Preparation method of high-safety lithium-ion battery separator

A lithium-ion battery, high-safety technology, applied in the preparation of lithium-ion battery diaphragm, the preparation of high thermal stability battery diaphragm, high mechanical strength, can solve the problems of low safety, high price of high temperature resistant polymers, etc., to improve The effect of strength, mild process conditions, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

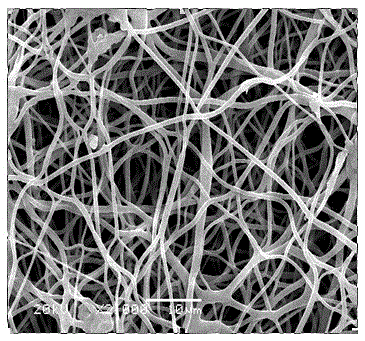

Image

Examples

Embodiment 1

[0030] Example 1: Dissolve 1 mol of 1,2',3,3'-benzophenone tetracarboxylic dianhydride, 0.5 mol of m-phenylenediamine and 0.5 mol of 4,4'-diaminobiphenyl in N,N-dimethyl Among the acetamides, the mass of N,N-dimethylacetamide is 1,2',3,3'-benzophenone tetracarboxylic dianhydride, m-phenylenediamine and 4,4'-diaminobis 10 times the total mass of benzene, and the dissolution temperature is 50°C to obtain a precursor solution. The prepared precursor solution is injected into a syringe in a high-voltage electrospinning device, and a metal needle is assembled on the syringe, and the metal needle is connected to one pole of a high-voltage power supply. Install the cylinder wrapped in aluminum foil on the receiving device, set the spinning parameters as: bias voltage 10kV, working distance 8cm, feed speed 50uL / h, and start electrospinning. After spinning, a white polyamic acid oriented film can be obtained. Take out the aluminum foil covering the polyamic acid film, put it in a dry...

Embodiment 2

[0031]Example 2: Dissolve 1mol2,2',3,3'-biphenyltetracarboxylic dianhydride and 1mol2,4-diaminotoluene in N,N-dimethylacetamide, N,N-dimethyl The mass of acetamide is 20 times of the total mass of 2,2',3,3'-biphenyltetracarboxylic dianhydride and 2,4-diaminotoluene, and the dissolution temperature is 15°C to obtain a precursor solution. The prepared precursor solution is injected into a syringe in a high-voltage electrospinning device, and a metal needle is assembled on the syringe, and the metal needle is connected to one pole of a high-voltage power supply. Install the cylinder wrapped in aluminum foil on the receiving device, set the spinning parameters as: bias voltage 15kV, working distance 8cm, feed speed 800uL / h, and start electrospinning. After spinning, a white polyamic acid oriented film can be obtained. Take out the aluminum foil covering the polyamic acid film, put it in a drying oven and gradually raise the temperature for imidization. The heating method is: keep...

Embodiment 3

[0032] Example 3: Dissolve 1mol of 1,2',3,3'-benzophenone tetracarboxylic dianhydride and 1mol of m-phenylenediamine in N,N-dimethylacetamide, N,N-dimethyl The mass of acetamide is 10-20 times of the total mass of 1,2',3,3'-benzophenone tetracarboxylic dianhydride and m-phenylenediamine, and the dissolution temperature is 30° C. to obtain a precursor solution. The prepared precursor solution is injected into a syringe in a high-voltage electrospinning device, and a metal needle is assembled on the syringe, and the metal needle is connected to one pole of a high-voltage power supply. Install the cylinder wrapped in aluminum foil on the receiving device, set the spinning parameters as follows: bias voltage 15kV, working distance 20cm, feed speed 600uL / h, and start electrospinning. After spinning, a white polyamic acid oriented film can be obtained. Take out the aluminum foil covering the polyamic acid film, put it in a drying oven and gradually raise the temperature for imidiza...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com