Preparation method of high meat viscosity collagen sausage casings and the high meat viscosity collagen sausage casings

A collagen casing and stickiness technology, which is applied in the field of collagen casing processing, can solve the problems of meat separation, collagen casing heat shrinkage, and poor meat viscosity, etc., and achieve strong water retention, superior shrinkage, and improved barrier properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

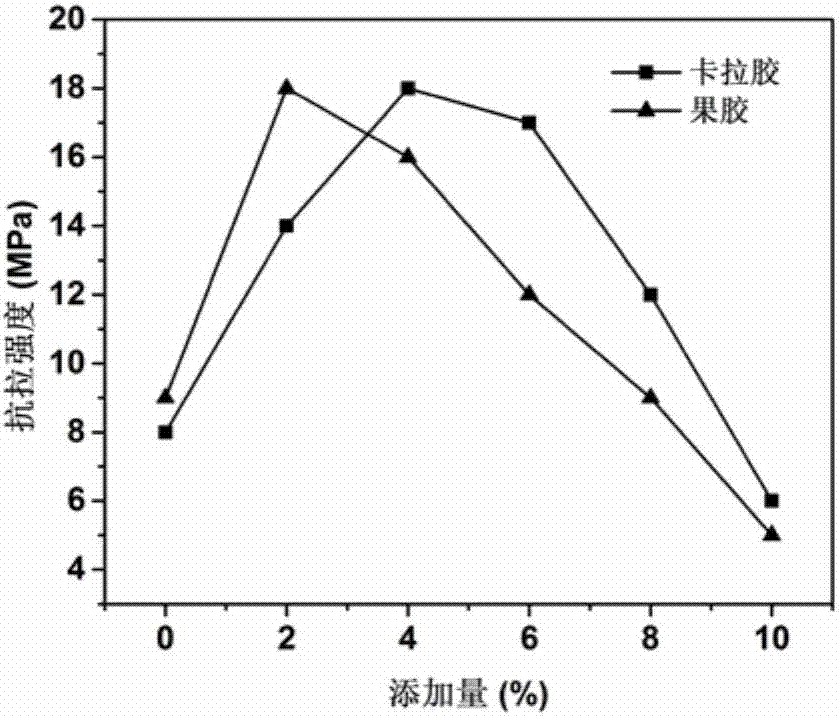

[0034] (1) Macromolecule dispersion: configure 0.6wt% hydrochloric acid solution, add 2% carrageenan to the hydrochloric acid solution, disperse at a high speed for 1 min at 5000 rpm to make the carrageenan well and evenly disperse, and obtain a carrageenan acid dispersion;

[0035] (2) Compounding: mix the carrageenan acid dispersion prepared in (1) with an equal volume of skin pulp, add 2.5% glycerin and knead to prepare a collagen group, and store at 10°C for 12 hours;

[0036] (3) Extrusion and solidification: After the collagen group is homogeneously (30MPa) filtered under a pressure of 30MPa, it is extruded through an extruder with a rotation speed of 20rpm, and air and ammonia are introduced, and the pressure is 20psi;

[0037] (4) Water washing: the casings are washed in a water washing tank for 8 minutes to remove residual salts;

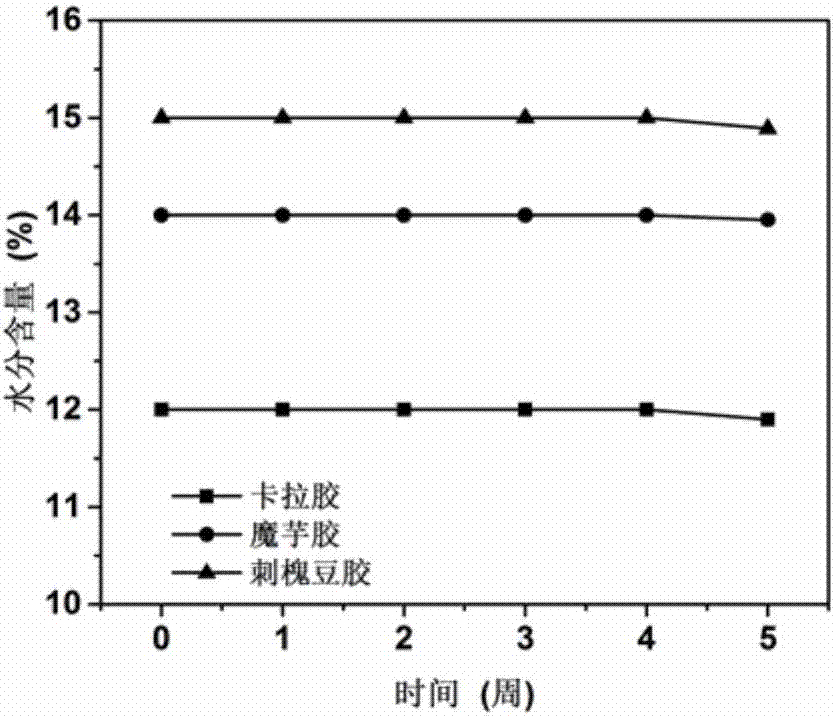

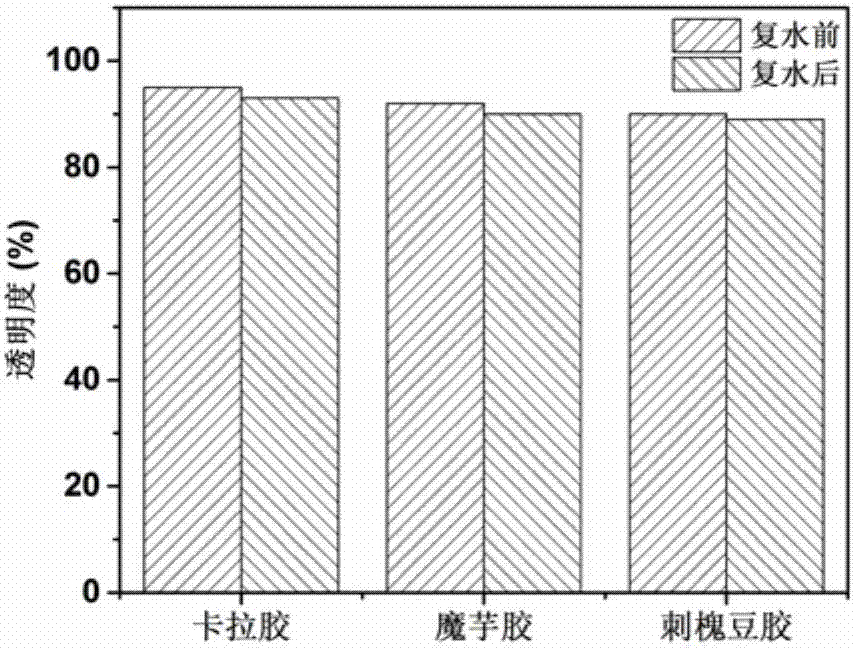

[0038] (5) Drying and re-humidification: after washing, the casings were dried for 18 minutes on a continuous hot air drying line at a tem...

Embodiment 2

[0043](1) Macromolecular dispersion: configure 0.7wt% hydrochloric acid solution, add 3% konjac gum to the hydrochloric acid solution, disperse at a high speed for 1 min at 5000rpm to make the konjac gum well and evenly disperse, and obtain the konjac gum acid dispersion;

[0044] (2) Compounding: mix the konjac gum acid dispersion prepared in (1) with an equal volume of skin pulp, add 5% glycerin and knead to prepare a collagen group, and store it at 8°C for 12 hours;

[0045] (3) Extrusion and solidification: After the collagen group is homogeneously filtered at a pressure of 30MPa, it is extruded through an extruder with a rotation speed of 30rpm, and air and ammonia are introduced at a pressure of 30psi;

[0046] (4) Water washing: the casings are washed in a water washing tank for 10 minutes to remove residual salts;

[0047] (5) Drying and re-humidification: After washing, the casings are dried for 16 minutes through a continuous hot-air drying line at a temperature of 7...

Embodiment 3

[0052] (1) Macromolecule dispersion: configure 0.8wt% hydrochloric acid solution, add 3.75% locust bean gum to the hydrochloric acid solution, disperse at a high speed at 5000rpm for 1min to make the locust bean gum well and uniformly dispersed, and obtain the locust bean gum acid dispersion;

[0053] (2) Compounding: mix the locust bean gum dispersion prepared in (1) with an equal volume of skin pulp, add 15% glycerin and knead to prepare a collagen group, and store at 8°C for 14 hours;

[0054] (3) Extrusion and solidification: After the collagen group is homogeneously filtered under a pressure of 40MPa, it is extruded through an extruder with a rotation speed of 35rpm, and air and ammonia are introduced at a pressure of 30psi;

[0055] (4) Water washing: the casings are washed in a water washing tank for 10 minutes to remove residual salts;

[0056] (5) Drying and re-humidification: After washing, the casings are dried for 15 minutes on a continuous hot air drying line at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com