Preparation method of proton-exchanging membrane fuel-cell catalyst composite carrier

A proton exchange membrane and fuel cell technology, applied in the field of electrochemistry, can solve the problems of uneven distribution of metal oxides, affecting the performance of active components of catalysts, etc., achieving easy control of the preparation process, simple and easy operation of the preparation method, and improved oxygen reduction activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a proton exchange membrane fuel cell catalyst composite carrier, comprising:

[0024] mixing the carrier base material with the heteropoly acid solution, mixing evenly and then filtering to obtain the carrier base material impregnated with the heteropoly acid;

[0025] The carrier substrate impregnated with the heteropolyacid is burned in an inert atmosphere to obtain the proton exchange membrane fuel cell catalyst composite carrier.

[0026] The present invention uses a liquid heteropolyacid solution as the source of metal oxides, mixes the heteropolyacid solution with the carrier substrate, makes the surface of the carrier substrate adsorb the heteropolyacid solution, then mixes evenly, and finally impregnates the The carrier substrate of the heteropolyacid solution is sintered. Heteropolyacids are a type of oxygen-containing polyacids composed of heteroatoms and polyatoms in a certain structure through the coordination b...

Embodiment 1

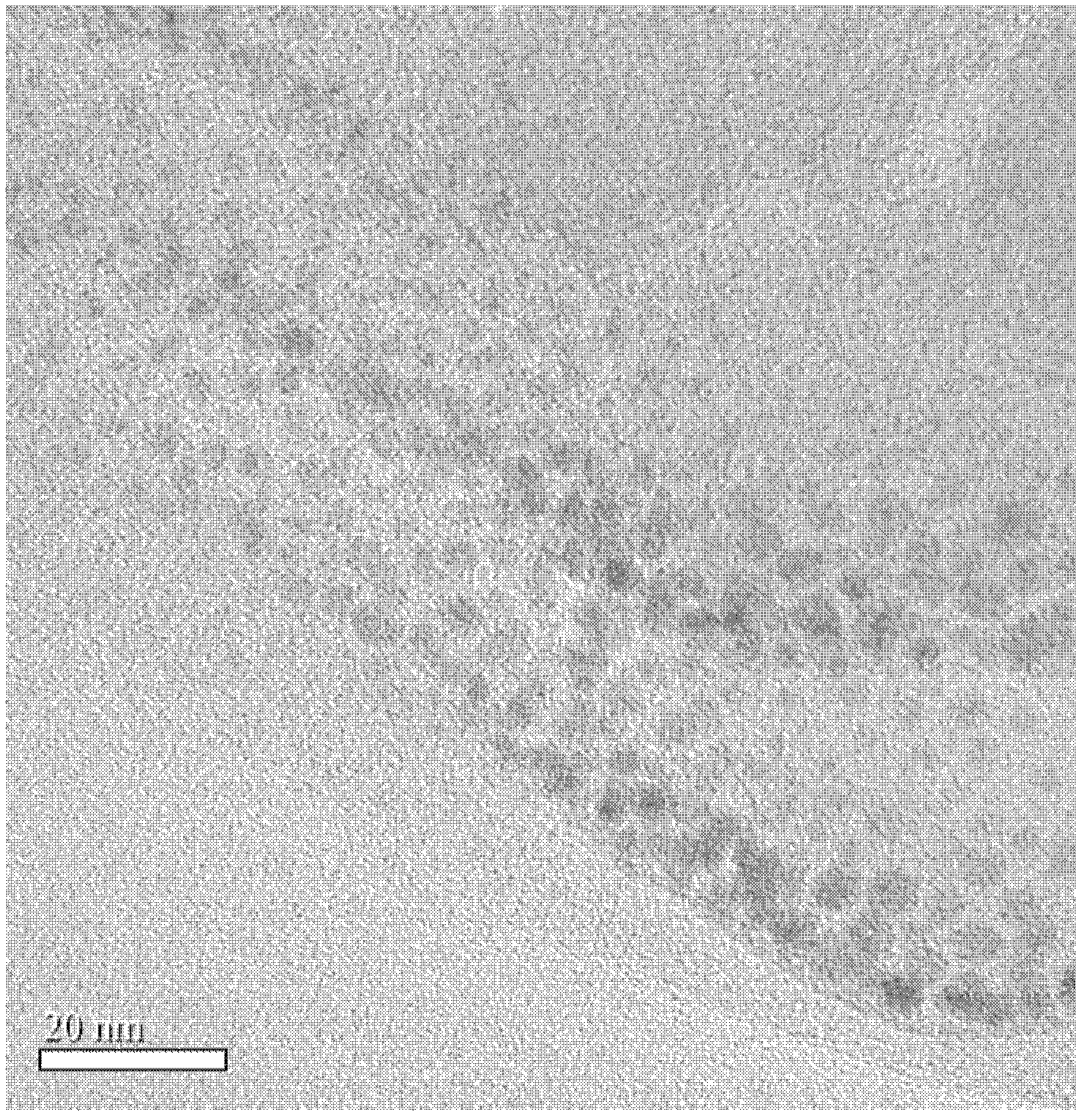

[0033] WO 3 Preparation and properties of -C complex carrier. Weigh 1g of activated carbon and add it to 50ml of 40mg / ml phosphotungstic acid solution, stir at room temperature for 6 hours, filter, do not wash with water, and dry in vacuum at 80°C for 4 hours, then the product is transferred to a tube furnace and heated at 600°C under nitrogen Heat treatment under protection for 4 hours. When phosphotungstic acid is heat-treated above 500°C, the decomposition product is WO 3 , so the product after heat treatment in the tube furnace is WO 3 -C composite carrier. figure 1 is the produced WO 3 TEM image of -C. It can be seen from the figure that WO 3 Evenly dispersed on the surface of activated carbon.

Embodiment 2

[0035] MoO 3 - Preparation of CNT composite carrier. The heteropoly acid is phosphomolybdic acid, the carbon material is multi-walled carbon nanotubes, and other preparation processes are the same as above.

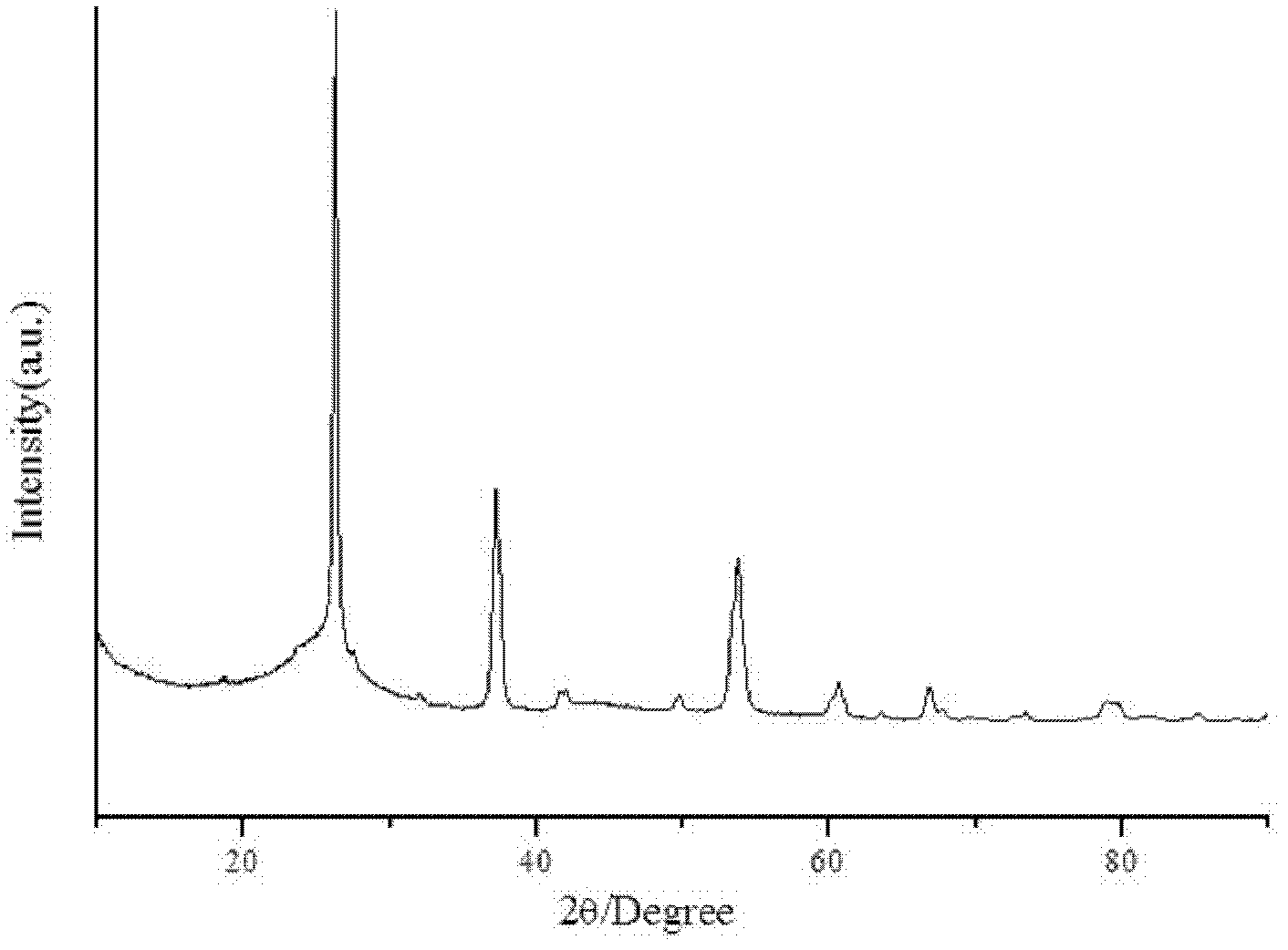

[0036] figure 2 for MoO 3 -XRD pattern of CNT composite carrier, MoO can be seen from the figure 3 The diffraction peaks of the MoO 3 The existence of; 25° is the diffraction peak of the carbon (002) crystal plane, which proves the existence of carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com