Production method of current collector, current collector and secondary battery

A current collector and battery technology, which is applied in the manufacture of secondary batteries, battery electrodes, electrode carriers/current collectors, etc., can solve the problem of difficult control of the density of the electrodeposited layer or electroplating layer, easy fall-off of the electrolyte soaked, and difficulty in stable and continuous production and other issues to achieve the effect of low cost, small investment and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

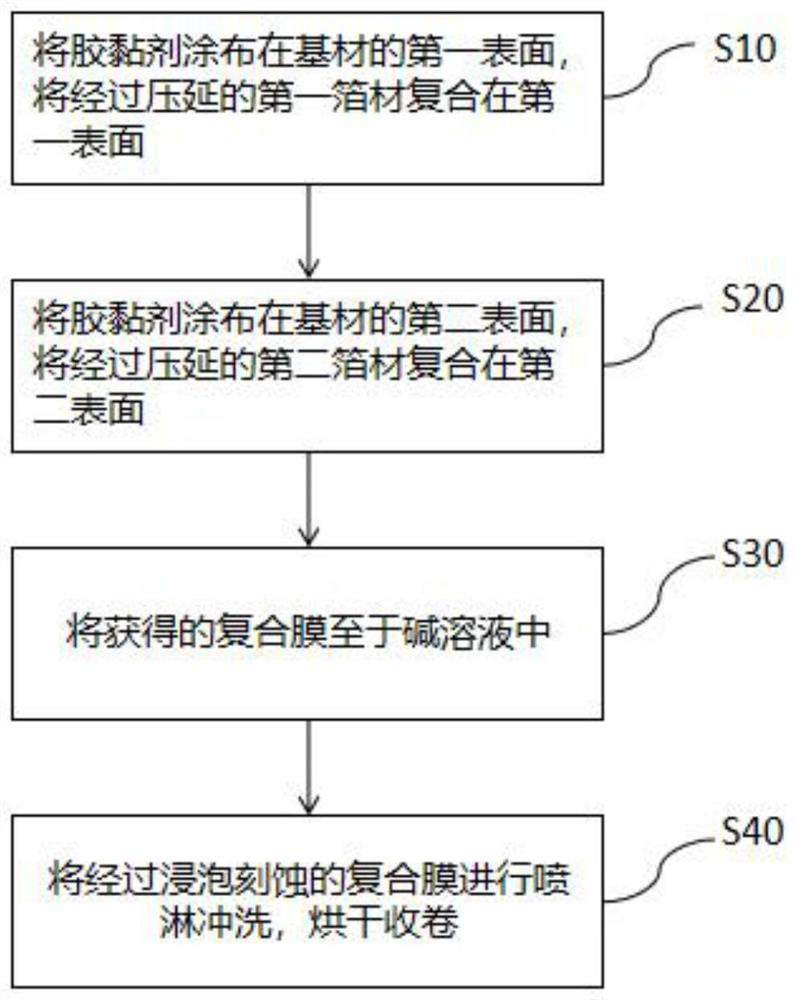

[0034] figure 1 A preparation method of a current collector in the present application is shown. Such as figure 1 Shown, described current collector preparation method comprises the following steps:

[0035] S10, one-time compounding; coating the adhesive on the first surface of the substrate, and compounding the rolled first foil on the first surface;

[0036] S20, secondary compounding: coating the adhesive on the second surface of the substrate, and compounding the calendered second foil on the second surface;

[0037] S30. Soaking and etching: immersing the composite film obtained through the primary composite and secondary composite steps in an alkaline solution;

[0038] S40, spraying and drying: spraying and rinsing the soaked and etched composite film, drying and winding.

[0039] In the above technical solution, the present application uses an adhesive to compound the calendered first and second foils on both sides of the substrate, and then thins the first and se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com