Controllable deformable soft cutter

A tool and tool holder technology, applied in the field of controllable deformation soft tools, can solve the problems of surface scratches, workpiece size errors, lack of surface conformity, etc., and achieve the effect of improving processing efficiency and improving grinding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

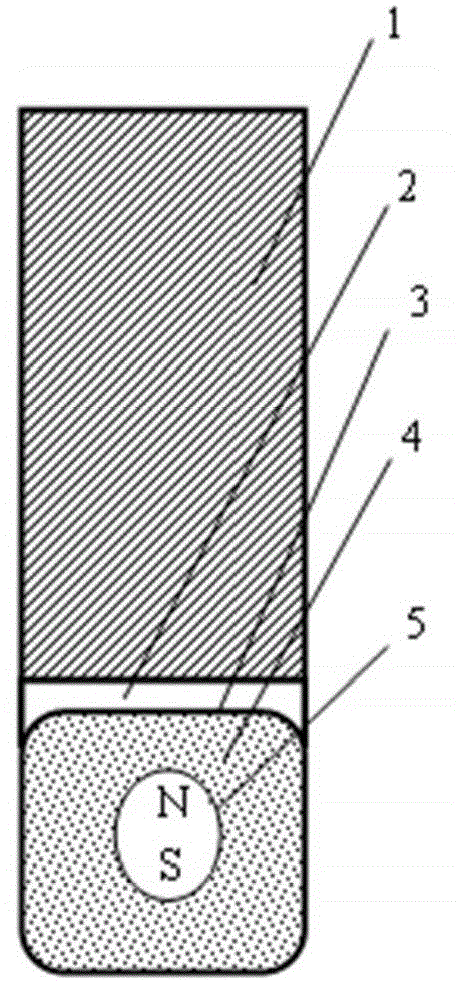

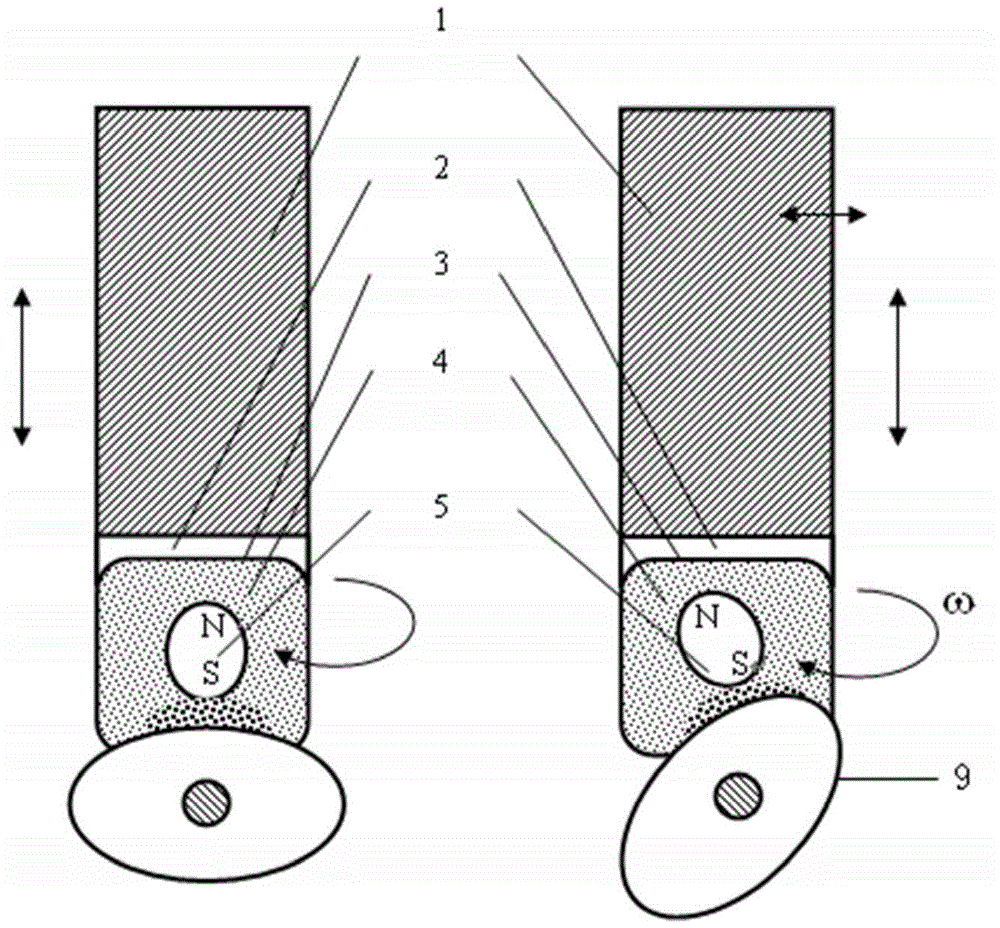

[0046] This embodiment provides a controllable deformable soft tool, including a handle, a functional accessory, and a deformable cutter head, and the deformable cutter head is connected to the handle through a functional accessory; wherein, the deformable cutter head It includes: a sealed and deformed soft shell and a deformation medium arranged inside the sealed and deformed soft shell. The controllable deformable soft tool is connected to the machine tool through the tool handle, and the machine tool drives the tool handle to move, thereby deforming the deformation medium inside the sealed and deformed soft shell, thereby prompting the sealed and deformed soft shell to generate processing force.

[0047] Further, in this embodiment, the deformable cutter head may also include a deformable medium activator mechanism, and the deformable medium activator mechanism interacts with the deformable medium to cause greater deformation of the deformable medium, thereby deforming the s...

Embodiment 2

[0057] Embodiment 2 is a modification example of Embodiment 1.

[0058] The mechanism of action of this embodiment and component parts and action process are identical with embodiment 1, as Figure 5 shown. In order to increase the processing effect of large-surface shell workpieces, the deformation medium actuator can be placed outside the sealed deformation soft shell to form an external deformation medium actuator, and the workpiece is placed between the external deformation medium actuator and the seal between deformed soft shells, such as image 3 shown.

[0059] In this embodiment, deformable medium actuators can also be placed inside and outside the sealed and deformed soft shell, that is, the built-in deformed medium actuator arranged inside the sealed and deformed soft shell and the built-in deformed medium actuator set outside the sealed and deformed soft shell The external deformation medium actuator together constitute the deformation medium actuator mechanism, ...

Embodiment 3

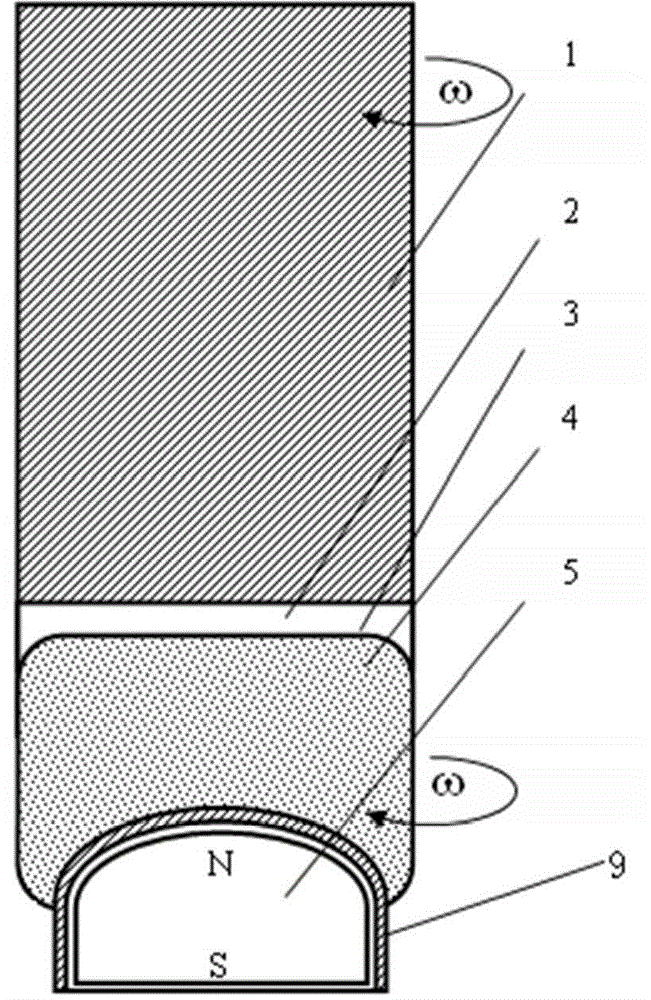

[0061] Embodiment 3 is a variation of Embodiment 2.

[0062] The action mechanism, components and action process of this embodiment are the same as those of Embodiment 2. In order to increase the magnetic field excitation effect of the deformation medium actuator mechanism, a bearing rotating body is added to the external deformation medium actuator, and the bearing rotating body is a rotating shaft or a ball hinge, such as Figure 6 As shown in the figure, the magnetic pole of the external deformable medium exciter moves with the controllable deformable soft tool through the action of the magnetic field force, so as to achieve a higher efficiency of light under the condition that the magnetic pole of the external deformable medium exciter is always excited by a strong magnetic field. The whole processing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com