...

Embodiment 3

[0041] A powder modified activator for pulverizing fly ash, comprising the following raw materials in mass percentage: 15.5% of modifier, 30% of sacrificial agent, 20% of reinforcing activator, and 34.5% of anhydrite carrier. Among them, the modifier contains 5% lignosulfonate, 10% phosphate 1#, and 0.5% phosphate 2#; Anhydrite.

[0042] Wherein, the lignosulfonate is calcium lignosulfonate with a molecular weight of 1000-10000 and containing 30% of reducing sugar. Phosphate 1# is sodium hexametaphosphate, industrial grade, P 2 o 5 was 78%. Phosphate 2# is sodium tripolyphosphate, industrial grade, content 99%. Yuanmingfen is industrial grade, content ≥ 99.5%. Sodium thiosulfate is industrial grade, containing 5 crystal waters, and the content is 98%. Anhydrite 0.045mm sieve residue is 40%, SO 3 The content is 54%, and the crystal water is 4%, which is natural anhydrite.

[0043]The preparation method of the above-mentioned powder modified activator for grinding fine f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com