Composite film capable of prolonging shelf life of sausage with modified casing and preparation method of composite film

A technology of shelf life and composite film, which is applied in the chemical treatment and slaughtering of sausage casings, natural sausages, etc., to achieve the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

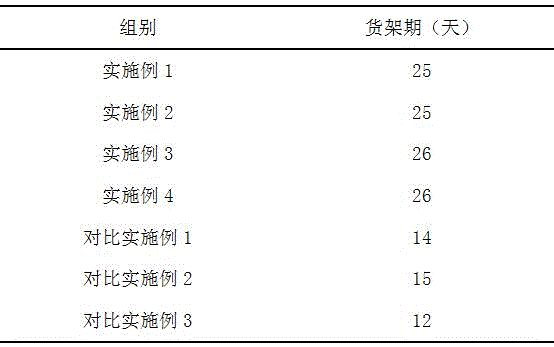

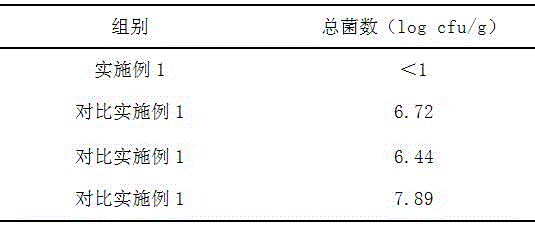

Examples

Embodiment 1

[0028] Preparation of composite membrane:

[0029] Weigh 0.8g of chitosan (Aladdin, C105799) and dissolve it in 30g of 2% acetic acid solution, add 0.24g of glycerol at the same time, homogenize at 6000r / min for 30min, place in a water bath and heat to 50°C, And continue to stir for 30min. After the chitosan is completely dissolved, add 0.5g of tea polyphenols, heat and stir at 50°C for 1h, and place the homogenized solution under 0.10MPa vacuum for degassing treatment for 10min. The obtained chitosan / tea polyphenol composite membrane solution was cast on a size of 20×20cm 2 A plexiglass plate covered with polyvinylidene chloride (PVDC) film, the coating amount is 6mL / cm 2 , and dried in a blower drying oven at 50°C for 12-24 hours, peel off the film after drying, and equilibrate the obtained composite film at 75% ambient humidity for 48 hours before use.

[0030] Preparation of modified casing sausage:

[0031] 1) After desalting the natural pig casings, immerse them in a ...

Embodiment 2

[0037] Preparation of composite membrane:

[0038] Weigh 1.2g of chitosan (Aladdin, C105799) and dissolve it in 30g of 2% acetic acid solution, add 0.36g of glycerol at the same time, homogenize at 6000r / min for 30min, place in a water bath and heat to 50°C. And continue to stir for 30min. After the chitosan is completely dissolved, add 0.6g of tea polyphenols, heat and stir at 50°C for 1h, and place the homogenized solution under 0.10MPa vacuum for 10min. The obtained chitosan / tea polyphenol composite membrane solution was cast on a size of 20×20cm 2 A plexiglass plate covered with polyvinylidene chloride (PVDC) film, the coating amount is 6mL / cm 2 , and dried in a blower drying oven at 50°C for 12-24 hours, peel off the film after drying, and equilibrate the obtained composite film at 75% ambient humidity for 48 hours before use.

[0039] Preparation of modified casing sausage:

[0040] 1) After desalting the natural pig casings, immerse them in a mixed solution of soybea...

Embodiment 3

[0046] Preparation of composite membrane:

[0047] Weigh 1g of chitosan (Aladdin, C105799) and dissolve it in 30g of 2% acetic acid solution, add 0.3g of glycerol at the same time, homogenize at 6000r / min for 30min, place in a water bath and heat to 50°C, and Continue to stir for 30 minutes. After the chitosan is completely dissolved, add 0.4 g of tea polyphenols, heat and stir at 50 ° C for 1 hour, and place the homogenized solution under 0.10 MPa vacuum for 10 minutes. The chitosan / tea polyphenol composite film was cast in a size of 20×20cm 2 A plexiglass plate covered with polyvinylidene chloride (PVDC) film, the coating amount is 6mL / cm 2 , and dried in a blower drying oven at 50°C for 12-24 hours, peel off the film after drying, and equilibrate the obtained composite film at 75% ambient humidity for 48 hours before use.

[0048] Preparation of modified casing sausage:

[0049] 1) After desalting the natural pig casings, immerse them in a mixed solution of soybean lecithi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com