Method for modifying titanium-based laser cladding coating through LaB6

A laser cladding and modification technology, applied in the coating, metal material coating process, etc., can solve the problems of uneven distribution, poor wetting and bonding, etc., achieve uniform second phase particles, and reduce residual stress of the coating The degree of concentration and the effect of reducing the grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

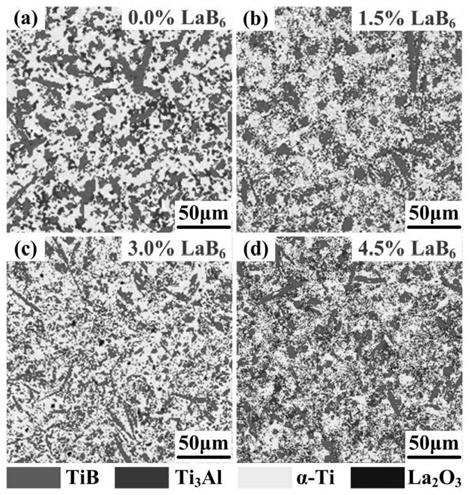

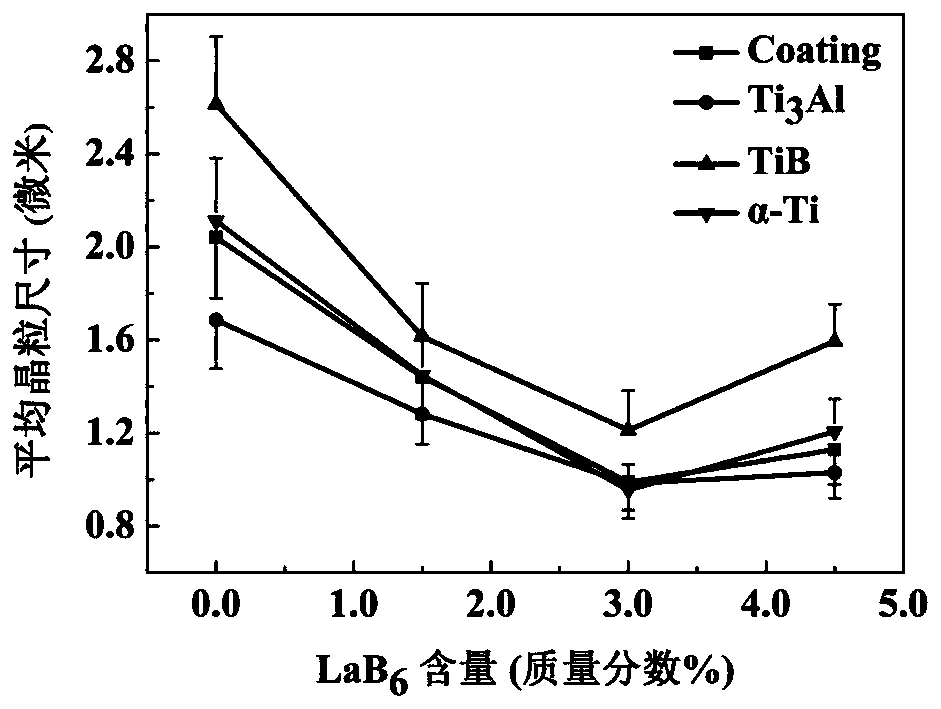

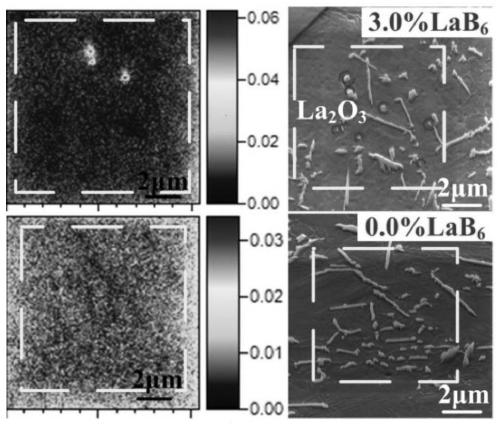

Embodiment 1

[0035] LaB 6 pre-added in Ti+AlB 2 Laser cladding powder, LaB 6 3% by mass, AlB 2 The mass percentage of Ti is 20%, and the rest is Ti. The mixed powder was prepared by the ball milling process, the ball-to-material ratio was 4:1; the rotation speed was 400 rpm, and the ball milling time was 180 minutes. A TC4 titanium alloy plate substrate is selected, and the size of the substrate is 200mm×80mm×20mm. The surface of the substrate is polished with a grinder, and then cleaned with acetone. An 8kW high-power semiconductor laser cladding system (LaserlineLDF-8000) is selected, the scanning speed is 4mm / s, the laser power is 2kW, and the powder feeding rate is about 12g / min. The whole laser cladding process is carried out under the protection of argon. The friction pair selected in the friction and wear test is corundum ceramics, the test load is 50N, the speed is 200rpm, and the test time is 60min. The high-temperature oxidation weight gain was tested at 650°C, 700°C, 750°C...

Embodiment 2

[0037] LaB 6 pre-added in Ti+AlB 2 Laser cladding powder, LaB 6 1.5% by mass, AlB 2 The mass percentage of Ti is 20%, and the rest is Ti. The mixed powder was prepared by the ball milling process, the ball-to-material ratio was 4:1; the rotation speed was 400 rpm, and the ball milling time was 180 minutes. A TC4 titanium alloy plate substrate is selected, and the size of the substrate is 200mm×80mm×20mm. The surface of the substrate is polished with a grinder, and then cleaned with acetone. An 8kW high-power semiconductor laser cladding system (LaserlineLDF-8000) is selected, the scanning speed is 4mm / s, the laser power is 2kW, and the powder feeding rate is about 12g / min. The whole laser cladding process is carried out under the protection of argon. The friction pair selected in the friction and wear test is corundum ceramics, the test load is 50N, the speed is 200rpm, and the test time is 60min. The high-temperature oxidation weight gain was tested at 650°C, 700°C, 750...

Embodiment 3

[0039] LaB 6 pre-added in Ti+AlB 2 Laser cladding powder, LaB 6 4.5% by mass, AlB 2 The mass percentage of Ti is 20%, and the rest is Ti. The mixed powder was prepared by the ball milling process, the ball-to-material ratio was 4:1; the rotation speed was 400 rpm, and the ball milling time was 180 minutes. A TC4 titanium alloy plate substrate is selected, and the size of the substrate is 200mm×80mm×20mm. The surface of the substrate is polished with a grinder, and then cleaned with acetone. An 8kW high-power semiconductor laser cladding system (LaserlineLDF-8000) is selected, the scanning speed is 4mm / s, the laser power is 2kW, and the powder feeding rate is about 12g / min. The whole laser cladding process is carried out under the protection of argon. The friction pair selected in the friction and wear test is corundum ceramics, the test load is 50N, the speed is 200rpm, and the test time is 60min. The high-temperature oxidation weight gain was tested at 650°C, 700°C, 750...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com