Production line for cellulose sausage casing and production process for cellulose sausage casing

A technology of cellulose casing and production process, which is applied in the direction of cellulose casing, sausage casing, making sausage casing, etc., can solve the problems of poor dimensional stability, low degree of automation, low strength, etc., and achieve high production efficiency and product quality. Stable, good thickness consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

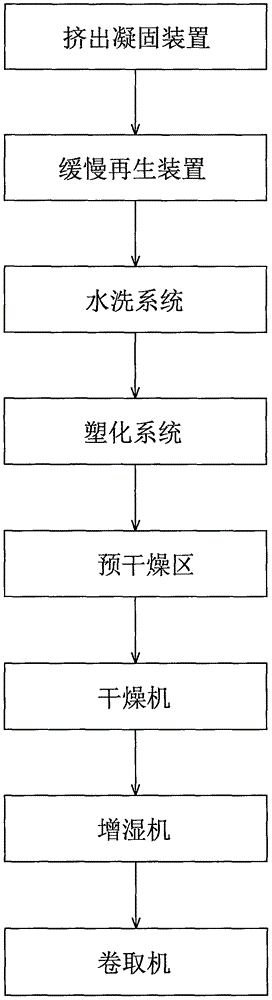

[0028] Such as Figures 1 to 4 As shown, the cellulose casing production line includes extrusion coagulation device, slow regeneration device, water washing system, plasticizing system, drying system, humidifier and coiler

[0029] The drying system includes a pre-drying area and a dryer.

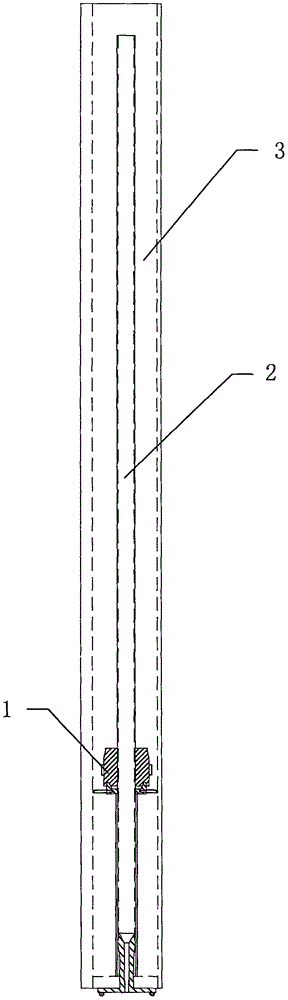

[0030] The extrusion regeneration device includes a nozzle 1 and an acid bath 3 , the nozzle 1 is connected with a mandrel 2 , and the extrusion regeneration device is an extrusion molding area of the cellulose casing 10 .

[0031] The slow regeneration device is an area where casings are slowly regenerated. For the cellulose sleeve produced by the regeneration reaction of the extrusion regeneration device, various indicators are fine-tuned in this area, including the folding diameter of the casing 10, the color and the uniformity of the thickness of the casing 10.

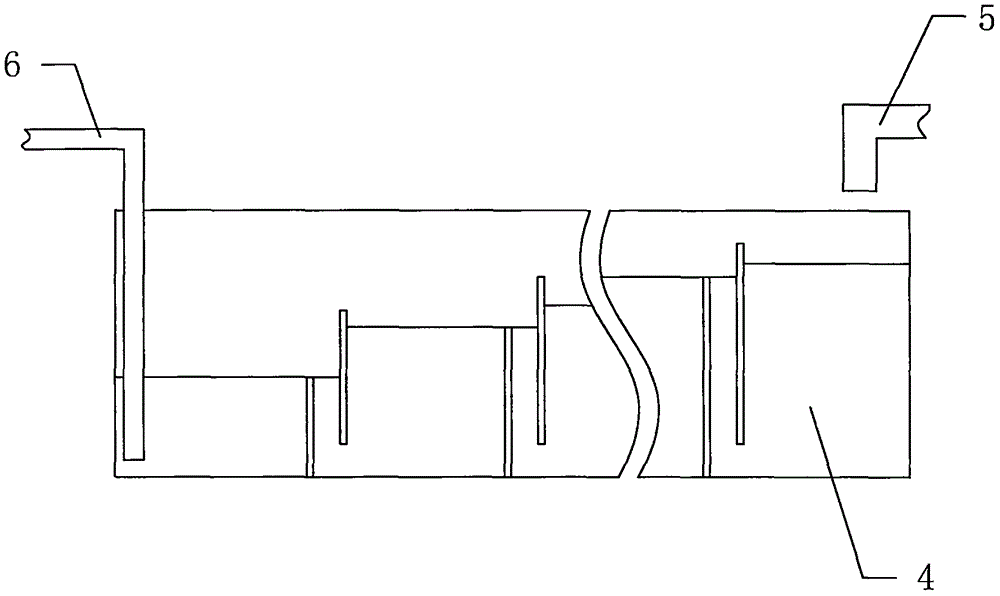

[0032] The water washing system includes a freezing water tank, four pickling tanks 7, ten water washing tanks 4 and a de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com