Drilling/grinding integrated combined tool

A combined cutting tool and hole grinding technology, which is applied in drilling/drilling equipment, drilling tool accessories, drilling repair, etc., can solve the problems of low processing efficiency, component failure, high scrap rate, etc., and achieve convenient production, improve processing efficiency, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

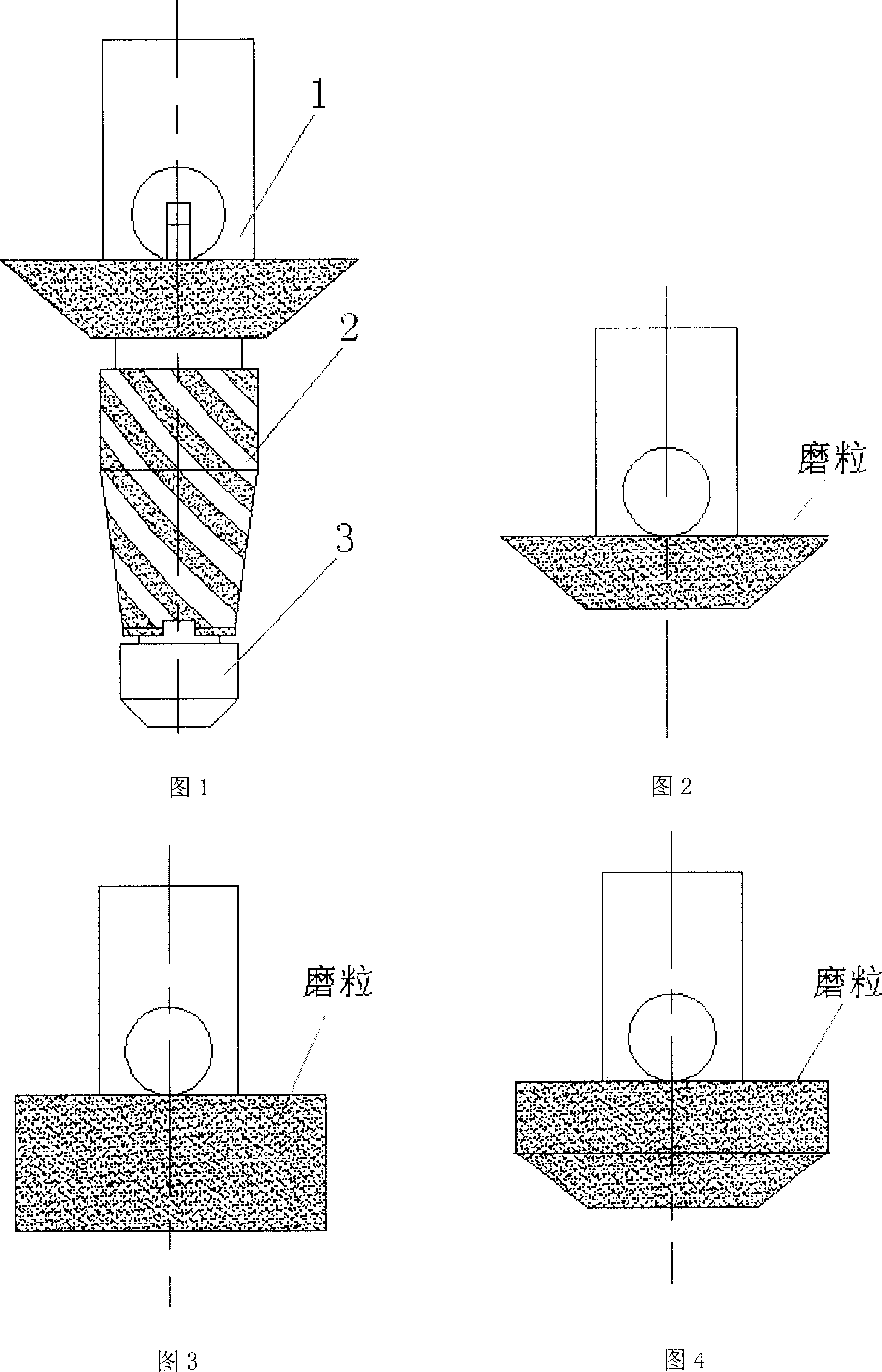

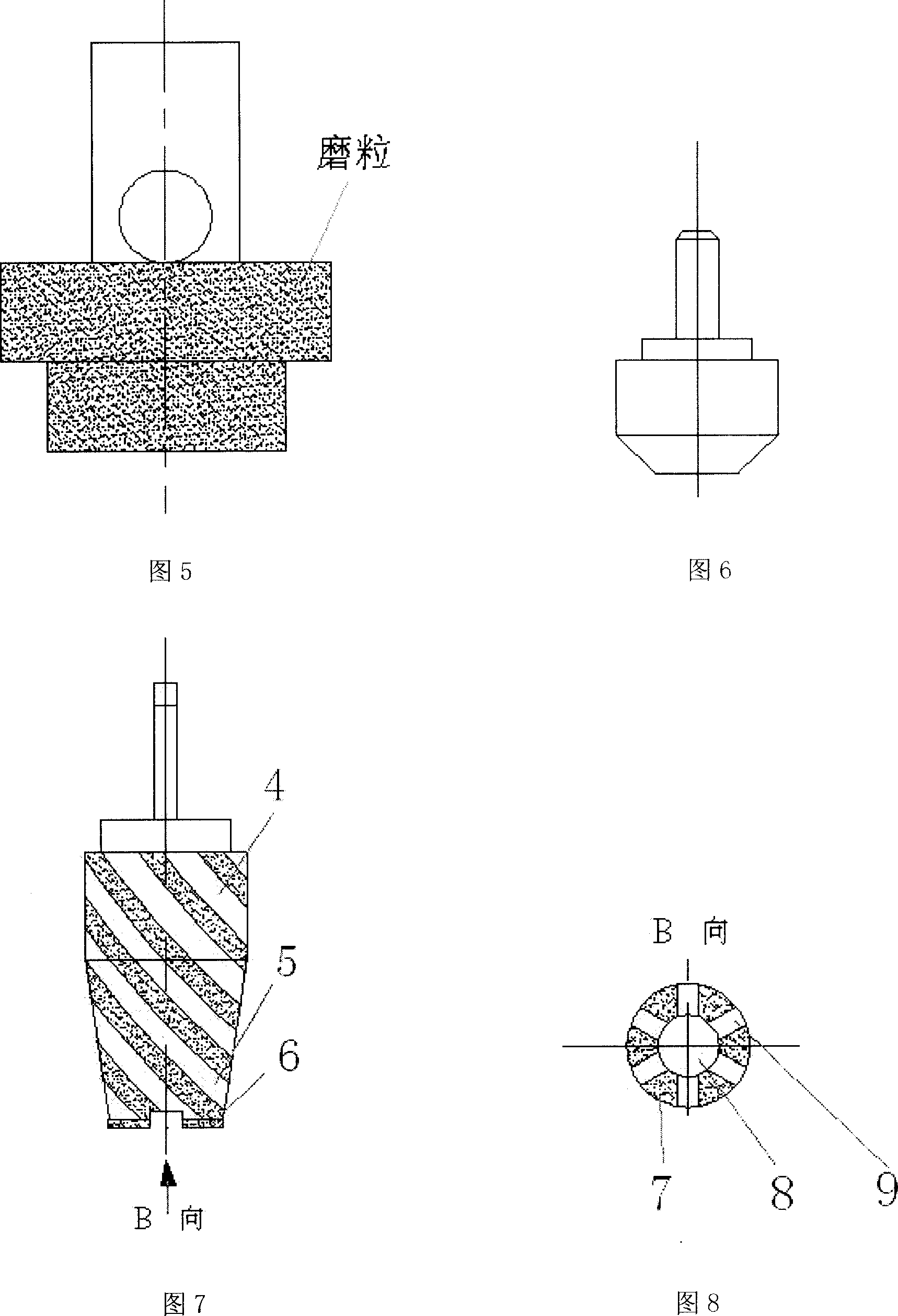

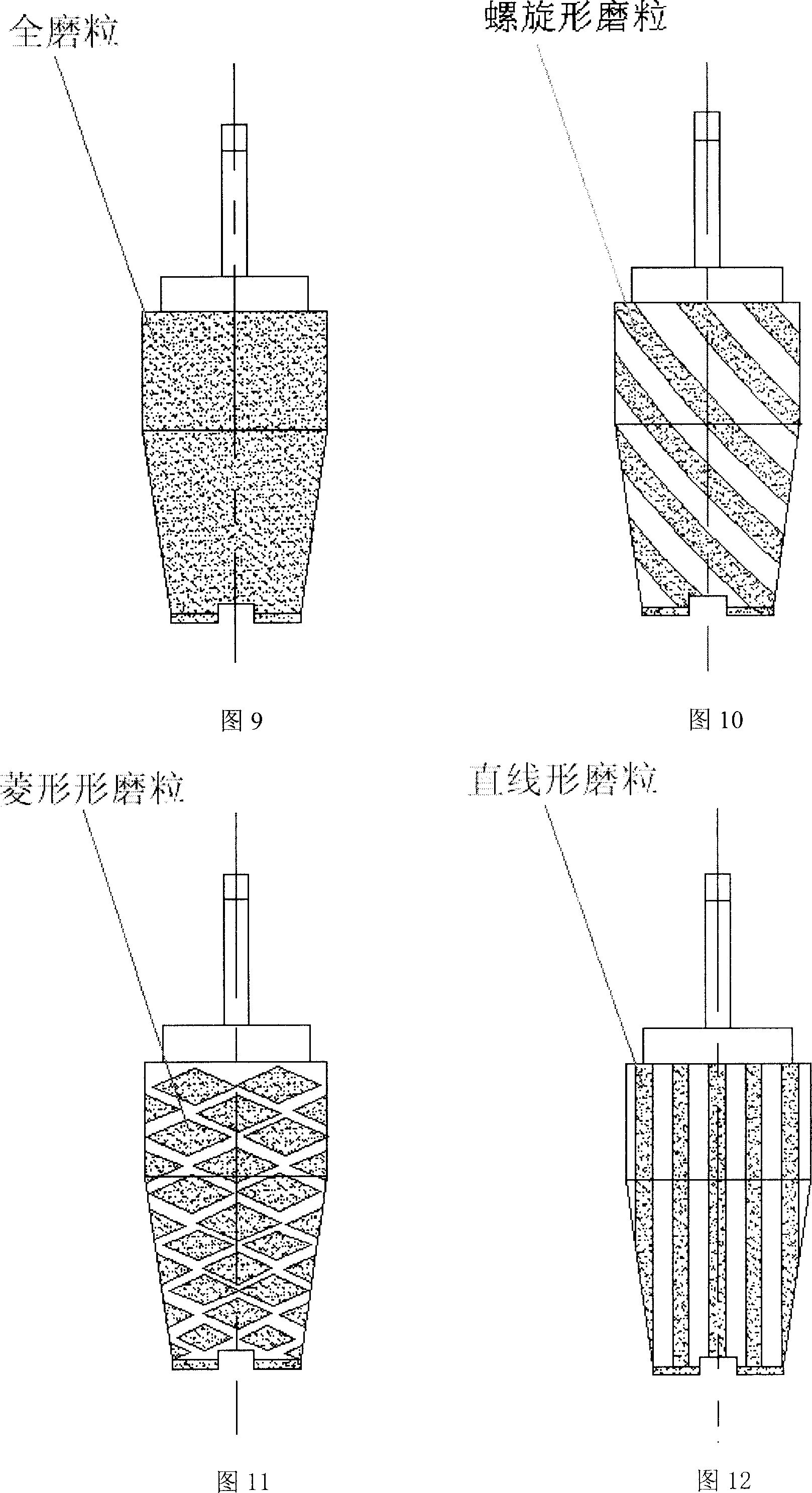

[0032]Figure 1 shows a drilling / grinding integrated combination tool, and the base of the tool is made of metal material. Countersinking countersunk hole section 1 and reaming hole section 2 are connected by taper fit, reaming hole section 2 and guide head 3 are connected by cylinder fit, and the abrasive grains on the tool surface are electroplated (brazing process, bonded abrasive can also be used sintering process, bonding process, etc.), the abrasive grains of the cone part of the expanded grinding hole section 2 are coarse-grained abrasive grains, and the cylindrical part is fine-grained abrasive grains, so as to achieve the purpose of integrating rough and fine machining. The abrasive grains on the surface of the drill bit 2 The shape of electroplating is full abrasive grain, spiral, diamond, straight line, circular, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com