Production process of boiled/fried collagen casing

A technology of collagen and production technology, which is applied in the direction of fabric casings, sausage casings, and fibrous casings, etc. It can solve the problems of casings sticking to each other, the effect is not obvious, casing shrinkage, etc., and the weak points of casings are reduced, and the color is uniform and beautiful , the effect of increasing the degree of cross-linking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

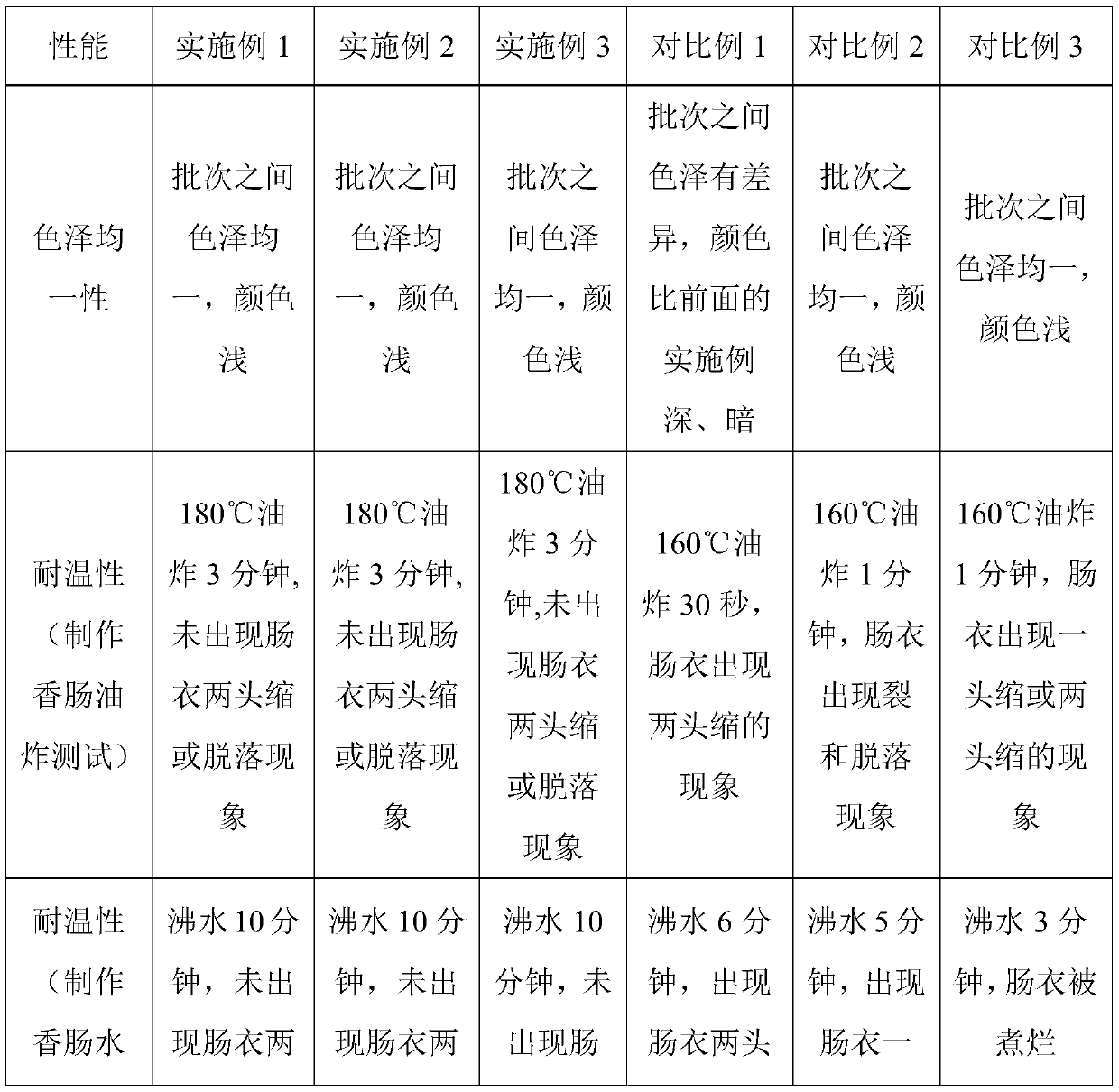

Examples

Embodiment 1

[0023] The production technology of described boiled / fried type collagen sausage casing specifically comprises the following steps:

[0024] (1) Extraction of collagen fibers: purchase cow split skin, cut into small pieces of 15*15cm, wrap in ash, marinate, wash ash, add glycerin, hydrogen peroxide and ferric ion to the semi-finished product after ash washing for pretreatment , acidified, and then washed to remove the fibrous interstitium and retain the collagen fibers. The processed cowhide pieces are then diced and ground to obtain collagen fiber pulp. The mass proportion of added hydrogen peroxide is 0.5%, the mass proportion of small molecule polyol is 0.5%, iron ion 100ppm, measured by the mass of the semi-finished product after ash washing.

[0025] (2) Preparation of collagen clusters: collagen fibers and auxiliary materials are mixed to obtain collagen clusters. The collagen group includes the following raw materials in weight percentage: water 88%, microcrystalline ...

Embodiment 2

[0029] The production technology of described boiled / fried type collagen sausage casing specifically comprises the following steps:

[0030] (1) Extraction of collagen fibers: Purchase cow split skin, cut into small pieces of 15*15cm, marinate in ash, wash ash, add ethylene glycol, sodium hypochlorite and ferric ions to the semi-finished product after ash washing Pretreatment, acidification, and water washing to remove fibrous interstitial and retain collagen fibers. The processed cowhide pieces are then diced and ground to obtain collagen fiber pulp. The mass proportion of added hydrogen peroxide is 5%, the mass proportion of small molecule polyol is 2%, iron ion 1000ppm, measured by the mass of the semi-finished product after ash washing.

[0031] (2) Preparation of collagen clusters: collagen fibers and auxiliary materials are mixed to obtain collagen clusters. The collagen group includes the following raw materials in weight percentage: water 94%, microcrystalline cellul...

Embodiment 3

[0035] The production technology of described boiled / fried type collagen sausage casing specifically comprises the following steps:

[0036] (1) Extraction of collagen fibers: Purchase cow split skin, cut into small pieces of 15*15cm, wrap in ashes, marinate, wash ashes, add mannitol, hydrogen peroxide and ferric ions to the semi-finished products after washing ashes for pretreatment Processed, acidified, and washed to remove fibrous stroma and preserve collagen fibers. The processed cowhide pieces are then diced and ground to obtain collagen fiber pulp. The mass proportion of added hydrogen peroxide is 3%, the mass proportion of small molecular polyol is 5%, iron ion 600ppm, measured by the mass of the semi-finished product after ash washing.

[0037] (2) Preparation of collagen clusters: collagen fibers and auxiliary materials are mixed to obtain collagen clusters. The collagen group includes the following raw materials in weight percentage: water 90%, microcrystalline cel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com