Precision finishing method of inner spherical surface of high-purity aluminum thin-wall part

A thin-walled part and precision machining technology, applied in the precision machining field of the inner spherical surface of high-purity aluminum thin-walled parts, can solve the problems of difficult processing of high-purity aluminum thin-walled parts, difficult to meet the requirements of high surface quality of inner spherical surface, etc. Improve deformation and vibration, meet design and use requirements, and overcome the effect of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

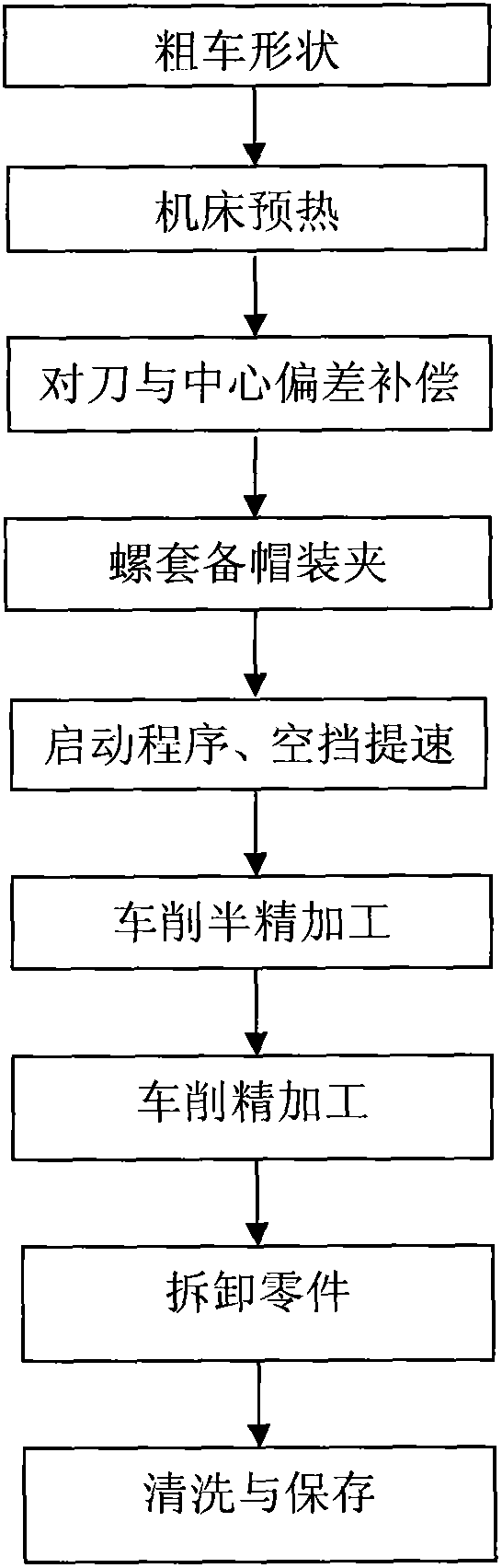

[0048] The present invention will be further described below by means of specific embodiments:

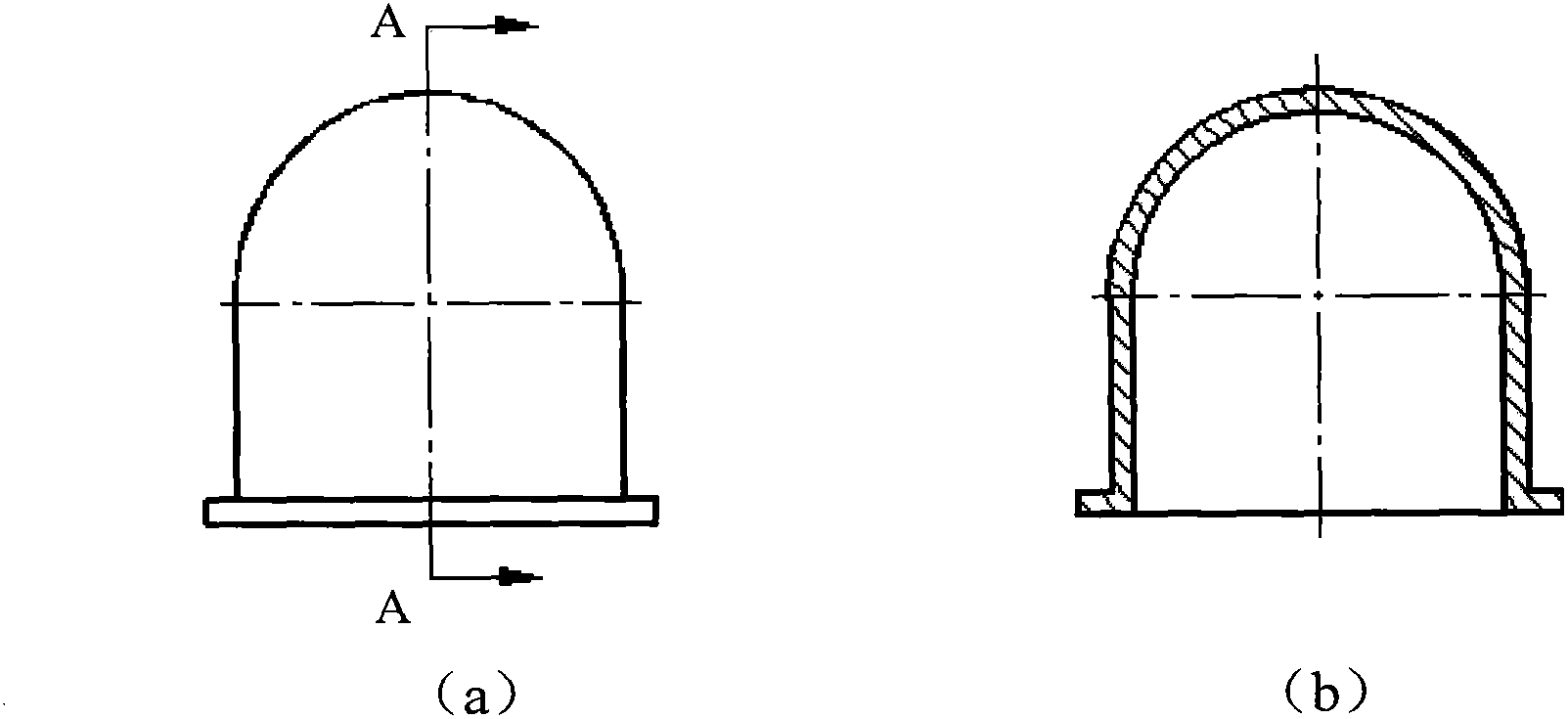

[0049] see figure 2 ,in, figure 2 (a) is a top view of a high-purity aluminum part 3 in a preferred embodiment of the processing method of high-purity aluminum precision parts of the present invention, figure 2 (b) is figure 2 (a) Cross-sectional view. In this embodiment, the high-purity aluminum part 3 is a thin-walled part, one end is spherical, the size is small, the length is 22mm, the diameter of the inner spherical surface is φ20mm, the diameter of the outer spherical surface is φ23.2mm, the wall thickness is 1.6mm, and the outer edge of the orifice is thicker. 1.2mm, width 3.4mm, high-purity aluminum parts 3 require that the verticality between the straight wall of the orifice and the outer bottom annular end surface is required to be 0.01mm, and the design requirement for the inner surface finish is Ra0.05. In order to achieve a better light reflection effect, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com