Stabilized meat products

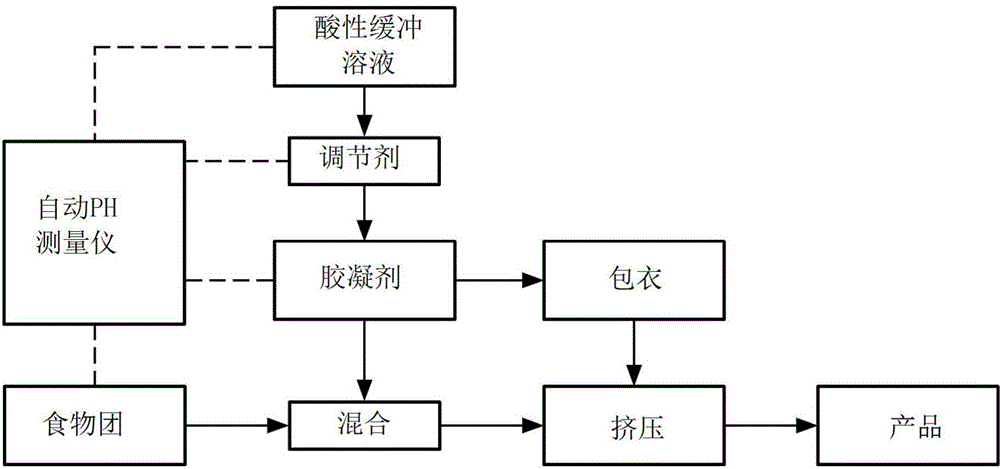

A technology for food and gelling agent, applied in the application field of acid buffer solution in stabilizing food, can solve the problems of equipment corrosion and high salt intake, and achieve the effects of good network structure, good adhesion and good overall texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

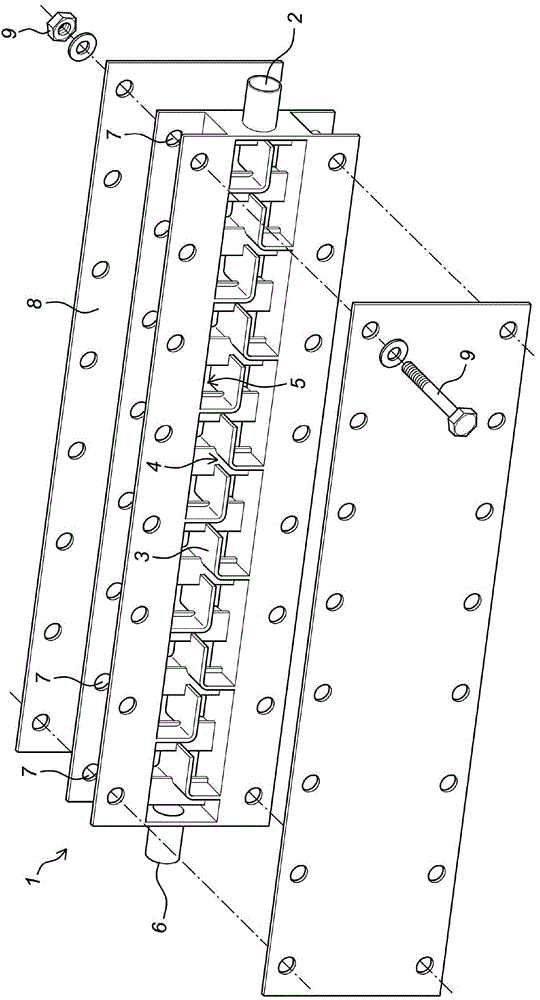

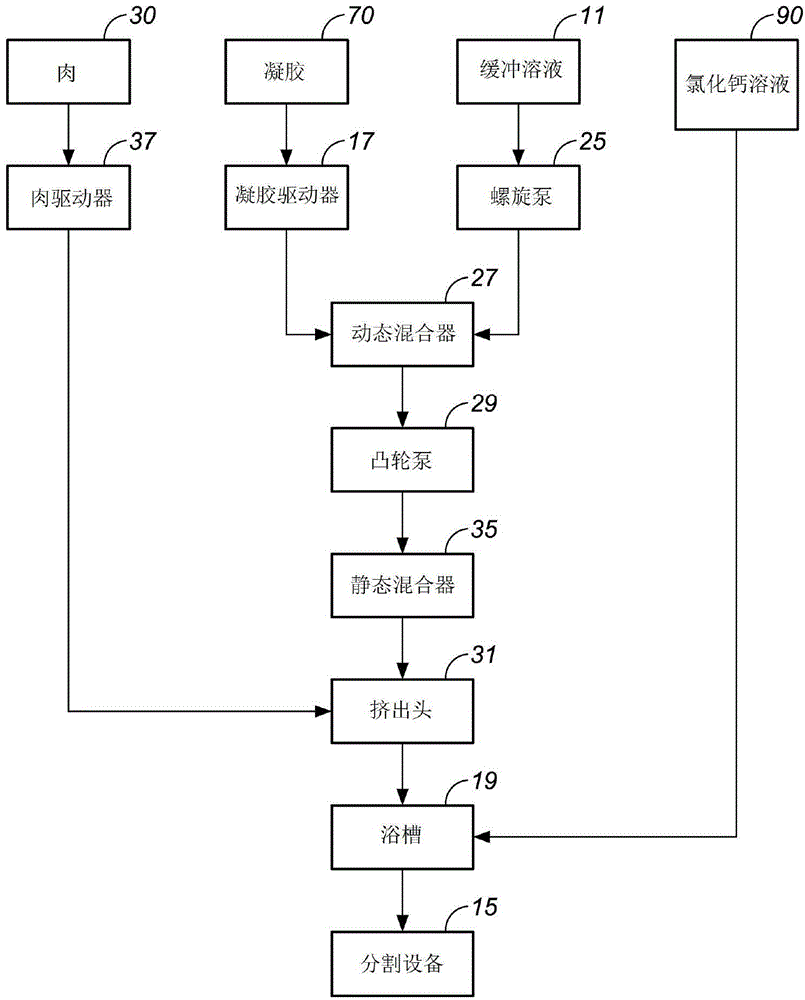

[0097] A 250 mM, pH 3.5 buffer solution containing 38.93 g / kg of citric acid and 19.03 g / kg of sodium citrate and 892.04 g of water was prepared. Blend the mixture with a high-speed blender until both the citric acid and sodium citrate are dissolved. Add 50g / kg of sodium alginate to the mixed solution of water, citric acid and sodium citrate. The mixture was mixed for about 5 minutes to hydrate the sodium alginate. After mixing, the resulting gel is vacuumed to extract as much trapped air as possible, thereby improving squeezability. The produced gel is then co-extruded with the food bolus in order to produce coated food skewers.

Embodiment 2

[0099] A 250 mM, pH 3.5 buffer solution containing 38.93 g / kg of citric acid and 19.03 g / kg of sodium citrate and 877.04 g of water was prepared. Blend the mixture with a high-speed blender until both the citric acid and sodium citrate are dissolved. Add 50g / kg of collagen fibers and mix until the collagen fibers are fully swollen. Add 15g / kg of sodium alginate to the solution of water, citric acid, sodium citrate and collagen fibers that have been mixed. The mixture was mixed for about 5 minutes to hydrate the sodium alginate. After mixing, the resulting gel is vacuumed to extract as much trapped air as possible, thereby improving squeezability. The resulting gel is then co-extruded with the food bolus to produce coated food skewers.

[0100] Figure 7-Figure 9 Shown is the use of a coated gel material comprising phosphate-free meatballs that has not been treated with the acidic buffer solution of the present invention ( Figure 7 ) and the coated gel material comprising...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com