Electromagnetic T-shaped beam vibration energy harvester on basis of rigid and flexible combined structure

A vibration energy collection, rigid-flexible technology, applied in electrical components, electromechanical devices, etc., can solve the problem of high resonance frequency, extend the effective length of the beam, and achieve the effect of wireless power supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

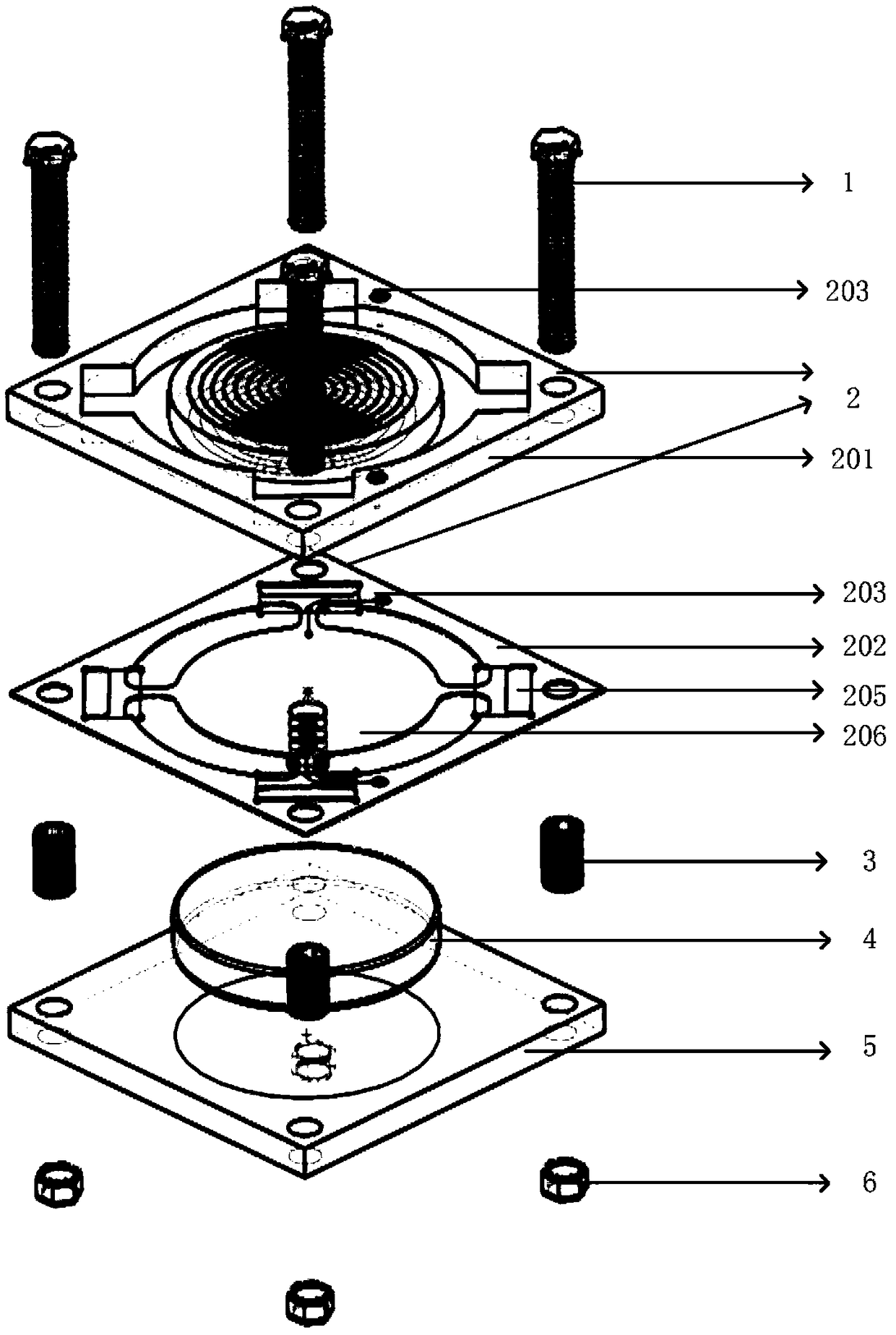

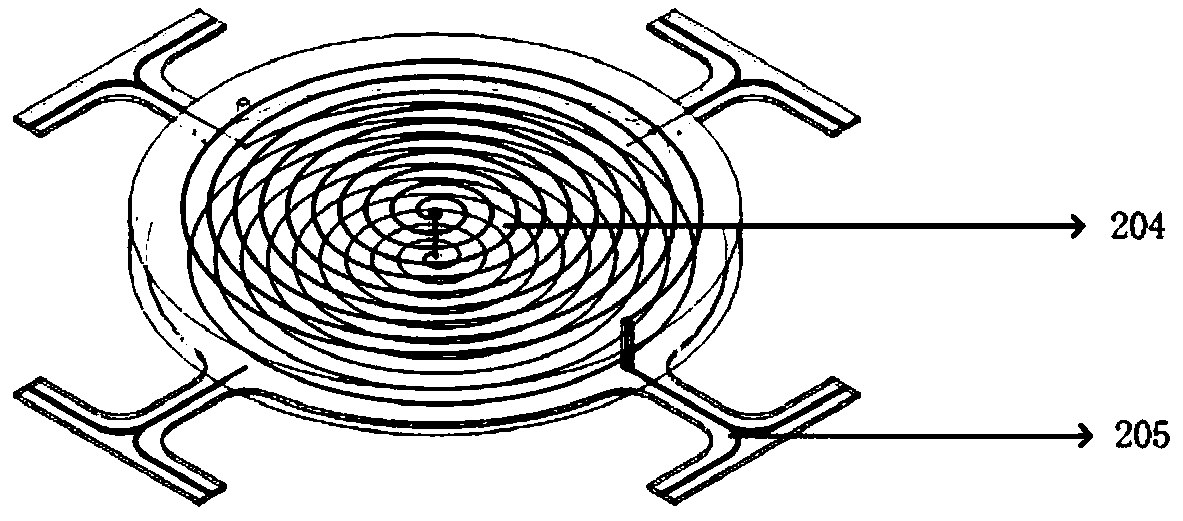

[0024] The present invention provides an electromagnetic T-beam vibration energy harvester based on a rigid-flexible structure, the structure of which is as follows: figure 1 As shown, it includes screw 1, rigid-flex board 2, magnet 4, copper pillar 3, rigid support board 5 and nut 6. Wherein, the rigid-flex board 2 includes a rigid board 201 , a flexible board 202 , a conductive hole 203 , a coil 204 , a T-beam 205 and a pickup piece 206 . The specific structure of the coil in the board is as follows figure 2 As shown, the center of the top coil and the bottom coil are connected by a via hole, and the two coils should be wound in opposite directions during design, so as to ensure that the induced electromotive force generated by the two coils is in the same direction. Both ends of the coil are connected to the flexible board through via holes, and finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com