Casing for maintaining toughness and tenderness of sausage for a long time, preparation method thereof, and prepared sausage

A technology for sausages and casings, which is applied in sausage preparation and food fields. It can solve the problems of sausage research, without involving the maintenance of tenderness and toughness of sausages, and achieve the effect of simple preparation method, easy implementation, and enhanced economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

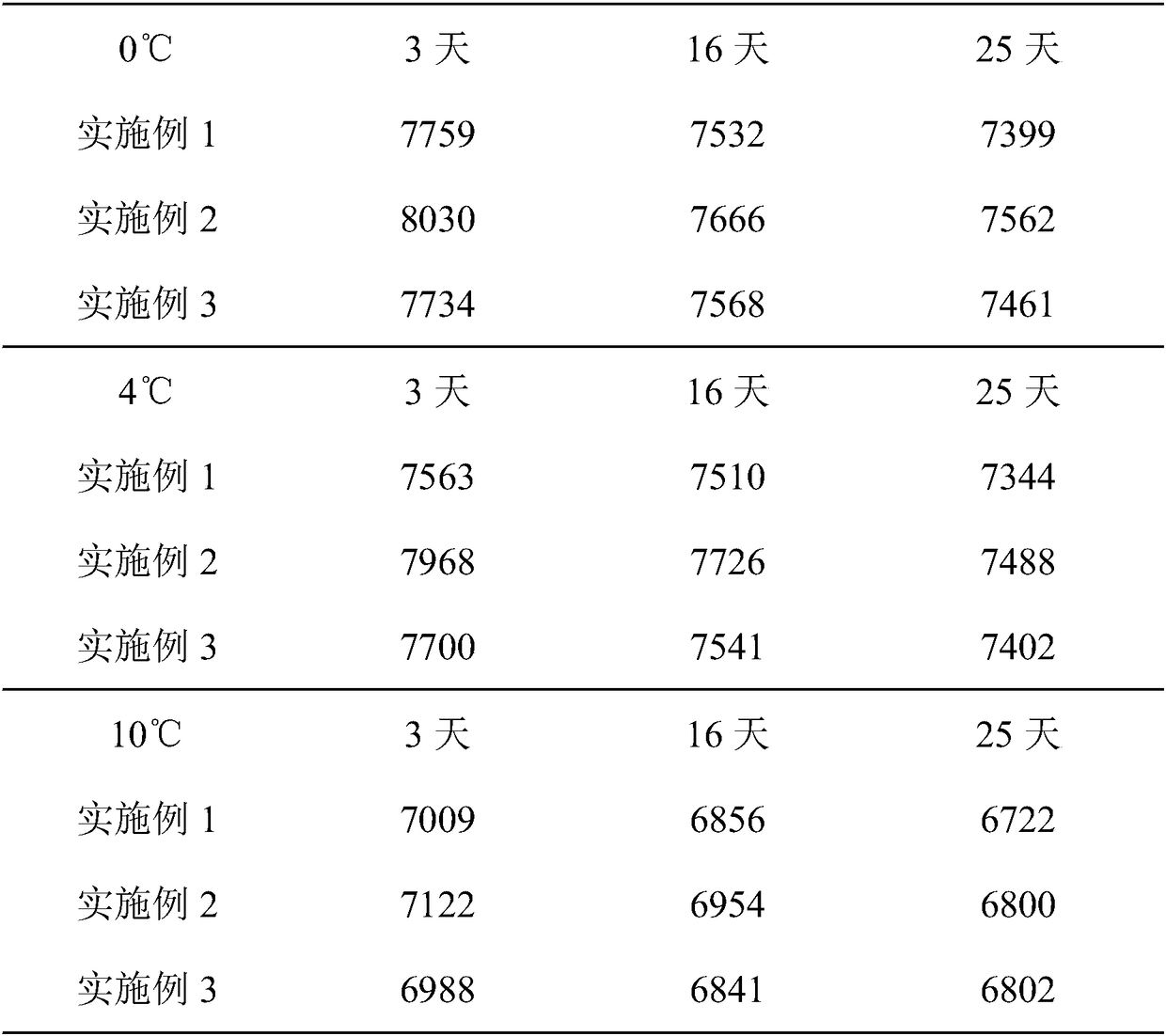

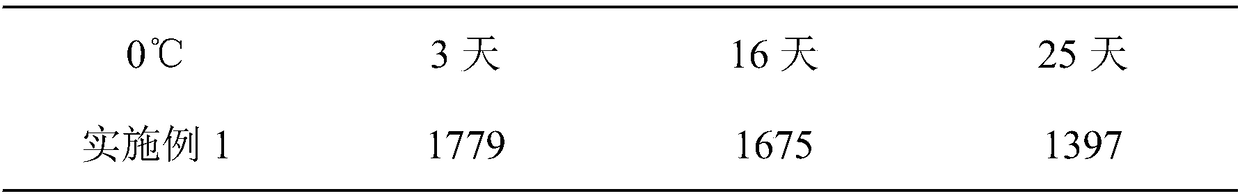

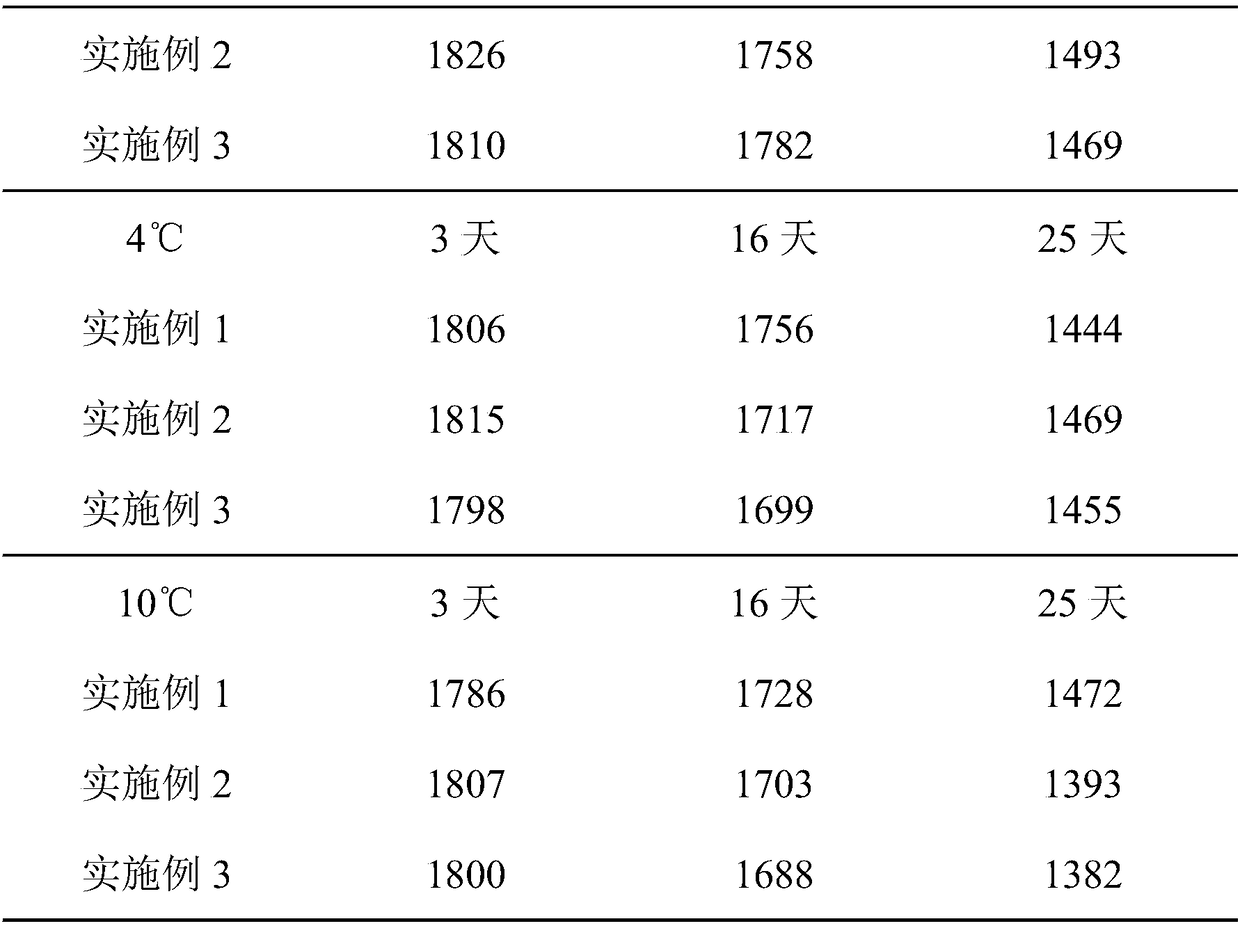

Embodiment 1

[0028] (1) Wash the natural pig casings, and then carry out desalination treatment;

[0029] (2) adding the resultant of step (1) into a mixed solution of soybean lecithin and soybean oil for 70 to 100 minutes;

[0030] (3) Process the product of step (2) with treatment agent A for 40 minutes;

[0031] (4) Treat the product of step (3) with treating agent B for 70 to 100 minutes;

[0032] (5) After drying the product obtained in step (4), immerse it in a ferulic acid solution with a concentration of 1.25wt% for 5 minutes, take it out and air-dry it;

[0033] The treatment agent A is composed of ultrafine microcrystalline cellulose, gallic acid and sodium carboxymethyl cellulose in a weight ratio of 16:0.3:4;

[0034] The treatment agent B is a mixture of lactic acid and NaCl, wherein the concentration of lactic acid is 19.5ml / kg·NaCl.

[0035] The concentration of the soybean lecithin is: in parts by weight, 1 part of soybean lecithin is added to every 27.5 parts of water; ...

Embodiment 2

[0038] (1) Wash the natural pig casings, and then carry out desalination treatment;

[0039] (2) adding the resultant of step (1) into a mixed solution of soybean lecithin and soybean oil for 70 to 100 minutes;

[0040] (3) Process the product of step (2) with treatment agent A for 30 minutes;

[0041] (4) Treat the product of step (3) with treating agent B for 70 minutes;

[0042] (5) After drying the product obtained in step (4), immerse it in a ferulic acid solution with a concentration of 1.2wt% for 2 minutes, take it out and air-dry it;

[0043] The treatment agent A is composed of ultrafine microcrystalline cellulose, gallic acid and sodium carboxymethyl cellulose in a weight ratio of 18:0.2:5;

[0044] The treatment agent B is a mixture of lactic acid and NaCl, wherein the concentration of lactic acid is 19ml / kg·NaCl.

[0045] The concentration of the soybean lecithin is as follows: in parts by weight, 1 part of soybean lecithin is added to every 27 parts of water; t...

Embodiment 3

[0048] (1) Wash the natural pig casings, and then carry out desalination treatment;

[0049] (2) adding the resultant of step (1) into a mixed solution of soybean lecithin and soybean oil for 70 to 100 minutes;

[0050] (3) Process the product of step (2) with treatment agent A for 45 minutes;

[0051] (4) Treat the product of step (3) with treating agent B for 100 minutes;

[0052] (5) After drying the product obtained in step (4), immerse it in a ferulic acid solution with a concentration of 1.5 wt% for 5 minutes, take it out and air-dry it;

[0053] The treatment agent A is composed of ultrafine microcrystalline cellulose, gallic acid and sodium carboxymethyl cellulose in a weight ratio of 15:0.2:2;

[0054] The treatment agent B is a mixture of lactic acid and NaCl, wherein the concentration of lactic acid is 19ml / kg·NaCl.

[0055] The concentration of the soybean lecithin is as follows: in parts by weight, 1 part of soybean lecithin is added to every 32 parts of water;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com