Punching and milling all-in-one machine

An all-in-one, punching and milling technology, applied in metal processing equipment, perforation tools, manufacturing tools, etc., can solve the problems of cumbersome processing process, low efficiency, high labor cost, reduce safety hazards, improve flexibility, and improve processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

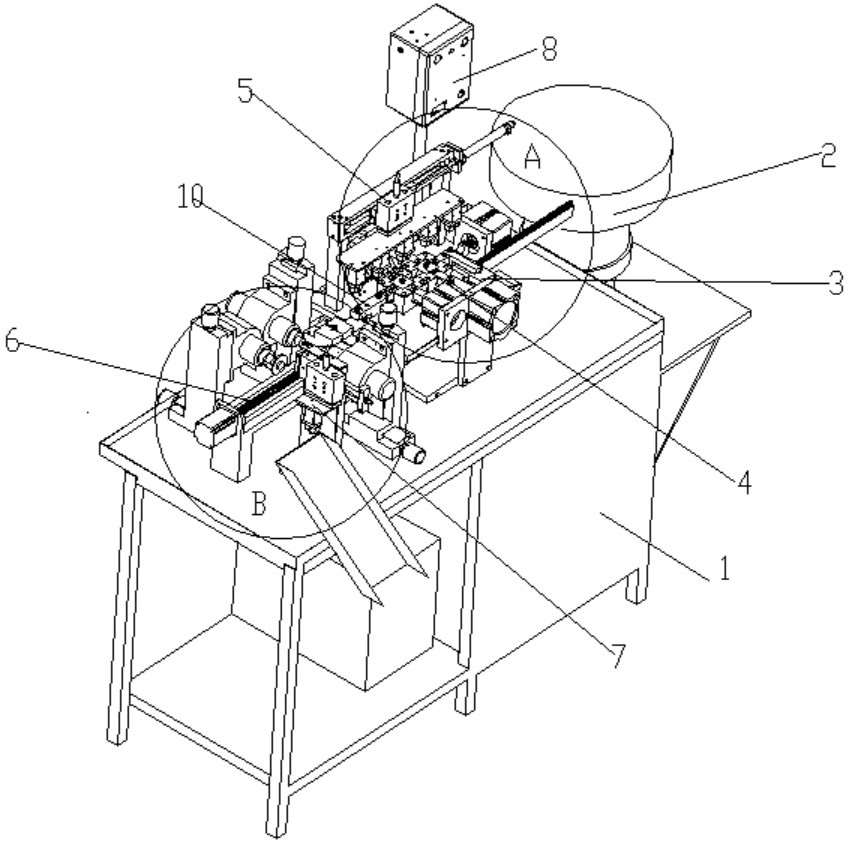

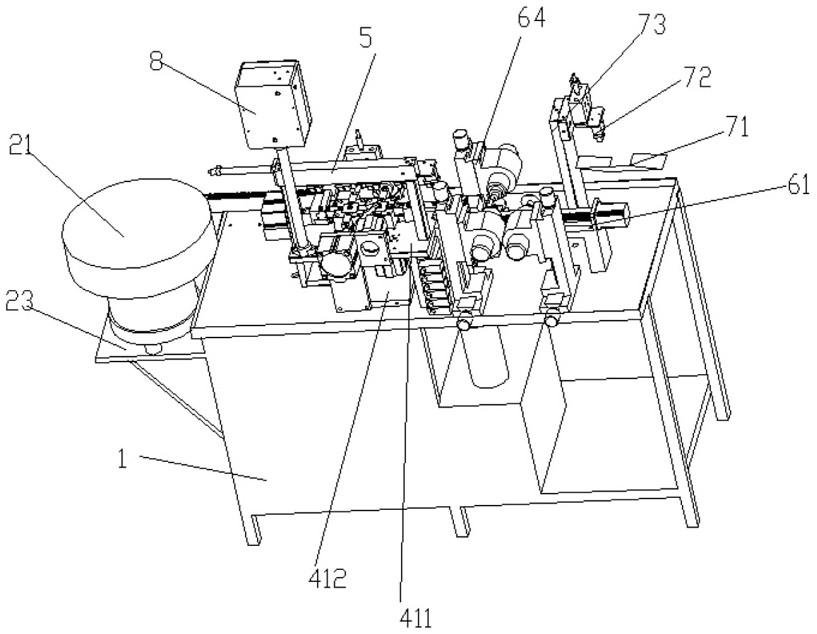

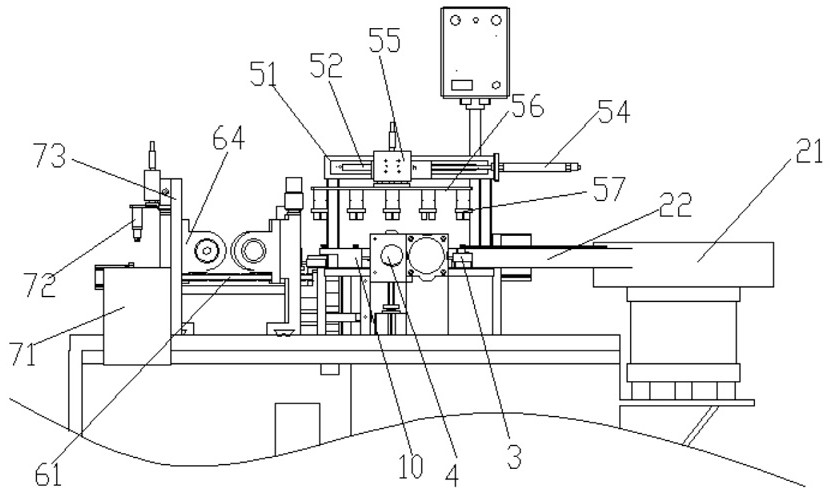

[0050] refer to Figure 8-9 , an integrated punching and milling machine disclosed by the present invention, the specific structure includes a cabinet 1, a vibrating feeding mechanism 2 installed on the cabinet, a moving material receiving mechanism 3, a multi-directional punching mechanism 4, a moving clamping mechanism 5, The multi-station milling mechanism 6, the unloading mechanism 7 and the electric control box 8, the vibrating feeding mechanism vibratingly feeds the parts, and sends the parts to be processed to the mobile material receiving mechanism through the feeding channel, and the mobile material receiving mechanism will The accessories are sent to the clamping and feeding position, the moving clamping mechanism clamps and sends the accessories to be processed to the multi-directional punching mechanism for punching, and then the moving clamping mechanism transfers the punched accessories to the multi-station milling mechanism for multi-station milling. The milling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com