Sausage casing salting apparatus

A technology of sausage casings and rotating gears, which is applied in the direction of sausage casings, sausage casing impregnation, and chemical treatment of natural intestines. It can solve the problems of pig small intestines that cannot be kneaded, the effect of adding salt is poor, and affects production efficiency, so as to prevent salt splashing , high production efficiency and strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

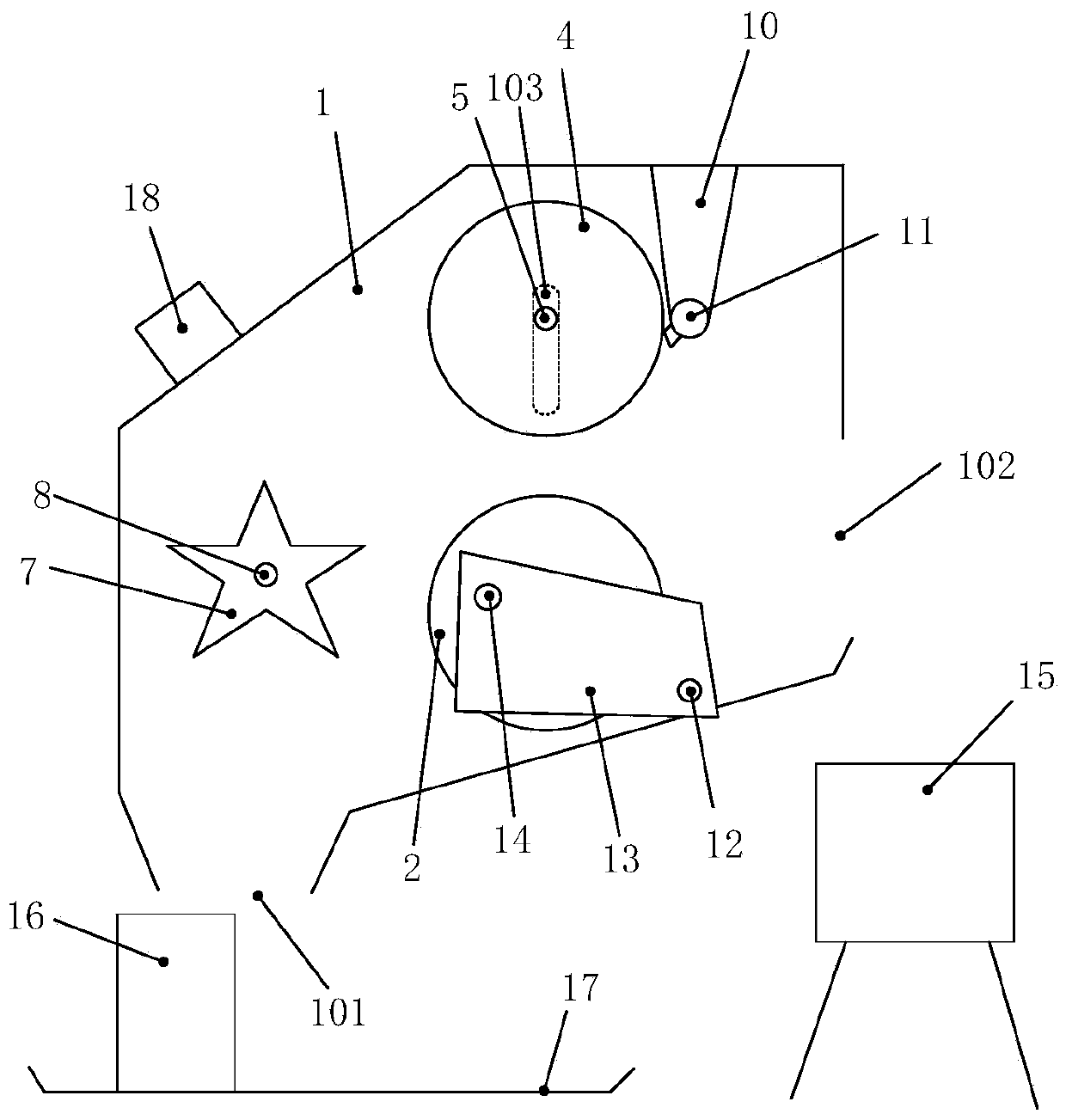

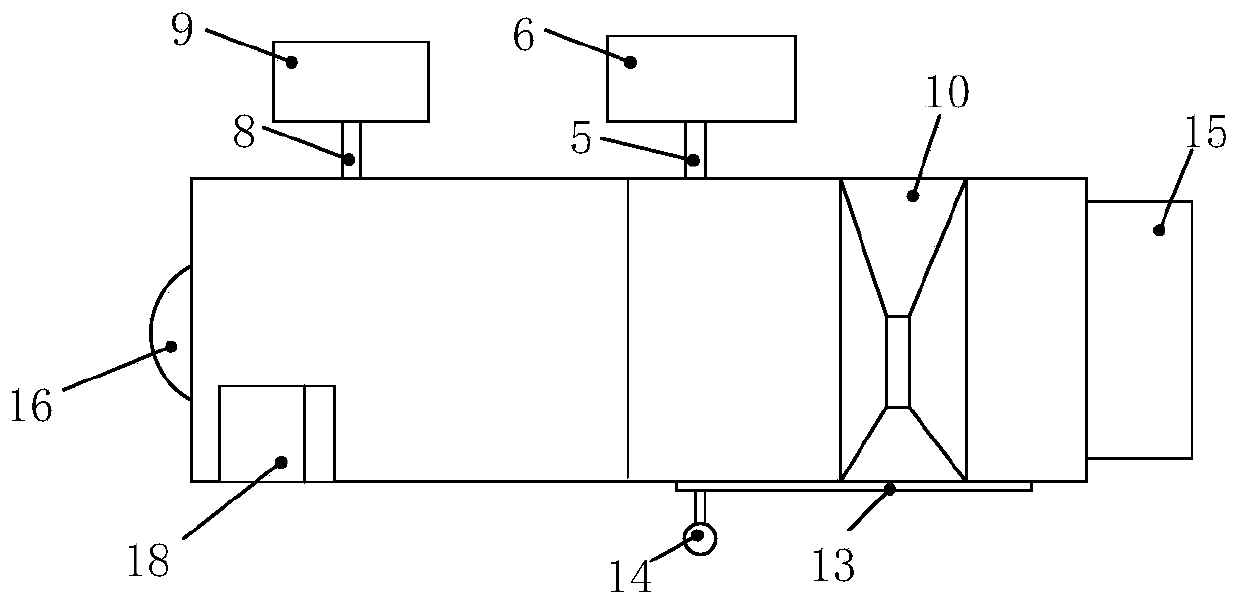

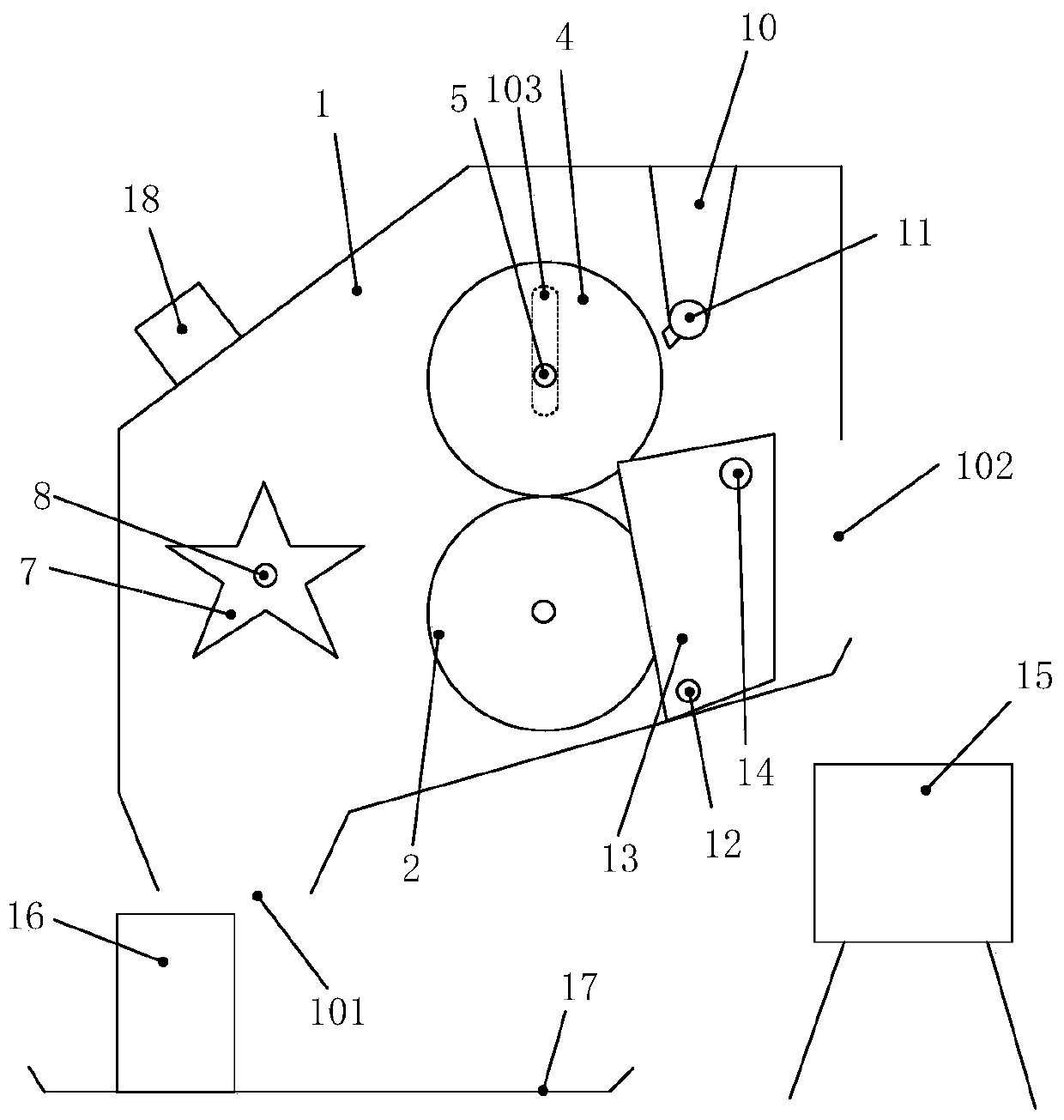

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

[0027] Such as Figure 1~4 As shown, the present embodiment provides a casing salting device, including a protective housing 1, a first rotating gear 2, a first transmission shaft 3, a second rotating gear 4, a second transmission shaft 5, a lifting motor 6, a gear Motor (not shown in the figure), polygonal running wheel 7, the 3rd transmission shaft 8, running wheel motor 9 and funnel 10.

[0028] The upper, lower, left, right and back sides of the protective shell 1 are closed to form a container with an open front. The left and right sides of the protective shell 1 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com