Belt leather piece and production method thereof

A belt and leather sheet technology, applied in the field of belt leather sheet and its preparation, can solve the problems of large temperature change response, waste of raw materials, easy stickiness of leather edge oil, etc., and achieves difficult separation, low production cost, and improved elasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

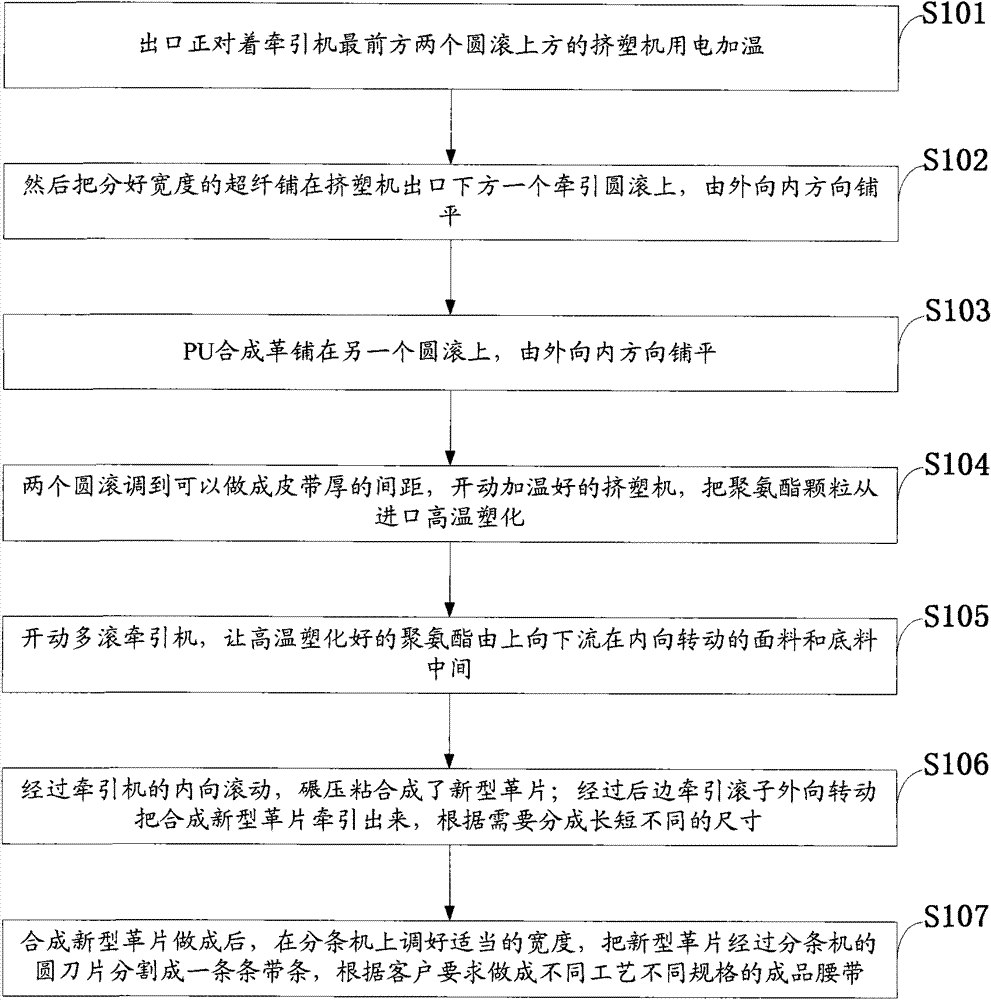

[0029] The preparation method of the belt leather sheet according to the embodiment of the present invention, the preparation method of the belt leather sheet comprises the following steps:

[0030] Step 1: First heat the barrel of the extruder with an electric heating ring; from about 150 degrees at the inlet to about 200 degrees at the outlet;

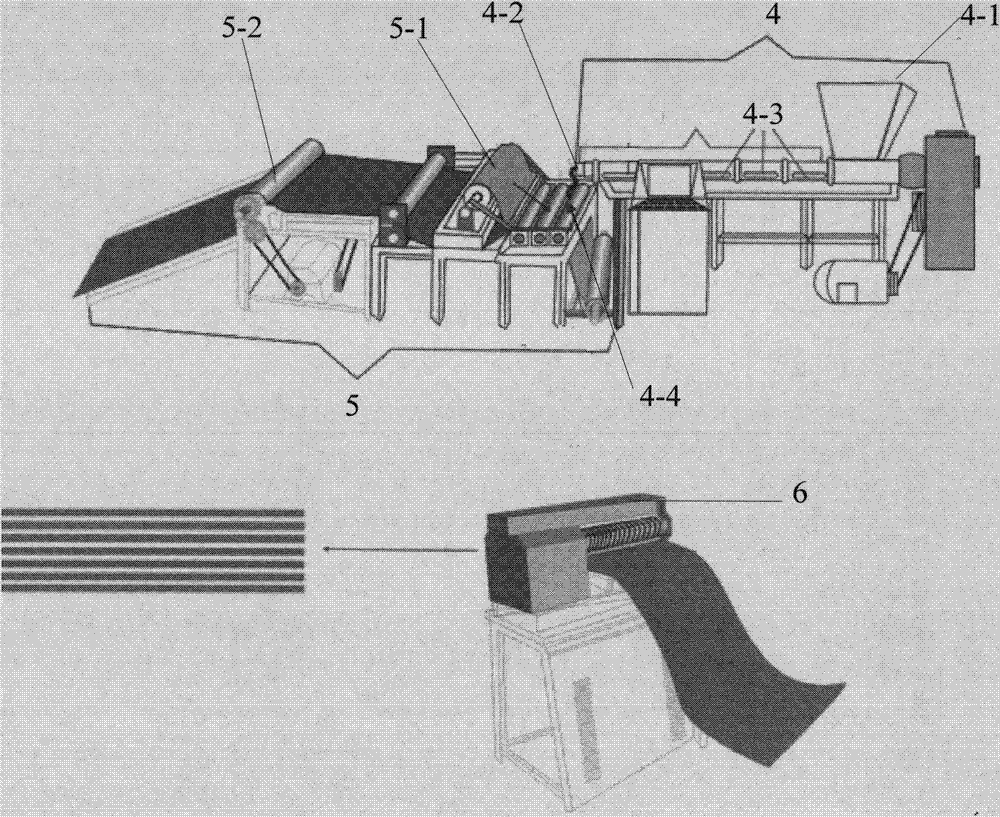

[0031] Step 2: Then spread the slit width microfiber roll head on one of the three traction forming rollers under the exit of the extruder, and spread it from the outside to the inside; the microfiber roll is worn on the multi-roll traction forming On the rolling frame of the machine, it must be able to rotate in circles. When making a belt, the superfiber rolled up to the feed port of the multi-roll tractor should not be too loose, and there must be a certain amount of backward pulling force according to the situation.

[0032] Step 3: Lay the head of the PU synthetic leather roll with the cut width on another round roll under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com