Orange-flavor sausage and processing method thereof

A processing method and sausage technology, which is applied in the field of food processing, can solve problems such as low tensile strength, nitrite poisoning, and potential safety hazards, and achieve the effects of reducing frictional resistance, increasing tensile strength, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

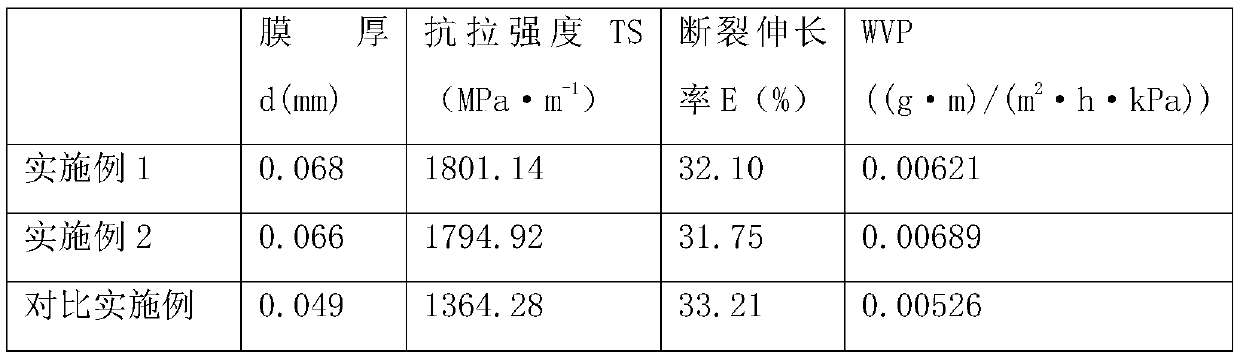

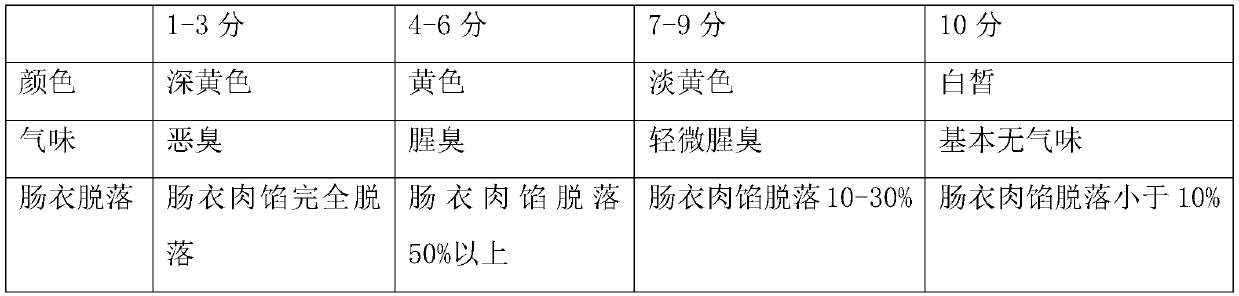

Examples

Embodiment 1

[0035] Embodiment 1: sausage preparation one

[0036] The present embodiment takes each raw material respectively according to the following weights:

[0037]Weigh pork 5kg (fat and thin 1:1), salt 150g, sugar 100g, white wine 50g, sodium nitrite 0.25g, monascus red pigment 1g, sodium erythorbate 2.25g, fresh orange peel 100g, orange flavor food essence 10g, starch 200g, cut the fresh orange peel into about 0.5cm fresh orange peel.

[0038] The modified pig casing preparation method in the present embodiment is as follows:

[0039] A. Softening treatment of pig casings: Take 2kg of pig casings that have been removed from the oil and cleaned, mix them with 166.7g of cornstarch and put them in a basin, knead the pig casings for about 5 minutes, then wash with water with a pH of 7-7.5 to clean the cornstarch Clean, then add 133.33g glycerin, 2.67g sodium pyrophosphate, water and pig casings into the pot and stir evenly, then let it stand at 10°C for 1 hour, then turn the inner ...

Embodiment 2

[0049] Embodiment 2: sausage preparation two

[0050] In this embodiment, each raw material is weighed according to the following weights: 5 kg of pork (fat and thin 1:1), 150 g of salt, 100 g of sugar, 50 g of white wine, 0.25 g of sodium nitrite, 1 g of monascus red pigment, 2.25 g of sodium erythorbate, 100g of fresh orange peel, 10g of orange flavor edible essence, 200g of starch, cut the fresh orange peel into diced fresh orange peel of about 0.5cm.

[0051] The preparation method of the modified pig casing in the present embodiment is as follows:

[0052] A. Softening treatment of pig casings: Take 2kg of pig casings that have been removed from the oil and cleaned, mix them with 166.7g of cornstarch, put them into a basin, knead the pig casings for about 6 minutes, and wash the cornstarch with pH=7-7.5 water Clean, then add 133.33g glycerin, 2.67g sodium pyrophosphate, water, and pig casings into the basin, stir evenly, and let stand at a temperature of 15°C for 2 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com