Oiling device

A technology of holding device and oil injection hole, which is applied in sausage casings, slaughtering, making sausage casings, etc. It can solve the problems of affecting smooth feeding and uneven oil film on the surface of casings, and achieves the effects of uniform oiling, simple structure and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

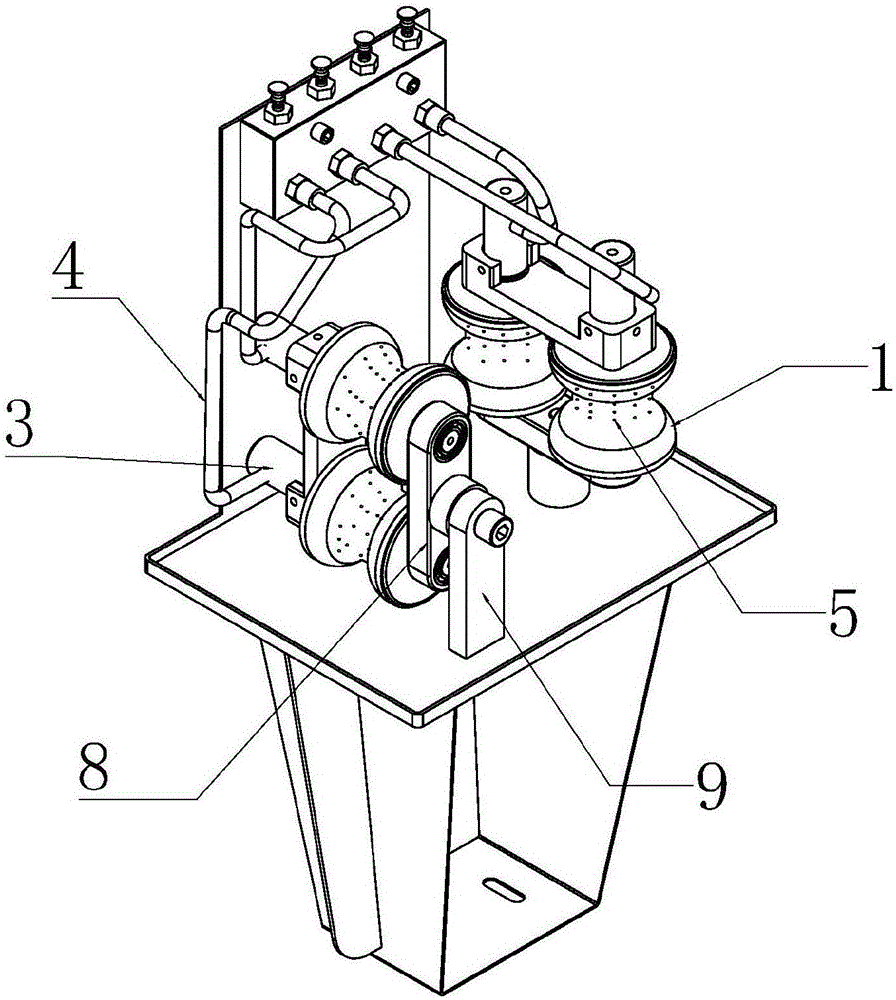

[0017] figure 1 A first embodiment of the oiling device according to the invention is shown. Wherein, the oiling device includes: two pairs of oiling round rollers 1, said oiling round rollers 1 are in the shape of a waist drum with a thin middle and thick ends and are arranged in a manner that can rotate freely around the central rotation axis. The oil roller has a hollow oil injection hole on the central rotation axis. One end of the oil injection hole is closed, and the other end is connected to the oil inlet pipe 4 through the rotary joint 3, and the oil injection hole is evenly distributed on the outer wall circumference of each oil roller 1. A number of micropores 5 communicating with the oil injection holes are distributed; an oil-smearing material layer (not shown), the oil-smearing material layer is made of a material (preferably sponge or gauze) that absorbs and smears oil, and wraps On the outer wall of the oiled round roller 1; the roller holding device, the rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com