Lithium ion battery anode material and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, batteries, secondary batteries, etc., can solve the problems of unsuitable preparation process, poor electrode cycle performance, poor structural stability, etc., and achieve good ion/electronic conduction. effect, improving electrical conductivity and structural stability, and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

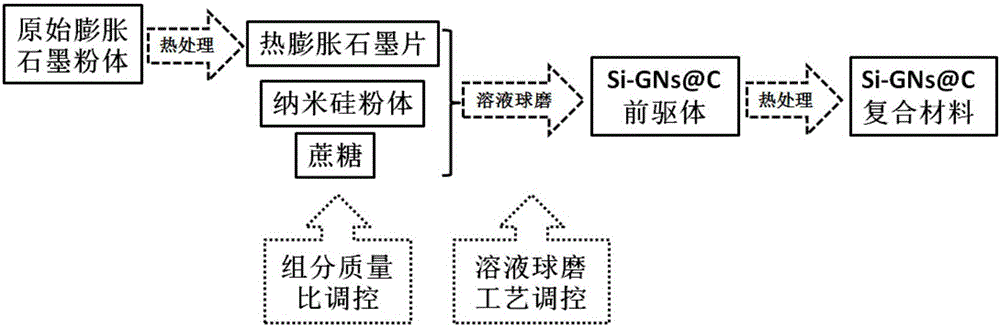

Method used

Image

Examples

Embodiment 1

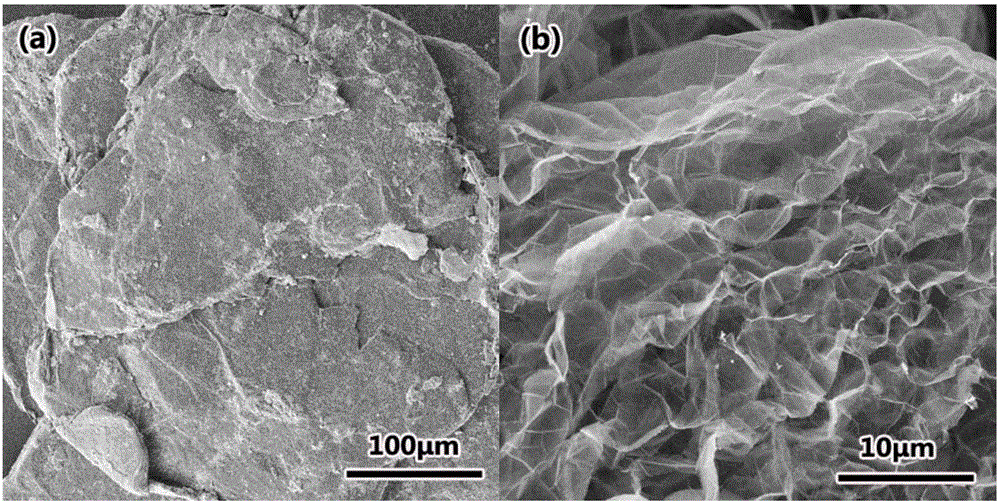

[0041] The original expanded graphite powder with a purity of 99.9% and a particle size of 100 mesh was heated at a high temperature (1000° C.) for 2 minutes under the protection of argon to obtain a thermally expandable graphite sheet. For comparison of expanded graphite before and after heat treatment, see figure 2 . Depend on figure 2 It can be seen from the comparison photos of the scanning electron microscope that the heat-treated expanded graphite has a loose graphene-like structure, which is suitable as a buffer flexible matrix for silicon-based composite materials.

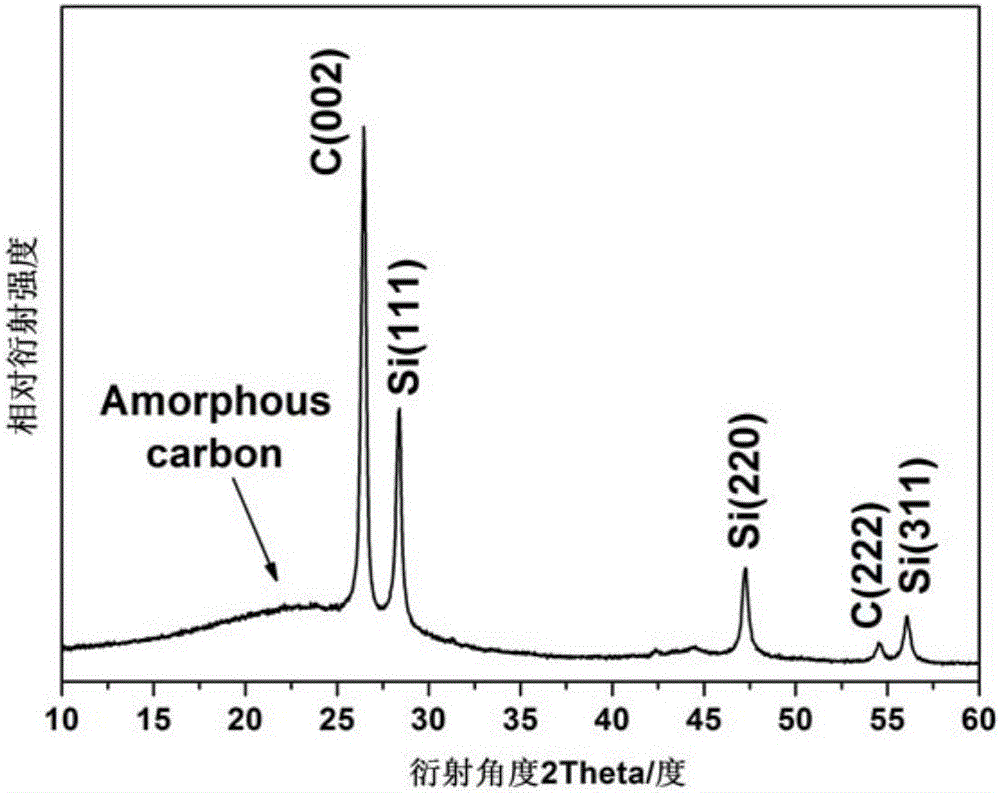

[0042]2g of the above-mentioned heat-expandable graphite sheets, 2g of nano-silicon powder with a purity of 99.9%, a particle size of ~80 nanometers, and 15g of sucrose with a purity of 99.9% are added to a mixed solution (200ml of ethanol and deionized water volume ratio 1:1 ) and carry out solution ball milling, the ball-to-material ratio is 40:1, the ball mill speed is 1200rpm, and the ball milling t...

Embodiment 2

[0045] The original expanded graphite powder with a purity of 99.9% and a particle size of 100 mesh was heated at a high temperature (1000° C.) for 2 minutes under the protection of argon to obtain a thermally expanded graphite sheet.

[0046] Add 2.5g of the above thermally expandable graphite sheet, 2.5g of silicon powder with a purity of 99.9% and a particle size of ~80nm, and 12.5g of sucrose with a purity of 99.9% to a mixed solution of ethanol and deionized water at a volume ratio of 1:1 (200ml) and carry out solution ball milling, the ball-to-material ratio is 60:1, the ball mill speed is 1200rpm, and the ball milling time is 2 hours; then dry and heat to 600°C for 60 minutes under argon and keep it warm for 2 hours for carbonization to obtain Si- GNsC composite material; the nano-silicon mass accounts for 25% of the total mass of the Si-GNsC composite material; the graphene nanosheet accounts for 25% of the total mass of the Si-GNsC composite material; the amorphous car...

Embodiment 3

[0050] The original expanded graphite powder with a purity of 99.9% and a particle size of 100 mesh was heated at a high temperature (1000° C.) for 3 minutes under the protection of argon to obtain a thermally expanded graphite sheet.

[0051] Add 3 g of the above thermally expandable graphite sheets, 3 g of silicon powder with a purity of 99.9% and a particle size of ~80 nanometers, and 10 g of sucrose with a purity of 99.9% into a mixed solution (200 ml) of ethanol and deionized water at a volume ratio of 1:1 and carry out solution ball milling, the ball-to-material ratio is 60:1, the ball mill speed is 1200rpm, and the ball milling time is 3 hours; then dry and heat to 700°C under argon for 60 minutes and keep it warm for 3 hours for carbonization to obtain Si-GNsC composite material The nano-silicon mass accounts for 30% of the total mass of the Si-GNsC composite material; the graphene nanosheet accounts for 30% of the total mass of the Si-GNsC composite material; the amorp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com