Automatic centering core-taking fresh lotus seed processing all-in-one machine

A technology of fresh lotus seeds and an all-in-one machine, which is applied to fruit core removal devices, shell removal, pod removal, etc., can solve the problems of low production efficiency and high production cost, and achieve the effects of light structure, low production cost, and guaranteed processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

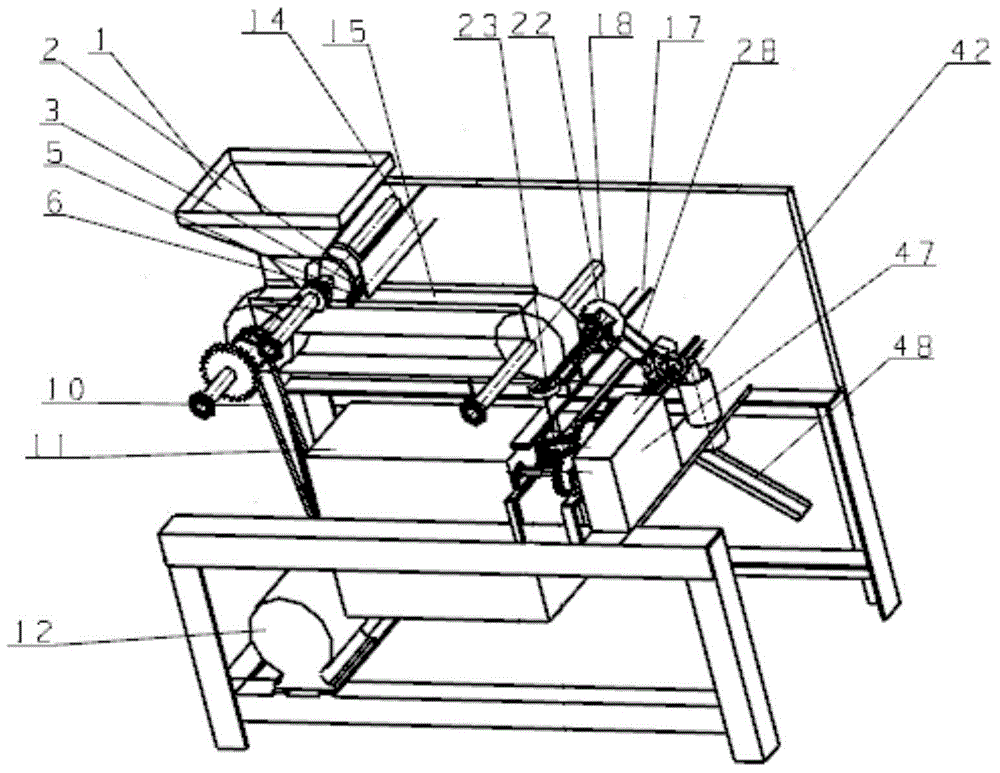

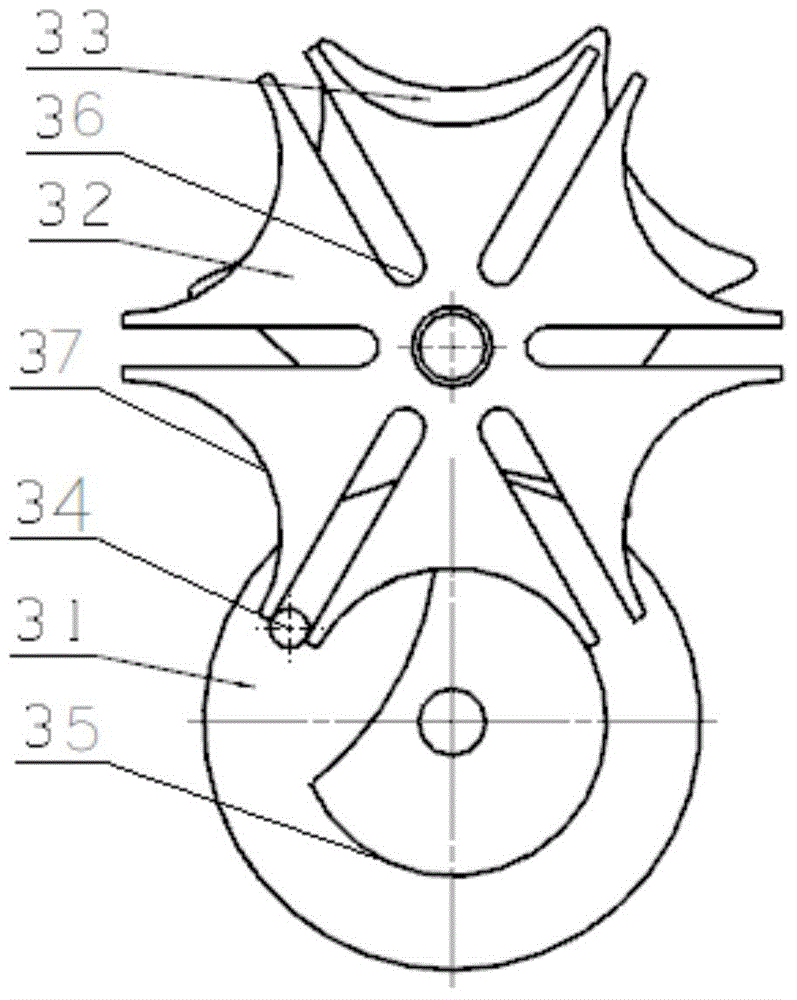

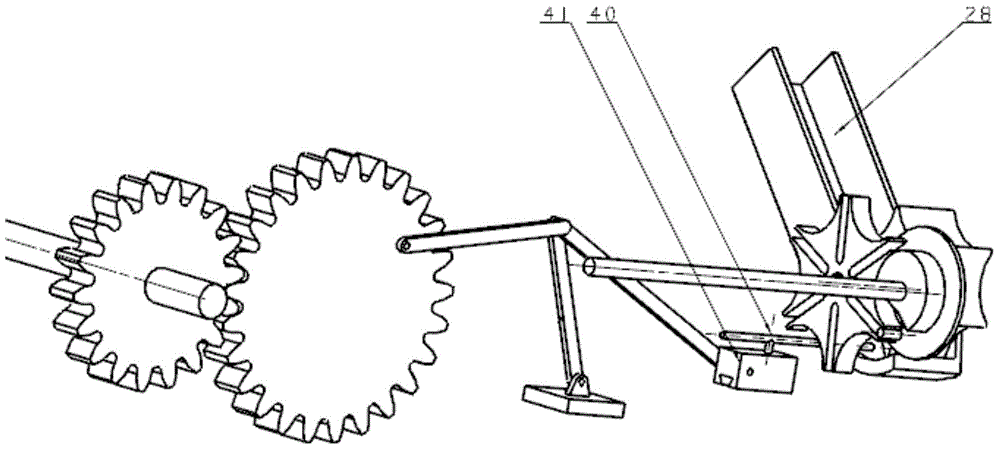

[0031] Such as figure 1 As shown, a fresh lotus seed processing integrated machine for automatic centering and coring includes a transmission mechanism, a shelling mechanism, a centering coring mechanism and a film removal mechanism arranged in sequence. Centering coring mechanism and includes inclined sliding box 28, the sheave device that is arranged on the inclined sliding box 28 below, the second slide block 41, the coring needle tube 40 that is installed on the second slide block 41 and with the second slide block 41 Connected transmission device, the sheave device includes a driving dial 31, a driven sheave 32 and a six-leaf positioning wheel 33 on the same axis as the coring needle tube 40, and a round pin is arranged on the driving dial 31 and the outer flange 35, the driven sheave 32 is provided with a radial groove 36 and an inner concave edge 37, when the round pin on the driving dial 31 does not enter the radial groove 36 of the driven sheave 32, from The inner co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com