Preparation method of modified molasses waste liquid and cement grinding aid

A technology for modifying molasses waste liquid, which is applied in the field of cement grinding aids added to cement, can solve the problems of functional group concentration, inability to fully play the role of grinding aid and hydration aid, and reduce the fineness and specific surface area , strength improvement, and the effect of increasing the setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

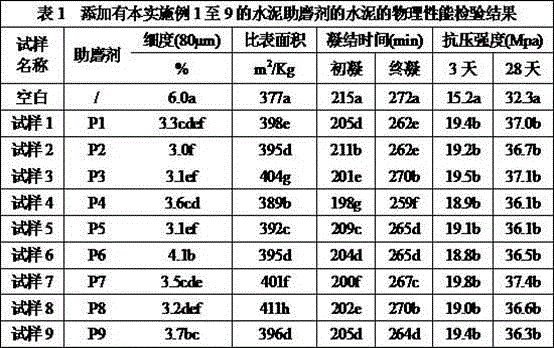

Examples

Embodiment 1

[0022] Embodiment 1, the preparation method of the modified molasses waste liquid of this embodiment, which comprises the following steps.

[0023] Step A, take an appropriate amount of molasses waste liquid, adjust the pH value of the molasses waste liquid with sodium hydroxide solution, to pH=9 of the molasses waste liquid, filter under normal pressure to obtain molasses alcohol filtrate A.

[0024] In step B, the acetic acid solution is added to the molasses alcohol filtrate A obtained in step A, and the pH=2 of the molasses alcohol filtrate A is adjusted to obtain molasses waste liquid B.

[0025] Step C, put into the autoclave after mixing the molasses waste liquid B obtained in step B with 35% hydrogen peroxide in a volume ratio of 1:0.1, the pressure in the autoclave is 20KPa, and the temperature is 90 ℃ under the condition, so The molasses waste liquid B is fully reacted with 35% industrial hydrogen peroxide to obtain the molasses waste liquid C.

[0026] In step D, t...

Embodiment 2

[0028] Embodiment 2, the preparation method of the modified molasses waste liquid of this embodiment, which comprises the following steps.

[0029] Step A, take an appropriate amount of molasses waste liquid, adjust the pH value of molasses waste liquid with sodium hydroxide solution, to pH=10 of molasses waste liquid, filter under normal pressure to obtain molasses alcohol filtrate A.

[0030] In step B, the acetic acid solution is added to the molasses alcohol filtrate A obtained in step A, and the pH=2 of the molasses alcohol filtrate A is adjusted to obtain molasses waste liquid B.

[0031] In step C, the molasses waste liquid B obtained in step B and 35% hydrogen peroxide are mixed in a volume ratio of 1:0.1 and put into the autoclave. The pressure in the autoclave is 30KPa and the temperature is 100 ℃. The molasses waste liquid B is fully reacted with 35% industrial hydrogen peroxide to obtain the molasses waste liquid C.

[0032] In step D, the pH value of the molasses...

Embodiment 3

[0034] Embodiment 3, the preparation method of the modified molasses waste liquid of this embodiment, which comprises the following steps.

[0035] Step A, take an appropriate amount of molasses waste liquid, adjust the pH value of molasses waste liquid with sodium hydroxide solution, to pH=11 of molasses waste liquid, filter under normal pressure to obtain molasses alcohol filtrate A.

[0036] In step B, the acetic acid solution is added to the molasses alcohol filtrate A obtained in step A, and the pH=3 of the molasses alcohol filtrate A is adjusted to obtain molasses waste liquid B.

[0037] In step C, the molasses waste liquid B obtained in step B and 35% hydrogen peroxide are mixed in a volume ratio of 1:0.2 and put into the autoclave. The pressure in the autoclave is 30KPa and the temperature is 100 ℃. The molasses waste liquid B is fully reacted with 35% industrial hydrogen peroxide to obtain the molasses waste liquid C.

[0038] In step D, the pH value of the molasses...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com