Light high-strength composite pipe and production method thereof

A high-strength, composite pipe technology, applied in the direction of slender elements, building elements, etc., can solve the problems of wasting raw materials, increasing the weight of the roller body, and making it difficult for the roller body to rotate normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

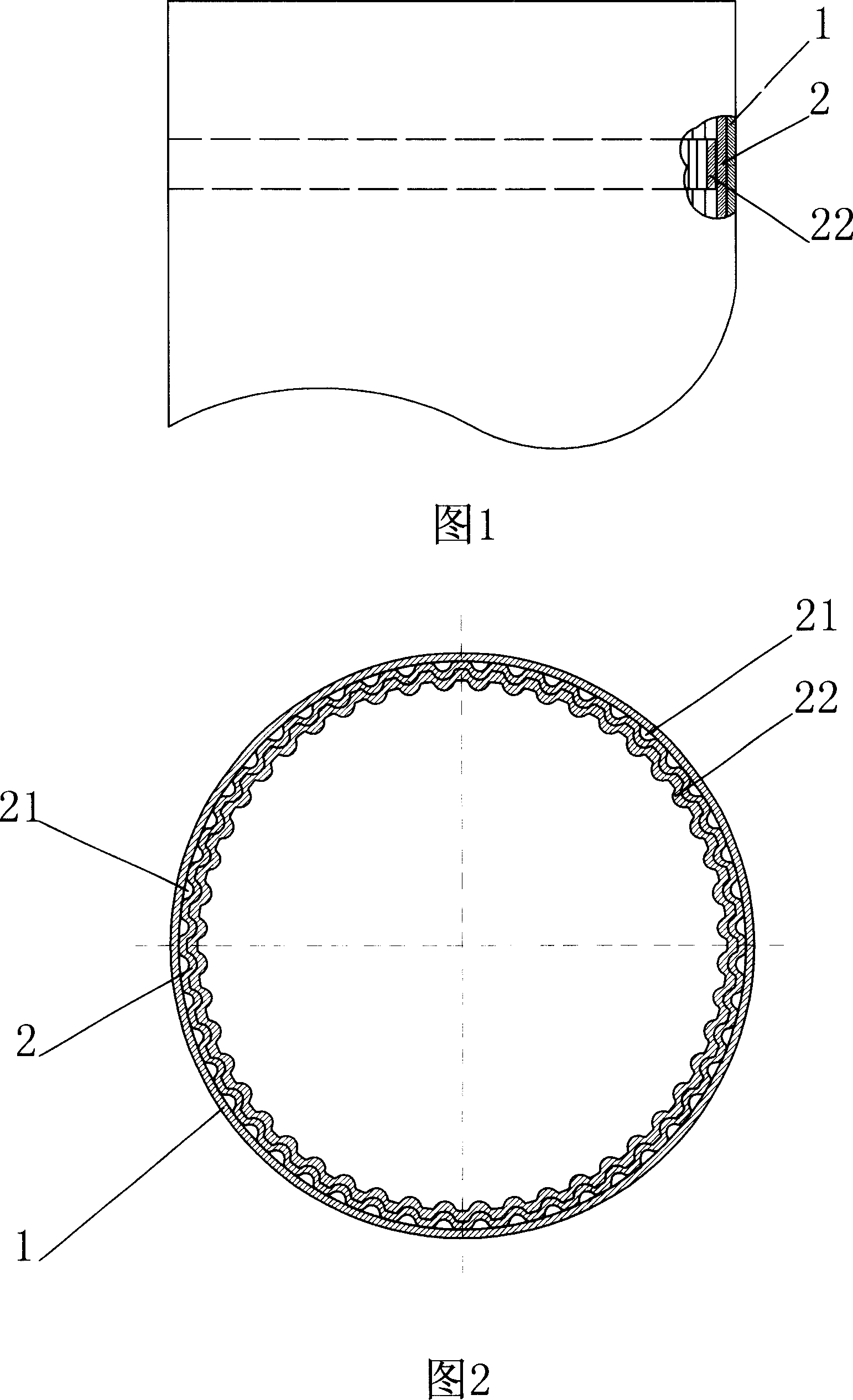

[0017] As shown in Figure 1, Figure 2, Figure 3, and Figure 4, a light-duty high-strength composite pipe is composed of double-layer steel coiled pipes, the outer layer is made of thin stainless steel coiled pipe 1, and the inner layer is made of thin carbon steel plates The coiled tube 2 is formed, and according to the diameter and length of the roll body, the inner thin carbon steel coiled tube is made with several reinforcement tubes in alternate shapes of concavo-convex 21 .

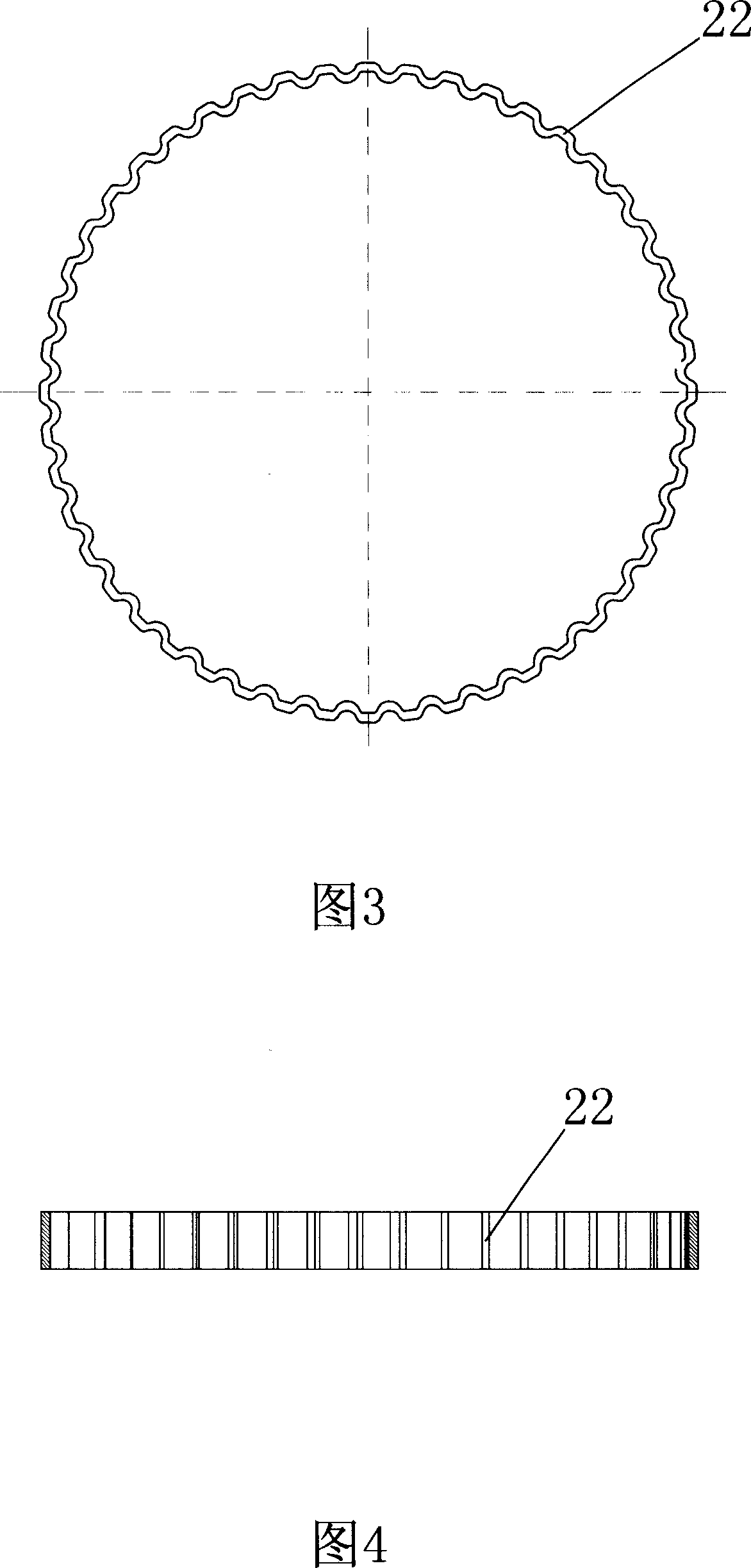

[0018] In order to increase the radial strength and the roundness of the pipe body, several support hoops 22 are added in the thin carbon steel pipe.

[0019] Wherein the cross section of concave-convex groove 21 is semicircular, also can be U-shaped, triangular, trapezoidal etc.

[0020] A manufacturing method of a lightweight high-strength composite pipe is as follows:

[0021] 1. Cut the material according to the size. 2. Use the mold with several alternating concave and convex shapes to make the...

Embodiment approach 2

[0024] Manufacture Ф150×2000mm cloth guide roller tube body, material selection: the outer layer is 1mm stainless steel plate, the inner layer is 1mm carbon plate, the manufacturing method of a light-duty high-strength composite tube is as follows:

[0025] 1. Cut the material according to the size, take 1mm carbon steel plate 2. Use the mold with several concave and convex alternate shapes to make the blanked plate into a plate with several concave and convex alternate shapes, and leave a margin for the next stretching and shaping 3. Trim the edge according to the unfolded size 4. Roll it into a cylinder with a mold, 5. Spot weld and weld the clamping roller body 6. Make the inner roller decently under the action of tension, and use a concave-convex mold for shaping 7. Under the action of tension, the roller body is cold-extruded with a mold to meet the required size requirements for compounding with the outer roller body to form the inner roller body. 8. Fix the outer roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com