Grinding aid for preparing cementing material for filling and dry stacking of mines

A technology for cementitious material and mine filling, which is used in the field of preparation of mine filling, grinding aid, and grinding aid for cementitious materials for dry heap, can solve the problems of difficult grinding and easy paste balls, etc., to improve fluidity, The effect of improving early strength and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 is used to prepare a grinding aid for cementing materials for mine filling and dry pile, and its composition is as follows:

[0031] Methacrylic acid modified polymeric polyol 25%

[0032] Modified diethanol monoisopropanolamine 10%

[0033] Molasses 15%

[0034] Sodium thiocyanate 7%

[0035] Sodium metaaluminate 7%

[0036] Sodium fluorosilicate 7%

[0037] The balance is water, and the total amount is 100%.

[0038] The preparation method of methacrylic acid modified polymeric polyol is as follows: In the reactor, add 1.3 parts of methacrylic acid and 1 part of polymeric polyol, stir evenly, and react at 70-80°C for 1.5 hours to obtain methacrylic acid modified Polymeric polyols.

[0039] The preparation method of the present invention is as follows: sodium thiocyanate, sodium metaaluminate and sodium fluorosilicate are added to water according to the formula ratio, and after stirring and dissolving, the formula ratio is stirred while adding sucrose molasses, N,N-bis(2-...

Embodiment 2 to Embodiment 6

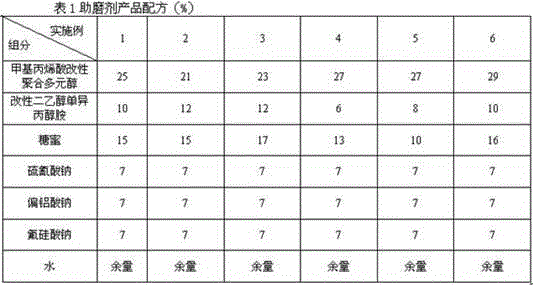

[0041] According to the content of each component specified in Table 1 below, the products of Example 2 to Example 6 were prepared according to the method of Preparation Example 1, and the grinding aid products 2 to 6 of the cementing material for mine filling and dry pile were obtained respectively .

[0042]

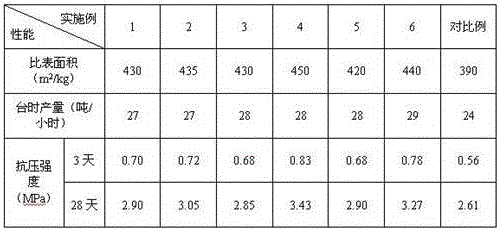

[0043] The grinding aid products prepared in Examples 1 to 6 were blended into the mixed material according to 0.03% of the mass of the gelling material, and ball milled to produce 6 kinds of gelling materials. Stir and mix the gelling agent with 68% full tailings at a lime-sand ratio of 1:8, which is the slurry for mine filling. The slurry is put into a test mold of 70.7×70.7×70.7, at a temperature of 20℃ and a humidity of 90 % Curing in a curing box, demoulding after 24 hours, and continue curing in a constant temperature and humidity box under this condition to test the compressive strength of different childbearing ages. The products produced with cement grinding aid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com