Process for preparing dried casing with ultra large aperture

A technology with super-large caliber and manufacturing technology, which is applied in the field of manufacturing technology of dry casing with controllable caliber, which can solve problems such as casing rupture, waste products, and no dry casing production technology, and achieve the effect of increasing yield and increasing expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below.

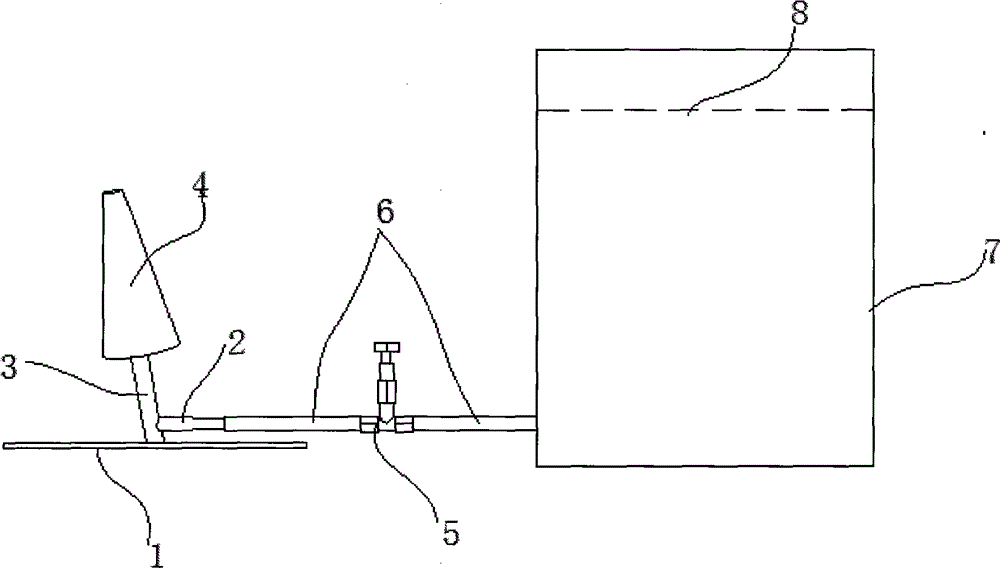

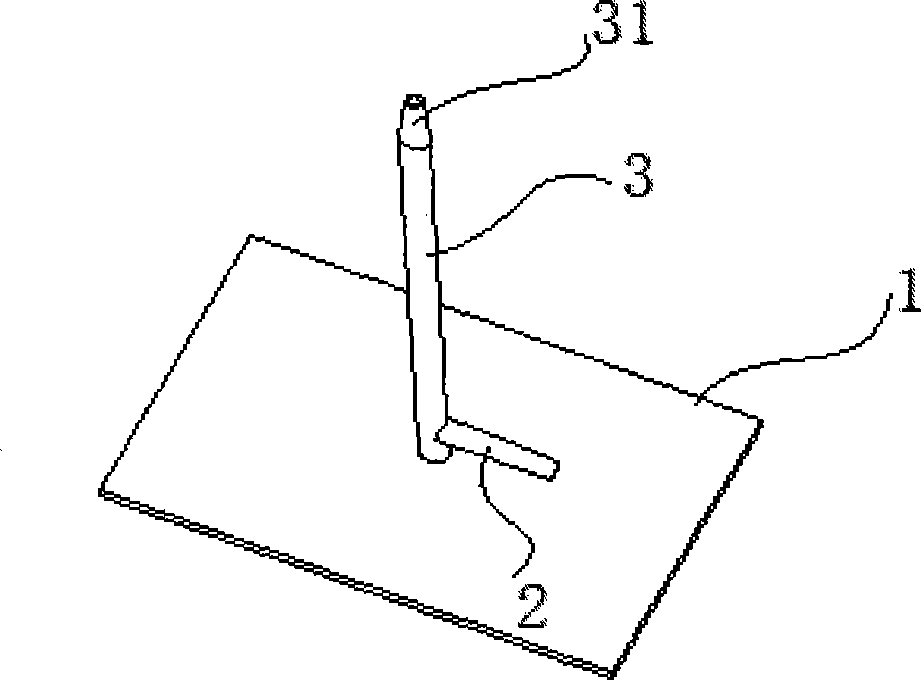

[0022] In order to better implement the present invention, a tapered diameter expander needs to be used, and its structure is as figure 1 figure 2 with 3 Shown:

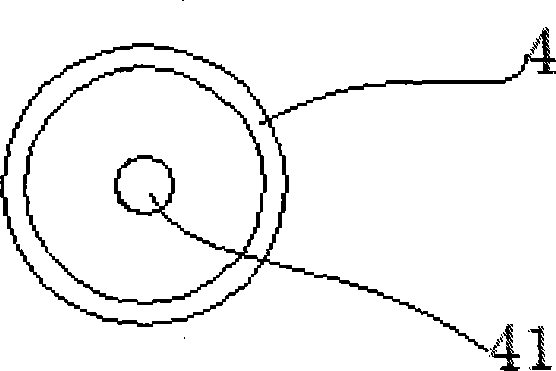

[0023] A frame tube 3 is fixed obliquely on the base 1, a tapered pipe head 31 is reserved on the top of the frame tube 3, and a branch pipe 2 is connected transversely at the bottom. Liquid can enter the frame tube 3 from the branch tube 2. The branch pipe 2 is connected to the liquid storage tank 7 through a conduit 6 and a valve 5 is installed on the branch pipe 6 to control the liquid flow rate. The liquid storage tank 7 stores an acetic acid solution with a pH value of 2 to 3, and the liquid level 8 is higher than the top of the cone-shaped amplification cylinder 4, so that the acid solution can smoothly flow out from the top of the cone-shaped amplification cylinder 4. The cone-shaped amplification cylinder 4 is cone-shaped, the outside is a stainles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com