Equipment for producing filmed pipe by filmed strip

一种薄膜管、薄膜带的技术,应用在应用、食物科学、香肠制作等方向,能够解决褶皱彼此粘连等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

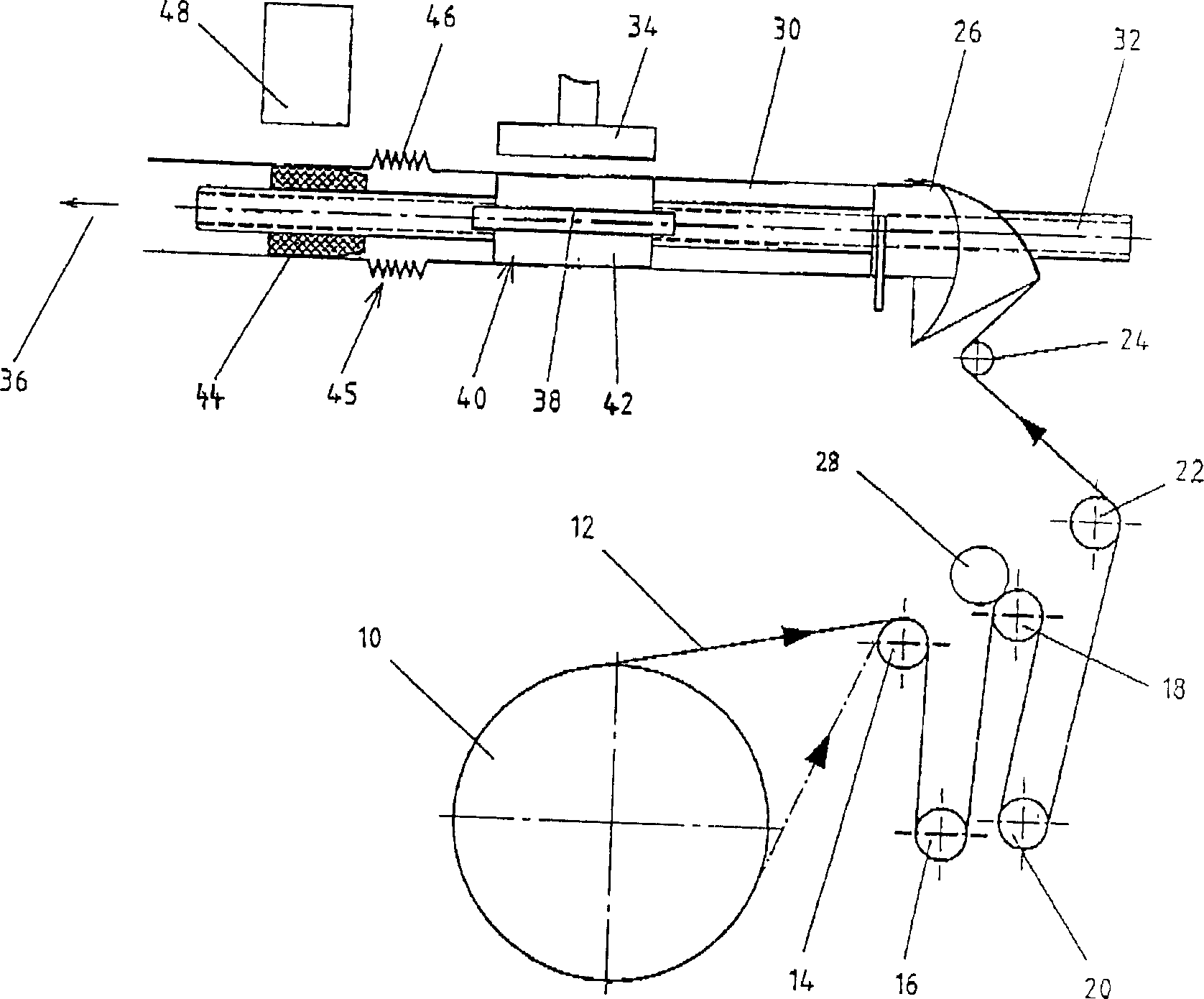

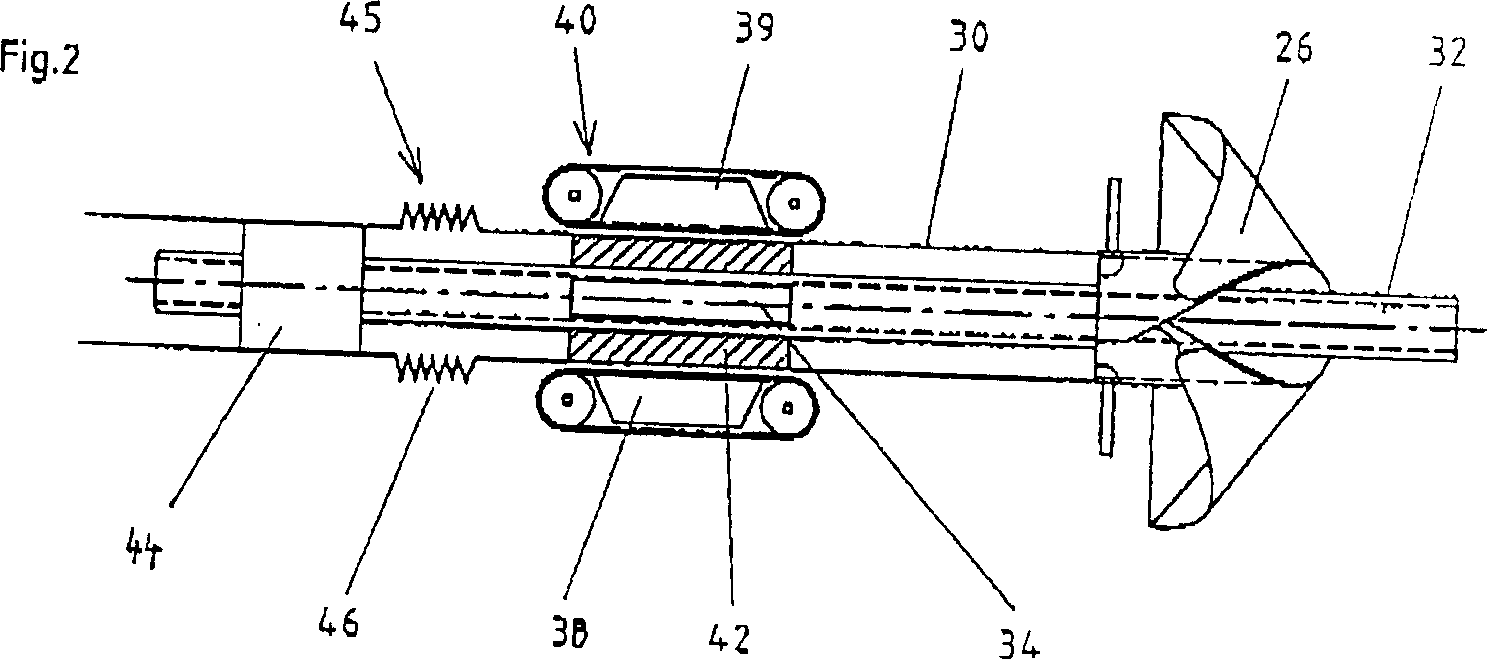

[0023] figure 1 The apparatus shown in has a feed roll 10 of film web 12 which is fed for processing. The web of film 12 is transferred to a forming shoulder 26 by means of redirection rolls 14 , 16 , 18 , 20 , 22 and 24 . In the region of one of the deflection rollers 18 , a counter wheel 28 bears against the surface of the film web 12 opposite the deflection roller 18 . The deflection roller 18 thus forms a support roller for the counting wheel 28 .

[0024] In the forming shoulder 26 the film strip is formed into a film tube 30 by being formed around a filling tube 32 . In this case, membrane tube 30 surrounds fill tube 32 in a substantially coaxial relationship. After the forming operation, the film tube has two adjacent longitudinal edges which are figure 1 is set upwards in the view of , but not shown, and the two edges are sealed or welded at a sealing station 34, which is arranged downstream of the forming shoulder 26 in the filling discharge direction (see arrow 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com